Catalog excerpts

GET OFF THE DOWNTIME ROLLER COASTER. Belt Misalignment Shaft Over/ Under Speed Bearing Failure Motor Overheating INDUSTRIAL ShAfT SPEED, VIBRATION, TEmPERATURE AND POSITION mONITORING

Open the catalog to page 1

: Scheduled Predictive Pre-emptive Maintenance Maintenance Repair Speed Switch System Using Shaft Speed ELECTRO SENSORS The Original Machine Monitoring Experts

Open the catalog to page 2

Why monitor your machinery? monitoring critical moving parts on any machine is a wise investment. With the proper devices, it’s relatively simple to recognize changes in shaft speed, vibration and bearing temperatures as indicators of potential failures and maintenance issues. In doing so, failures can be detected before they happen, allowing for proactive maintenance to be scheduled instead of a reactive response that forces machinery shutdown. Downtime is greatly reduced. Operational life is increased. material waste is controlled. And collateral damage and potential safety problems are...

Open the catalog to page 3

What are the benefits of using Shaft Speed Switches? Shaft Speed Switches provide many valuable direct and indirect benefits to any application in which they are applied. first and foremost, using Speed Switches allows equipment to have a longer life with less downtime because maintenance can be performed proactively and ahead of unexpected failures that can cause damage. This will greatly reduce your downtime, maintenance cost, and lower your material waste cost. And operational life is maximized without the risk of unexpected failures. In addition, Shaft Speed Switches can give you better...

Open the catalog to page 4

How to choose the right Shaft Speed Switch for your application. Whether you need detection of critical speed, direction of speed, one or multiple relay outputs, or speed to analog conversions, ElectroSensors has a Shaft Speed Switch that can do it. Also, whether your environment is hazardous, wet, or contains dust, dirt, oil, grease, severe vibration, electrical noise, extreme heat, or freezing cold, we have a rugged, robust system that can handle it. Electro-Sensors has a Shaft Speed Switch to monitor your application in any combination of these requirements and at almost any RPm range....

Open the catalog to page 5

A pump application utilizes the UDS 1000 Shaft Speed Switch with a 907XP Sensor and Pulser Wrap to detect reverse rotation of the pump shaft and prevent catastrophic damage to the pump shaft. SCP-Series Shaft Speed Switch features a dust-, water- and explosion-proof housing in this screw conveyor application. SG1000-Series Position Monitor accurately monitoring position on a slide gate.

Open the catalog to page 6

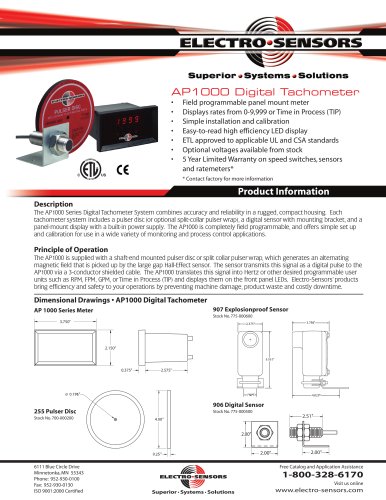

VS2 monitoring acceptable vibration levels on a vibratory conveyor. AP1000 Digital Tachometer with 906 Sensor and 255 Pulser Disc displaying rate on a web press. VS1 and TR400 Ratemeter System monitoring for critical shaft speed and over-vibration on a hammermill.

Open the catalog to page 7

LRB1000 DIN Rail mounted Shaft Speed Switch with 906 Sensor and Pulser Wrap detects overspeed, underspeed, or stoppage of fans, blowers and more. 906 Sensor and 255 Pulser Disc send shaft pulses to a PLC from a rotary air lock. Explosion-proof, NEMA 4X FB420 Shaft Speed Sensor and 255 Pulser Disc monitor for shaft slowdown or belt slippage on a bucket elevator.

Open the catalog to page 8

SA420 Signal Conditioner, 907XP Sensor and 255 Pulser Disc monitoring shaft speed and coal feed rate on a volumetric coal feeder. CT6000 Process Control Counter displays valve position communicated by the 907 XP Sensor and 255 Pulser Disc. Make sure there is free application and technical support. As the acknowledged experts in shaft speed monitoring, Electro-Sensors has a full staff of application experts to help you through every step of your application. from finding the perfect Shaft Speed Switch for your application, through getting it up and running, Electro-Sensors will be there to...

Open the catalog to page 9

What about other risks in shaft-driven equipment? Comprehensive monitoring solutions for rotating shaft systems components are available and easy to apply. Electro-Sensors offers a complete hazard monitoring system for applications with rotating shafts, belts and bearings, such as bucket elevators and beltdriven conveyors. The Electro-Sentry™ hazard monitoring System monitors the key elements of shaft speed, belt alignment and bearing temperature with a turnkey system, plus a Command Center™ touch screen for easy visual monitoring and fast alarm identification. Electro-Sentry™— complete...

Open the catalog to page 10

How to choose the best Speed Switch technology. The hall-Effect sensing technology used by Electro-Sensors offers several advantages over other methods. It allows for a large gap between the sensor and target (up to 1/4” ± 1/8”), which is necessary for applications where the shaft undergoes significant end play. This system is also very forgiving to vibration, electrical noise, grease, dust, dirt, moisture, and other elements commonly found in industrial facilities. We also offer EZ-mount Brackets Assemblies and stainless steel discguards to meet almost every application need. EZ-mount...

Open the catalog to page 11

In the most demanding industrial environments, we can monitor your machinery and be a valuable part of your proactive maintenance program. A leader in the speed monitoring industry for over 40 years, Electro-Sensors is committed to providing excellence in product and service for total customer satisfaction. With Speed Switches as our main focus, we provide you with products that meet or exceed the specifications of almost any application environment, including extreme conditions. Our complete, ready-to-install systems have been proven reliable by thousands of users worldwide....

Open the catalog to page 12All Electro-Sensors catalogs and technical brochures

-

HazardProTm

12 Pages

-

Brochure ELECTRO SENSORS

40 Pages

-

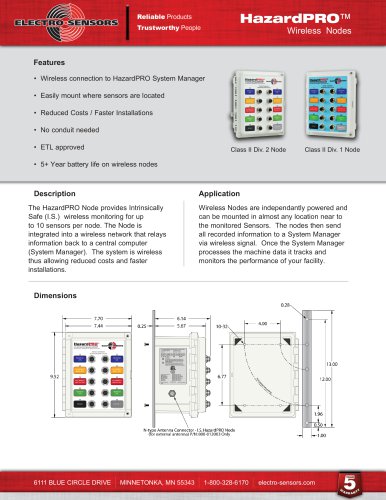

HAZARDPRO™ NODE

2 Pages

-

HAZARDPRO™ BEARING SENSOR

2 Pages

-

VTHP

2 Pages

-

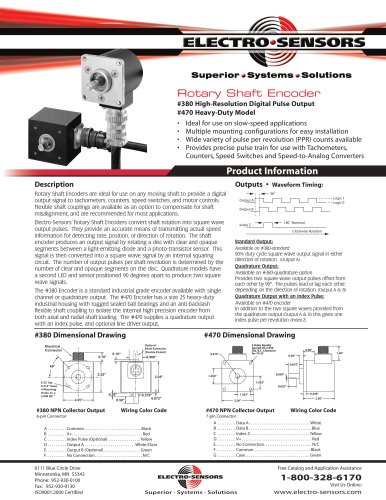

DIGITAL RING KITS

3 Pages

-

Accu-Tach & Accu-Dial

2 Pages

-

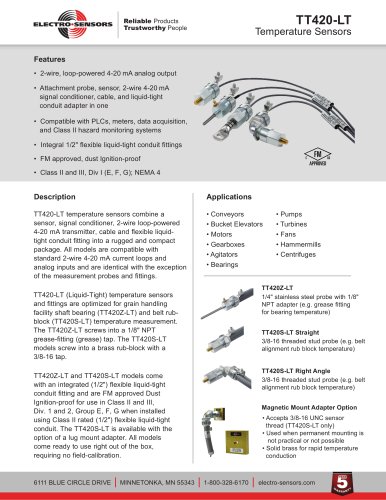

TT420-LT

2 Pages

-

TT420

2 Pages

-

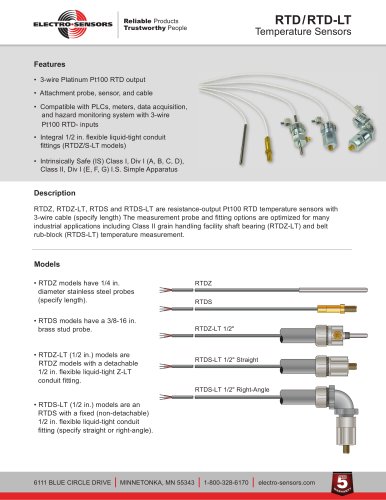

RTD/RTD-LT

2 Pages

-

PM500

2 Pages

-

SCP1000 / SCP2000

2 Pages

-

HH100 Hand-Held Tachometer

2 Pages

-

TR400

2 Pages

-

TR5000

2 Pages

-

SG1000A

2 Pages

-

SG1000B

2 Pages

-

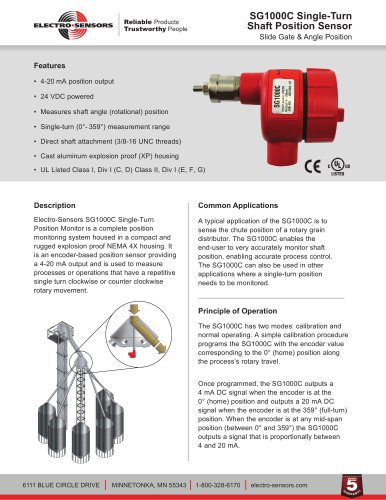

SG1000C

2 Pages

-

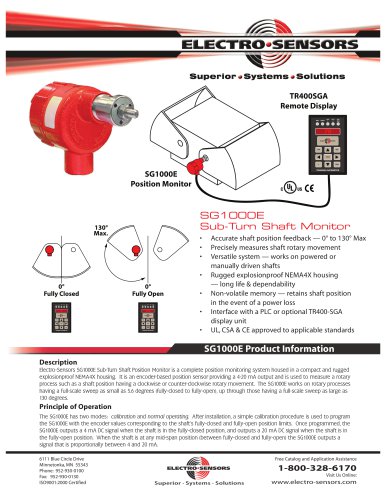

SG1000E

2 Pages

-

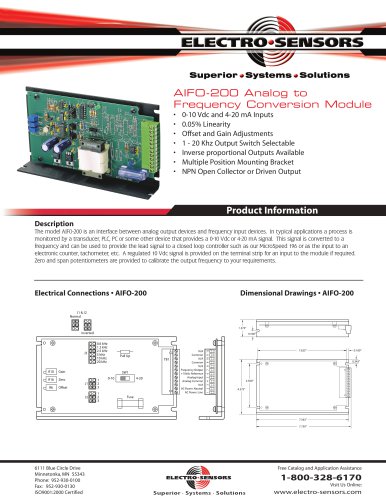

AIFO-200

2 Pages

-

MTS Series & SCU-200

2 Pages

-

VUM800

2 Pages

-

VS1/ VS2

2 Pages

-

ION Remote I/O

2 Pages

-

SpeedTalker-DN(BH) DeviceNet

2 Pages

-

SpeedTalker-DN(UI)

2 Pages

-

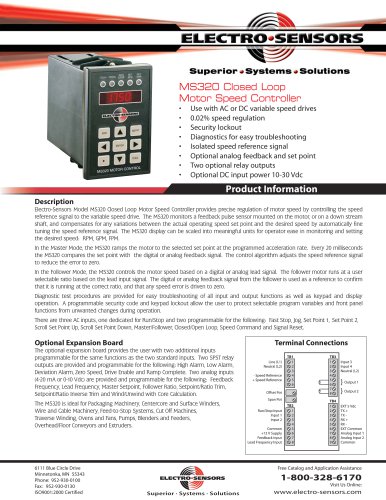

MS320

2 Pages

-

MS196

2 Pages

-

MS332

2 Pages

-

SpeedTalker-DN(XP) DeviceNet

2 Pages

-

SA420

2 Pages

-

LRB1000 / LRB2000

2 Pages

-

Stainless Steel Disc Guards

2 Pages

-

Product Brochure

28 Pages

-

ION Modbus RTU I/O Modules

1 Pages

-

ST420 Shaft Tachometer

2 Pages

-

Sensors - 907 XP Hall-effect

2 Pages

-

Sensors - 1101 Hall-effect

2 Pages

-

Sensors - 608-1 Proximity Sensor

2 Pages

-

Sensors - 906 Hall-effect

2 Pages

-

TT-420 Temperature Transmitters

2 Pages

-

Tachometers - HH100

2 Pages

-

Sensors - 906 Hall Effect

2 Pages

-

Electro-Sentry™

4 Pages

-

Tachometers - AP1000

2 Pages

-

SpeedTalker DN-BH

2 Pages

-

Signal Conditioners - SA420

2 Pages

-

Vibration Monitors - VS-1

2 Pages

-

Speed Switches - SS110

2 Pages