Website:

Electro-Sensors

Website:

Electro-Sensors

Catalog excerpts

MS332 Synchronous Controller Features: • • • • • • • • • Compatible with all variable-speed drives Keypad/display menus and features Setup, calibration and diagnostic utilities Special features including pulse per index measurement and averaging Master, ratio-follower, and index-follower modes Multiple set-points Switch-input functions NPN-output functions Serial Modbus communications R Description The MS332 is a powerful and versatile tool for building numerous closed-loop processes. Closed-loop control capabilities include speed and phase control, electronic line shaft/gearing, event synchronization, and bi-directional control. The MS332 accepts quadrature encoder signals and almost any type of index/event sensor signal. The controller also provides the encoder/sensor power, which makes the MS332 ideal for new or existing systems. The MS332 supplies an isolated 0 ±10 VDC speed reference signal to the drive, making it compatible with virtually any variable speed drive (AC, DC, or servo). Operating Modes Index Follower The MS332 automatically phases the feedback and lead event pulses to precisely synchronize events. Dissimilar encoders and shaft speeds work together without error. Feedback, lead, and event-pulse signals input to the MS332. Application Diagrams Superior · Systems · Solutions Event pulses are commonly generated by proximity and photoelectric sensors, although other sources may be used. The follower phase set-point may be entered or determined by advancing/retarding the set-point on-the-fly. Ratio Follower The MS332 achieves true electronic gearing by precisely setting follower ratio to master speed, resulting in zero cumulative error. Dissimilar encoders and shaft speeds work together without error. Feedback and lead signals input to the MS332. The user enters the follower/master speed ratio and may change it on-the-fly. Master The MS332 maintains the desired set-point speed. Feedback signal inputs to the MS332. The user may easily change the set point by entering the desired new value into the front panel keypad. Event Pulse “Optional” Event Pulse “Optional” MS332 Lead Motor Phase Offset Follower Motor Advance Retard Ratio Free Catalog and Application Assistance: 1-800-328-6170 ISO9001:2000 6111 Blue Circle Drive, Minnetonka, MN 55343 USA www.electro-sensors.com Superior · Systems · Solutions

Open the catalog to page 1

Electro-Sensors, Inc. MS332 Synchronous Controller Wiring Diagram MS332 TYPICAL ENCODER AND INDEX DEVICE WIRING LEAD ENCODER CABLE FEEDBACK ENCODER CABLE 6 +12 Vdc (C) 7 Fdbk Ch A 8 Fdbk Ch B 9 Fdbk index 10 MASTER CONTROLLED PROCESS Quadrature Encoder Quadrature Encoder M INDEX FOLLOWER CONTROLLED PROCESS FEEDBACK INDEX CABLE INDEX DEVICE TYPICAL DRIVE WIRING TB1 Variable Speed Drive Speed Reference Input Common Output to Motor Switch Input (drive enable, etc.) Common TYPICAL NPN OUTPUT WIRING Current limit Resistor DC Power Supply 300 Volts or Less (Ref to Ground C) (_) TYPICAL SWITCH...

Open the catalog to page 2All Electro-Sensors catalogs and technical brochures

-

HazardProTm

12 Pages

-

Brochure ELECTRO SENSORS

40 Pages

-

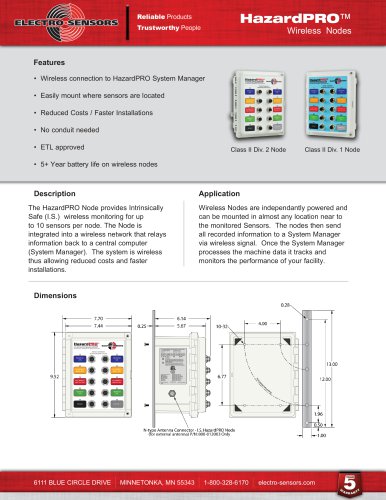

HAZARDPRO™ NODE

2 Pages

-

HAZARDPRO™ BEARING SENSOR

2 Pages

-

VTHP

2 Pages

-

DIGITAL RING KITS

3 Pages

-

Accu-Tach & Accu-Dial

2 Pages

-

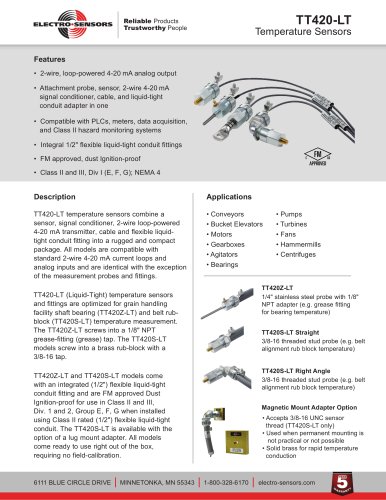

TT420-LT

2 Pages

-

TT420

2 Pages

-

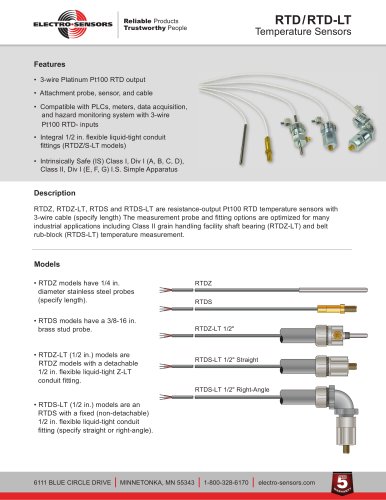

RTD/RTD-LT

2 Pages

-

PM500

2 Pages

-

SCP1000 / SCP2000

2 Pages

-

HH100 Hand-Held Tachometer

2 Pages

-

TR400

2 Pages

-

TR5000

2 Pages

-

SG1000A

2 Pages

-

SG1000B

2 Pages

-

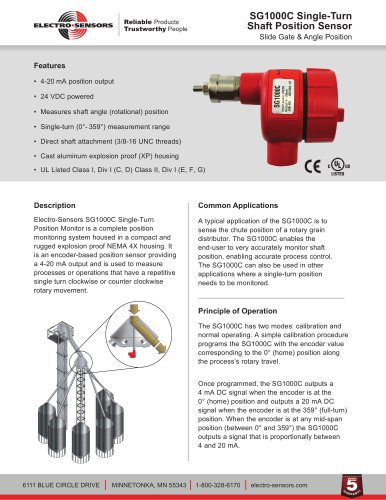

SG1000C

2 Pages

-

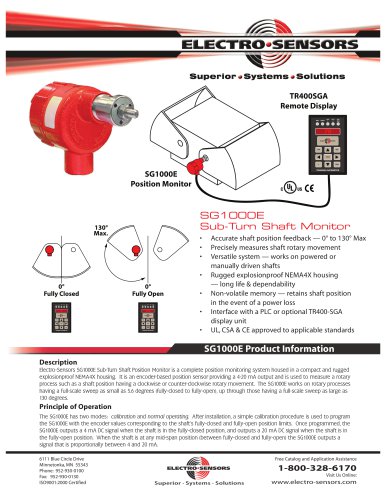

SG1000E

2 Pages

-

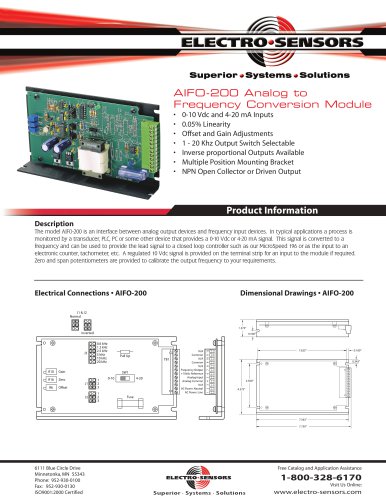

AIFO-200

2 Pages

-

MTS Series & SCU-200

2 Pages

-

VUM800

2 Pages

-

VS1/ VS2

2 Pages

-

ION Remote I/O

2 Pages

-

SpeedTalker-DN(BH) DeviceNet

2 Pages

-

SpeedTalker-DN(UI)

2 Pages

-

MS320

2 Pages

-

MS196

2 Pages

-

SpeedTalker-DN(XP) DeviceNet

2 Pages

-

SA420

2 Pages

-

LRB1000 / LRB2000

2 Pages

-

Stainless Steel Disc Guards

2 Pages

-

Shaft Speed Switch

12 Pages

-

Product Brochure

28 Pages

-

ION Modbus RTU I/O Modules

1 Pages

-

ST420 Shaft Tachometer

2 Pages

-

Sensors - 907 XP Hall-effect

2 Pages

-

Sensors - 1101 Hall-effect

2 Pages

-

Sensors - 608-1 Proximity Sensor

2 Pages

-

Sensors - 906 Hall-effect

2 Pages

-

TT-420 Temperature Transmitters

2 Pages

-

Tachometers - HH100

2 Pages

-

Sensors - 906 Hall Effect

2 Pages

-

Electro-Sentry™

4 Pages

-

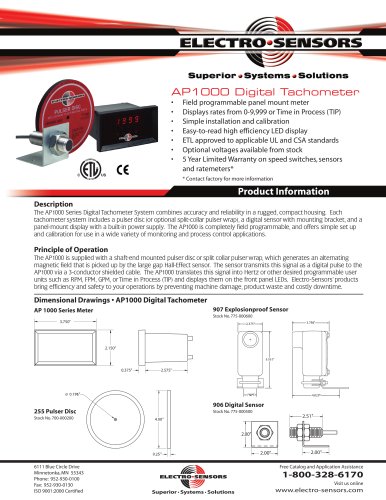

Tachometers - AP1000

2 Pages

-

SpeedTalker DN-BH

2 Pages

-

Signal Conditioners - SA420

2 Pages

-

Vibration Monitors - VS-1

2 Pages

-

Speed Switches - SS110

2 Pages