Website:

Elettronica Todescato

Website:

Elettronica Todescato

Catalog excerpts

INDEX SECTION 1: Description and main features of the welder 1.1 Presentation 1.2 Warranty 1.2.1 Exclusion from warranty 1.3 Machine identification 1.4 Equipment 1.5 Machine description and use limitation 1.5.1 Description 1.5.2 Use limitation 1.6 Noise 1.7 Technical features SECTION 2: Safety and prevention 2.1 Safety 2.1.1 General safety regulations 2.2 Safety signs (Symbols) 2.3 Safe use and maintenance SECTION 3: Transport and installation 3.1 Packaging 3.2 Shipping 3.3 Unpackaging 3.4 Positioning 3.5 Storing SECTION 4: Use 4.1 Connection to the electric circuit 4.2 Preparing the...

Open the catalog to page 3

SECTION 1 Description and main features of the welder 1.1 PRESENTATION This manual gives information regarded as necessary to know, use correctly and carry out normal maintenance operations on this welder « L/45 » (hereinafter referred to as machine) fabricated by «Elettronica Todescato S.r.l.» di Arcugnano (Vicenza) Italy (hereinafter referred to as Manufacturer). The material in this manual is not intended to be a complete description of the parts nor a detailed explanation of their option. The user, however, will find the kind of information normally required to operate the machine...

Open the catalog to page 4

Upon delivery, make sure that the machine has not suffered damage during transportation and that it is complete with all standard accessories and any optional equipment specifically ordered. Complaints must be written and submitted to your reseller within and not later than 8 (eight) days. 1.2.1 EXCLUSIONS FROM WARRANTY This warranty shall be null and void (apart from the causes given in the Purchase Contract): - If the machine is used with incorrect voltage. - If the damage is due to insufficient maintenance or lack of proper service. - If, following repairs carried out by the owner...

Open the catalog to page 5

Three-position switch Safety cap Filling neck Power control knob Minimum level indicator light (yellow) Maximum level indicator light (red) Booster Tank Handle knob Booster holder 10. Torch 11. Burner tip 12. On indicator light (green) 13. Check valve cap 14. Torch holder (optional) 15. Torch hose 16. Torch hose fitting 17. Booster holder hose fitting 21. Identification plate

Open the catalog to page 6

1.4 EQUIPMENT Standard equipment - Burner tip (Fig. 1 # 11). User manuals and DVD. Spare fuse (Fig. 5 # 37). Plastic funnel. Torch (s). Fire proof rubber hose. Power cord. Container with distilled / demineralized water. Container with liquid flux (deoxidizer). Torch holder (14 Fig. 1). 2.5 Bar pressure gauge. Electrolyte solution. One year maintenance kit. Ignitor. 1.5 MACHINE DESCRIPTION AND USE LIMITATION The «ET- hydrogen L/45 Welder is a machine marked with « CE» symbol i n compliance with E u r o p e a n Union regulations pursuant to EEC Directive 2014/35/UE and 2014/30/CE as detailed...

Open the catalog to page 7

DANGER Any use different from those quoted here within and not included or not directly inferred from this instructions’ manual, will be regarded as «NOT ALLOWED». It is not permitted to operate the machine when the flame is out. This would result in an accumulation of explosive mixture in the surrounding environment and pollution caused by the methyl alcohol. The machine has been designed for professional use. The operator must be of proven ability and capable of reading and understanding the instructions given in this manual. The operator must also use the machine in accordance with the...

Open the catalog to page 8

H2/O2 Gas production Water consumption Alcohol consumption Booster tank capacity Maximum power Electrolyte Weight

Open the catalog to page 9

SECTION 2 Safety and Prevention 2.1 SAFETY The owner of the machine must instruct personnel about the risk of industrial accident, the safety device installed for operator safety and on general industrial accident prevention regulations applied by law in the country where the machine is to be operated. Operator safety is a matter of considerable importance for machine design and fabrication. When designing a new machine, every effort is made to foresee every possible dangerous situation and, naturally, adopt suitable safety devices to counter them. Therefore, a careful reading of this...

Open the catalog to page 10

The user must inform the Manufacturer of any defects or malfunctions in the accident prevention system and any situations of potential danger. The personnel must use the personal protection items provided for by law and respect instructions given in this manual. The personnel must respect the danger and caution symbols on the machine. The personnel must not perform operations or interventions under their own initiative that lie outside their competence. The personnel is obliged to notify superiors of any problem or dangerous situation that may arise. The machine has been commissioned and...

Open the catalog to page 11

ATTENTION The use of the machine is prohibited to: o Operators who have not read and understood the instructions given in this manual; o Inexperienced persons; o Operators not in good physical/mental health. Periodically check that the machine and its protection devices are in perfect working order. Before maintenance operations or repairs on the machine, disconnect power. Maintenance operations and repairs must only be carried out by personnel trained to perform these special functions. At the end of the maintenance operations and repairs, before restarting the machine, the technical...

Open the catalog to page 12

SECTION 3 Transport and Installation 3.1 PACKAGING The welder is wrapped up in a polythene film and subsequently packed in a three-layer waterproof cardboard box sealed with adhesive tape and secured by a double strap. 3.2 SHIPPING Whatever transportation method is used, (either by plane, sea or land) continental or intercontinental, the machine tanks will be empty. If REQUESTED or where PERMITTED: The packaged electrolyte salts and/or bottled demineralized water, will be shipped according to the rules, law and regulations of the machine’s destination (country). 3.3 UNPACKAGING Make sure...

Open the catalog to page 13

SECTION 4 Use 4.1 CONNECTION TO THE ELECTRIC CIRCUIT Check that the main voltage corresponds to the voltage indicated on the plate at the rear of the welder (Fig. 1 # 21). Test the electrical circuit grounding to make sure that is it efficient. - Slide the switch (Fig.1 # 1) to the “O” position. - Insert power cable plug (Fig.5 # 31) into the current outlet. 4.2 PREPARING THE ELECTROLYTE Pour 180 grams of KOH (Potassium Hydroxide) into a clean stainless-steel vessel and/or hard plastic container that has been previously filled with 0,445 liters (0.118 US gal) of distilled or demineralized...

Open the catalog to page 14All Elettronica Todescato catalogs and technical brochures

-

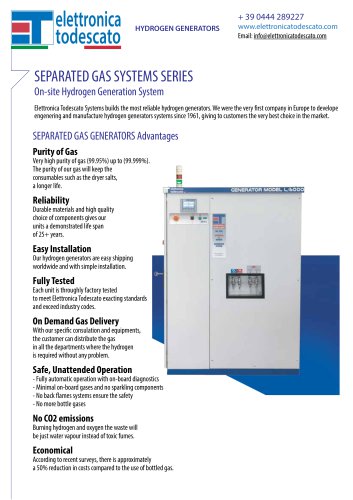

SEPARATED GAS SYSTEMS SERIES

2 Pages

-

HYDROGEN & OXYGEN GENERATORS

2 Pages