Catalog excerpts

P R E C I S I O N M A C HININ G & F INI S HIN G Precision Machining GIVING TOOLMAKERS A COMPETITIVE EDGE —— With PCD, PCBN, CVD Diamond & Single Crystal Diamon

Open the catalog to page 1

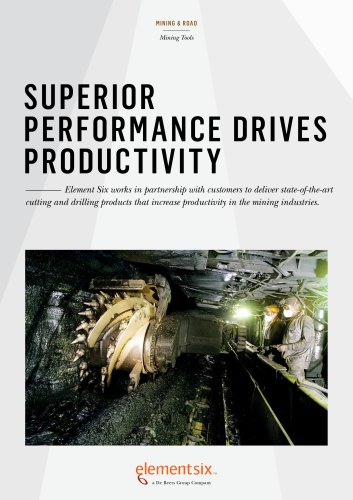

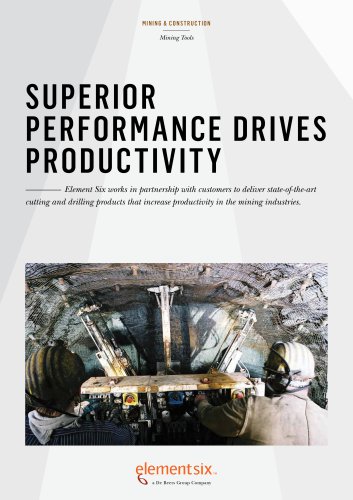

Element Six works in partnership with customers to develop cutting-edge products and materials that offer considerable advantages over their competitors. Element Six has a proven commitment and capacity to innovate and continues to deliver ground breaking commercial opportunities. The unique Element Six state-of-the-art Global Innovation Centre (GIC) near Oxford (UK), further enhances our position as the world leader in synthetic diamond and supermaterials research to find new ways to turn the extreme properties of supermaterials into products with revolutionary performance. Element Six...

Open the catalog to page 3

GRADE APPLICATIONS CHARACTERISTICS MICROSTRUCTURE CDE PL Application areas are the An electrically conducting grade of machining of laminated flooring, CVD for cutting tool applications fibre and cement boards. that allows customers to use EDM machining or EDG grinding within their tooling processing. CDM PL Successful in the machining A general purpose mechanical grade of metal matrix composites, for cutting tools. aluminium alloys, glass reinforced plastics and carbon fibre based materials. Precision Machining

Open the catalog to page 4

SELECTING PRODUCTS & GRADES FOR YOUR APPLICATIONSPCD / CVD GRADE SELECTION CUTTING CONDITIONS AND EDGE DESIGN NON FERROUS METALS HYPOEUTECTIC (SI< 12%) AND EUTECTIC (SI =12%) SILICON ALLOYS CERAMIC MACHINING (GREEN) CERAMIC MACHINING (SINTERED) COPPER AND ITS ALLOYS MAGNESIUM AND ITS ALLOYS GREY & HIGH STRENGTH IRONS COMPOSITE PLASTICS CUTTING SPEED (M/MIN) 11 ml i LEGEND F=up-sharp E=honed edge Y=tool top rake angle P a = clearance angle Work material characteristics and to a lesser extent, cutting parameters, determine the demands placed on the cutting tool and hence, the optimum balance...

Open the catalog to page 5

PCD LAYER PROFILE Element Six supplies a unique ultrasonic scan depicting the PCD layer profile. The PCD scan indicates a ‘North Point’, which matches a ‘North Point’ laser marked on the disc, allowing users to optimise the cutting areas.

Open the catalog to page 6

PCD GRADES FOR WIDER USAGE Improvements in synthesis techniques coupled with new product development capability has resulted in CMX850 and CTM302 having the properties to meet all of the challenges in tool performance. CTM302 provides the ultimate abrasion resistance while CMX850 provides the optimum balance of processability and performance. THE 4 MAIN FACTORS FOR CONSIDERATION WHEN SELECTING PCD GRADES: - Chip resistance Behaviour in Application - Abrasion resistance - Electro-discharge characteristics Processing - Grindability characteristics Characteristics SUPER FINISHING GENERAL...

Open the catalog to page 7

AERO -DIANAMIC S - PCD ROUND T OOL S BL ANKS GR A DE S A ND CH A R AC T ERI S T IC S GRADE GRAIN SIZES –– Up to 250 times wear resistance compared with traditional tungsten carbide end mills –– Up to 12 times faster machining speeds –– Tubular configuration gives virtually infinite possibilities for flute angles & orientations –– Helical geometry results in lower tool forces and better chip evacuation –– High thermal conductivity and low coefficient of friction results in less heat build-up and adhesion –– Sharp PCD edges cut fibres cleanly –– Tool life extended 10 times longer than Carbide...

Open the catalog to page 8

SE T T ING T OOL DESIGN FREE Our Aero-Dianamics range of round tool blanks provides tool designers the ability to create entirely new PCD tool geometries which break through existing barriers in PCD tool design with: –– Freedom of design in flute profiles –– Multiple flutes –– Limitless flute angles and orientations A E R O - DI A N A MIC S - T R A N S F ORMING C OMP O S I T E T O OL ING These next generation composite tooling solutions entirely replace the need for coated tungsten carbide tools for fabricating composite components. 3D TUNGSTEN CARBIDE TOOL PCD ROUND TOOLS BLANKS UNIQUE A D...

Open the catalog to page 9

C V D DIAMOND GR ADES AND CHAR AC T ERIS T IC S GRADE Wide-ranging laser cut shape and size for Precision machining of MMC, CFRP and woodworking materials. An electrically conducting grade of CVD for cutting tool applications, that allows customers to use EDM machining or EDG grinding within their tooling processing. Wide-ranging laser cut shape and size for Precision machining of MMC and CFRP materials. A general purpose mechanical grade for cutting tools. BE NE F I T S OF E L EMEN T S I X C V D DI A MOND: C V DI T E –– Higher wear resistance than medium PCD grades –– Extreme abrasion...

Open the catalog to page 10

SINGLE CRYS TAL DIAMOND GR ADES AND CHAR AC T ERIS T IC S S INGL E CRYS TA L MC C A P P L I C AT I O N S MCC is available in 2pt and 4pt orientations. Ultra precision machining acrylics, copper, germanium. Generates very high surface finishes. Produced under ultra-high purity conditions, which gives it its colourless appearance. It offers a combination of extreme wear resistance, excellent chip resistance and high thermal conductivity combined with low thermal expansion. Primary applications for Monodite are engineered cutting tools and wear parts for super finishing, burnishing, wire...

Open the catalog to page 11

PCBN WC BACKED DISC PRODUCT RANGE GRADE OUTSIDE DISC PCBN USABLE PCBN LAYER DIAMETER (MM) AREA (MM) (MM) PCBN SOLID LOW CONTENT PRODUCT RANGE GRADE CONDUCTIVE / OVERALL THICKNESS (+/- 0.05MM) OUTSIDE DISC PCBN USABLE NON-CONDUCTIVE u u 2.38 3.18 4.76 6.35 7.94 DIAMENTER (MM) AREA (MM) PCBN SOLID HIGH CONTENT PRODUCT RANGE GRADE CONDUCTIVE / OVERALL THICKNESS (+ / - 0.13MM) OUTSIDE DISC PCBN USABLE AREA PCBN SYNSCAN Element Six supplies a unique ultrasonic scan depicting the PCBN layer profile. The PCBN scan indicates a ‘North Point’, which matches a...

Open the catalog to page 12

For moderately interrupted hard turning and finish hard milling as well as high speed continuous turning. Its resistance to crater wear is among the highest in the market. With one of the finest structures of all commercial grades, DCN450 provides for sub-pm surface roughness. Approximately 45% CBN Sub-pm CBN grain size TiCN binder For continuous and lightly interrupted cutting of the majority of automotive steels. Excellent abrasion resistance makes it the ideal choice for cold work tool steels and certain valve seat alloys. Also recommended for finishing abrasive high strength cast irons....

Open the catalog to page 13All Elementsix catalogs and technical brochures

-

PURECUT DHA650

2 Pages

-

Milling

2 Pages

-

Drilling

3 Pages

-

DiafilmTM ETC700

2 Pages

-

D Power Road Pick

8 Pages

-

Micron Capabilities

2 Pages

-

CVD diamond heat spreaders

2 Pages

-

PDC Cutters

6 Pages

-

PCD and PCBN segments

2 Pages

-

ENABLE THE IMPOSSIBLE

4 Pages

-

SOUNDS LIKE A DIAMOND

8 Pages

-

Tungsten carbide rolls

4 Pages

-

Element Six coated

2 Pages

-

NEXT GENERATION MICRON+

8 Pages

-

Monodress MDL

2 Pages

-

Monodress Macles

2 Pages

-

ABN 900

3 Pages

-

Percussive Diamond Inserts

4 Pages

-

PCD oil & gas MSDS

5 Pages

-

Oil and Gas capabilities

8 Pages

-

PCD metalworking MSDS

5 Pages

-

Diafilm OP Brochure

4 Pages

-

Optical Brochure

6 Pages

-

Diamond etalons brochure

2 Pages

-

Premadia brochure

8 Pages

-

Road planing picks

12 Pages

-

PCD drill bits

8 Pages

Archived catalogs

-

Mining Tools_2016

28 Pages

-

Mining Tools_2014

12 Pages