Catalog excerpts

MININ G & R OA D D Power TM Road Picks THE COMPETITIVE EDGE THROUGH CUTTING EDGE TECHNOLOGY ——-------— D Power TM Road Picks deliver consistent performance and over 40x life giving you the competitive ed

Open the catalog to page 1

THE POW ER T O R AISE YOUR PRODUC T I V IT Y AND PROFI TABILI T Y Gain the competitive edge on road milling projects with D Power TM Road Picks that deliver consistent performance and life. –– Competitive advantage through increased pick life and productivity –– Improve fuel efficiency Element Six’s D Power Road Picks, proven in a number of markets around the world, last over 40 times longer than standard carbide picks. Our cutting edge technology and synthetic diamond innovation enables customers to complete projects quicker and to a higher standard than their competitors. TM –– Deliver...

Open the catalog to page 2

7 RE ASONS T O CHOOSE D POW ER T M YOUR C OMPE T I T I V E A D VA N TAGE Outperform your competitors. Road tested and road proven, projects are completed quicker with less machine downtime and improved productivity. Less time on-site, means less road construction disruptions. L ONGE R PICK L IF E A dramatic extension of pick life – D Power TM lasts over 40x standard carbide picks. Thanks to Element Six’s unique combination of synthetic diamond and tungsten carbide expertise, you can realise the maximum value of the extended pick life and achieve the lowest lifetime cost. Element Six D...

Open the catalog to page 3

POW ERFUL PROOF R E V OL U T IONI S ING MIL L ING A R OUND T HE W OR L D Over 25 leading road contractors in over 10 countries have revolutionised their road milling activity with D Power TM . Read about just some of our customers’ experiences and how they are transforming their productivity, profitability and competitive advantage thanks to D Power TM . A RACE AGAINST TIME On average, every night they would have to stop twice to change worn picks on their planing machines. As the picks began to wear the quality of the work would deteriorate noticeably. These factors were impacting...

Open the catalog to page 4

D POW ER™ ROAD PICKS “The results of our first project were very impressive.” EUROPEAN CUSTOMER REPORT ROAD CUTTER LIFE: “…the machine operators were the first to be sold on them mainly because they can just get on with the job without stopping to spot or change.” Standard Carbide Road Picks D Power TM Road Picks “On one jobsite we ran D PowerTM on milling machines 24 hours a day over a period of several days.” Based on European testing programme. “For us the big pay-off is the improved productivity we get while working on site.” “Element Six insisted their picks would last over 40 times as...

Open the catalog to page 5

THE POW ER OF SY N THE TIC DIAMOND –– Extreme wear resistance combined with immense toughness –– Synthesised by high pressure high temperature manufacturing –– Extensive lab tests and on-site experience prove the superior performance properties Our customers benefit from Element Six’s unrivalled synthetic diamond production facilities to meet their specific requirements. HO W SY N T HE T IC DI A MOND H A S T R A N S F ORMED O T HER INDU S T R IE S PERFORMANCE IMPROVEMENTS IN OIL & GAS Element Six synthetic diamond drill bits increase penetration rates and enable ‘one bit drilling’ in...

Open the catalog to page 6

THE POW ER OF ELEMEN T SI X E L EME N T S I X ™ Element Six is the world leader in synthetic diamond supermaterials and one of the major players in tungsten carbide manufacturing. For over 20 years, Element Six has been offering road contractors an unrivalled portfolio of road milling & soil stabilisation picks, which includes our globally renowned MasterGrade® range. D Power™ Road Picks are the latest addition to our successful portfolio. Element Six is a member of the De Beers Group of Companies and we manufacture in China, Germany, Ireland, South Africa, US and the UK. D Power TM Road...

Open the catalog to page 7

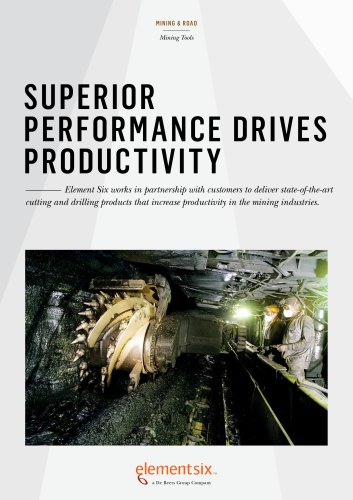

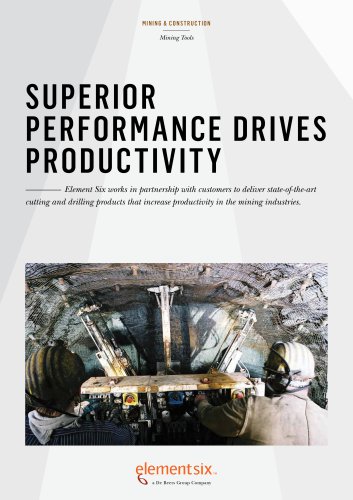

ELEMENT SIX Element Six is a synthetic diamond supermaterials company and a member of the De Beers Group of Companies. Element Six designs, develops and produces synthetic diamond supermaterials, and operates worldwide with its head office registered in Luxembourg, and primary manufacturing facilities in China, Germany, Ireland, South Africa, US and the UK. Element Six supermaterial solutions are used in applications such as cutting, grinding, drilling, shearing and polishing, while the extreme properties of synthetic diamond beyond hardness are already opening up new applications in a wide...

Open the catalog to page 8All Elementsix catalogs and technical brochures

-

PURECUT DHA650

2 Pages

-

Milling

2 Pages

-

Drilling

3 Pages

-

DiafilmTM ETC700

2 Pages

-

Micron Capabilities

2 Pages

-

CVD diamond heat spreaders

2 Pages

-

PDC Cutters

6 Pages

-

PCD and PCBN segments

2 Pages

-

ENABLE THE IMPOSSIBLE

4 Pages

-

SOUNDS LIKE A DIAMOND

8 Pages

-

Tungsten carbide rolls

4 Pages

-

Element Six coated

2 Pages

-

NEXT GENERATION MICRON+

8 Pages

-

Monodress MDL

2 Pages

-

Monodress Macles

2 Pages

-

ABN 900

3 Pages

-

Percussive Diamond Inserts

4 Pages

-

PCD oil & gas MSDS

5 Pages

-

Oil and Gas capabilities

8 Pages

-

PCD metalworking MSDS

5 Pages

-

Diafilm OP Brochure

4 Pages

-

Optical Brochure

6 Pages

-

Diamond etalons brochure

2 Pages

-

Premadia brochure

8 Pages

-

Road planing picks

12 Pages

-

PCD drill bits

8 Pages

Archived catalogs

-

Mining Tools_2016

28 Pages

-

Mining Tools_2014

12 Pages