Website:

Electro-Sensors

Website:

Electro-Sensors

Catalog excerpts

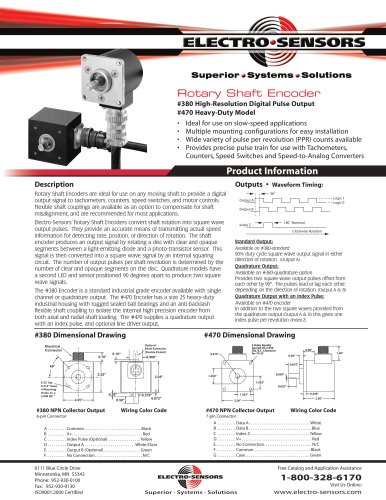

Reliable Products Trustworthy People Vibration Monitors Settable trip-point in RMS vibration velocity units (in/s) Settable over/under alarm function 2 output options: SPDT relay and isolated transistor Both output options are failsafe Settable alarm delay suppresses nuisance alarms At-a-glance power, vibration and output status 24 VDC powered 2 housing options: compact NEMA 4X and XP (explosion proof) XP Housing NEMA 4X Housing VS1 and VS2 monitor the machine surface to which they are attached and alarm when vibration either exceeds or falls below the trippoint setting, according to the alarm over/under switch setting. Each have three LED indicators providing power, vibration and alarm status. The isolated transistor or relay output may be wired for machine shutdown or as part of an early warning system. The adjustable alarm delay prevents false alarms by allowing the user to set the minimum continuous fault condition time for alarm, thus preventing needless system shutdowns during operation or startup. Two rugged cast aluminum housing options are available for the VS1 and VS2: the compact NEMA 4X and the Class I and II rated explosion proof (XP). A separate 24 VDC power supply is also available. VS1 The VS1 is a low-level vibration switch optimized to monitor non-intentionally vibrating machinery for the effects of imbalance, misalignment, looseness or wear (e.g. bearings). The trip-point setting range is 0.1→2.2 in/s. The VS1 is designed per ISO 10816-1 Mechanical Vibration - Evaluation of machine Vibration by measurements on nonrotating parts. VS2 The VS2 is a high-level vibration switch optimized to monitor intentionally vibrating machinery (e.g. vibratory conveyors, hammer-mills) for the effects of imbalance, excessive load, mechanical failure or unintended machine shutdown and alarm when vibration exceeds or falls below the trip-point setting. The trip-point setting range is 2.0→26 in/s. Installation VS1 and VS2 (NEMA 4X and XP Versions) Orientation IMPORTANT: VS-Series vibration monitors sense vibration along the axis indicated by the SENSING DIRECTION arrow. Orient the vibration monitor with the arrow parallel to the vibration axis to be monitored. Mounting: Rigid, tight attachment is necessary for any vibration-sensing device. For this reason, the VS-Series must be attached to a smooth, at surface. Any looseness or rocking will permit errorcausing resonance. Therefore, the VS-Series must be tightly and securely bolted to the measurement surface using ALL mounting tabs/holes. 6111 BLUE CIRCLE DRIVE

Open the catalog to page 1

Reliable Products Trustworthy People Vibration Monitors Green - indicates vibration above min. detectable level Red - output in alarm state Settings/Ranges Alarm Trip Point Alarm Delay Alarm 1 - 10 seconds Over / under select switch Operational Limits (Vibration) Min. Frequency (-3db) Max. Acceleration Cast Aluminum. NEMA 4X Cast Aluminum, CSA approved, UL Rated: Class I - Group C, D; Class II - Group E, F, G; Class III; NEMA 4X 5 A @ 250 VAC Relay energized when powered and not alarmed Failsafe Operating Temperature NPN Option Relay Option Relay Type ± 12 g peak (Relay Option) ± 50 g peak...

Open the catalog to page 2All Electro-Sensors catalogs and technical brochures

-

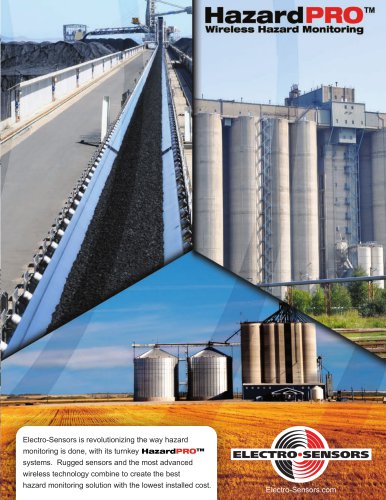

HazardProTm

12 Pages

-

Brochure ELECTRO SENSORS

40 Pages

-

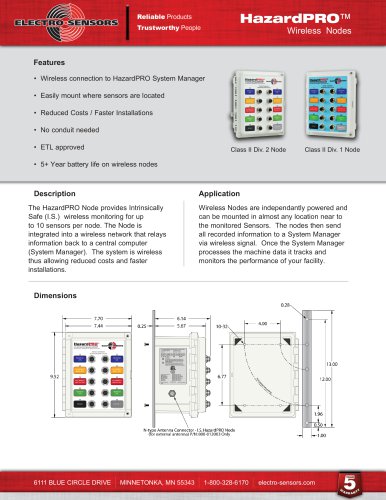

HAZARDPRO™ NODE

2 Pages

-

HAZARDPRO™ BEARING SENSOR

2 Pages

-

VTHP

2 Pages

-

DIGITAL RING KITS

3 Pages

-

Accu-Tach & Accu-Dial

2 Pages

-

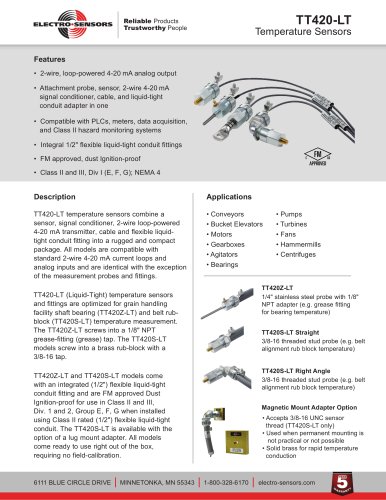

TT420-LT

2 Pages

-

TT420

2 Pages

-

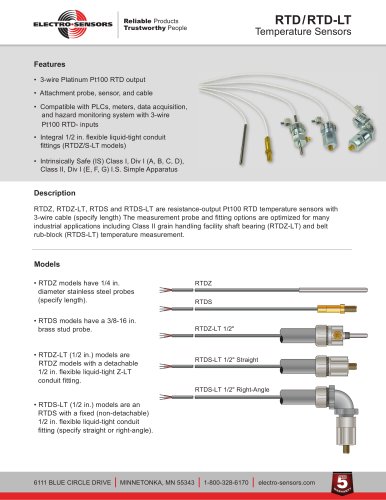

RTD/RTD-LT

2 Pages

-

PM500

2 Pages

-

SCP1000 / SCP2000

2 Pages

-

HH100 Hand-Held Tachometer

2 Pages

-

TR400

2 Pages

-

TR5000

2 Pages

-

SG1000A

2 Pages

-

SG1000B

2 Pages

-

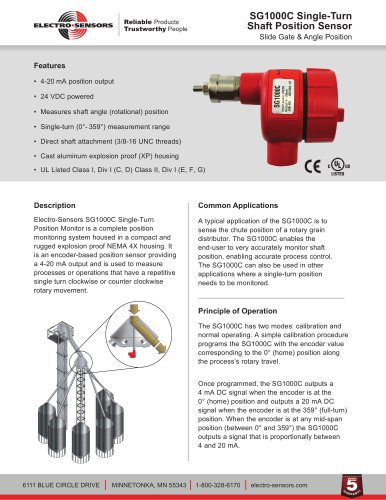

SG1000C

2 Pages

-

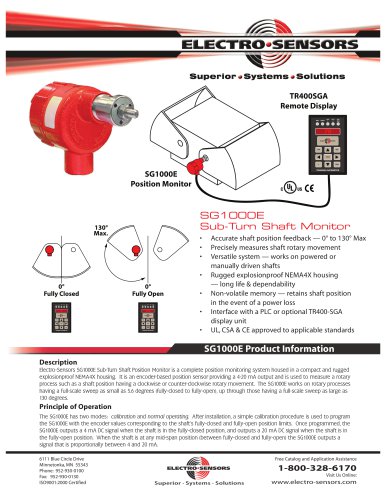

SG1000E

2 Pages

-

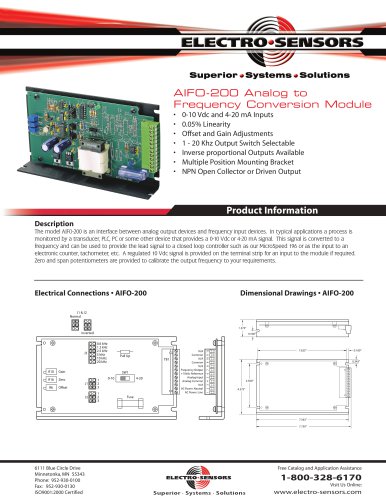

AIFO-200

2 Pages

-

MTS Series & SCU-200

2 Pages

-

VUM800

2 Pages

-

ION Remote I/O

2 Pages

-

SpeedTalker-DN(BH) DeviceNet

2 Pages

-

SpeedTalker-DN(UI)

2 Pages

-

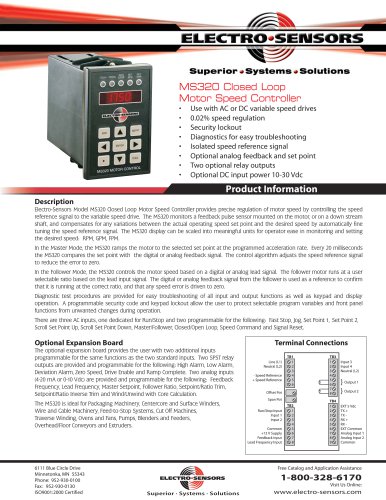

MS320

2 Pages

-

MS196

2 Pages

-

MS332

2 Pages

-

SpeedTalker-DN(XP) DeviceNet

2 Pages

-

SA420

2 Pages

-

LRB1000 / LRB2000

2 Pages

-

Stainless Steel Disc Guards

2 Pages

-

Shaft Speed Switch

12 Pages

-

Product Brochure

28 Pages

-

ION Modbus RTU I/O Modules

1 Pages

-

ST420 Shaft Tachometer

2 Pages

-

Sensors - 907 XP Hall-effect

2 Pages

-

Sensors - 1101 Hall-effect

2 Pages

-

Sensors - 608-1 Proximity Sensor

2 Pages

-

Sensors - 906 Hall-effect

2 Pages

-

TT-420 Temperature Transmitters

2 Pages

-

Tachometers - HH100

2 Pages

-

Sensors - 906 Hall Effect

2 Pages

-

Electro-Sentry™

4 Pages

-

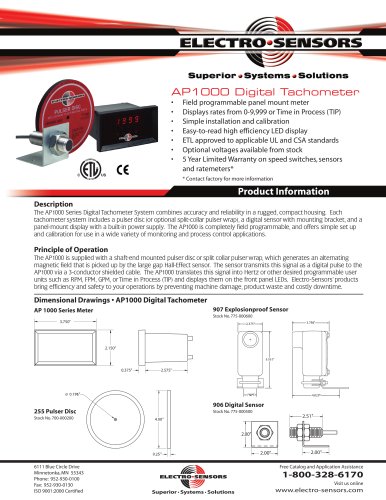

Tachometers - AP1000

2 Pages

-

SpeedTalker DN-BH

2 Pages

-

Signal Conditioners - SA420

2 Pages

-

Vibration Monitors - VS-1

2 Pages

-

Speed Switches - SS110

2 Pages