Catalog excerpts

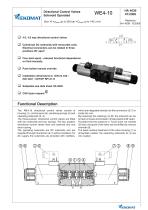

Directional Control Valves Solenoid Operated Size 10 · pmax up to 350 bar · Qmax up to 140 L/min 4/3, 4/2 way directional control valves Cylindrical DC solenoids with removable coils. Electrical connectors can be rotated in three positions 90° apart Four-land spool - reduced functional dependence on fluid viscosity Push button manual override Installation dimensions to DIN 24 340 / ISO 4401 / CETOP RP121-H Subplates see data sheet HA 0002 Functional Description The RPE4-10 directional control valves consist of WE4-10 housing (1), control spool (5), centering springs (4) and operating solenoids (2, 3). The three-position directional control valves are fitted with two solenoids and two springs. The two position directional control valves have one solenoid and one return spring. The operating solenoids are DC solenoids and are supplied through connectors (6, 7) without rectifiers. For AC supply the solenoids are provided with rectifiers, which are integrated directly into the connectors (6, 7) or inside the coil. By loosening the retaining nut (8), the solenoid can be turned on its axis and locked in three positions 90° apart. Provided that the pressure in T-port does not exceed (25 bar), the spool of the valve can be shifted by manual override (9). The basic surface treatment of the valve housing (1) is phosphate coated, the operating solenoids (2, 3) are zinc coated.

Open the catalog to page 1

Directional Control Valve Solenoid Operated Nominal size Number of operating positions two positions three positions Sensing of the end position no designation without s ensor S1 normally-open sensor to 50bar S2 normally-open sensor to 210bar S4 normally-closed sensor to 50bar Functional symbols see the table functional symbols Rated supply voltage of solenoids (at the coil terminals) 12 V DC / 3.17 A 24 V DC / 1.73 A 205 V DC / 0.20 A 230 V AC / 0.20 A / 50 (60) Hz 120V AC / 60Hz* Seals standard (NBR) Viton (FPM) Damping without damping nozzle throttle screw The AC coils correspond with E5...

Open the catalog to page 2

Technical Data Nominal size Maximum flow Maximum operating pressure at ports P, A, B Maximum operating pressure at port T Pressure drop Hydraulic fluid Fluid temperature range (NBR/Viton) Viscosity range Maximum degree of fluid contamination Hydraulic oils of power classes (HL, HLP) to DIN 51524 Maximum allowable voltage variation Maximum switching frequency Duty cycle Service life Weight - valve with 1 solenoid - valve with 2 solenoids Mounting position Functional Symbols

Open the catalog to page 3

Operating limits for maximum hydraulic power transferred by the directional valve. For respective spool type - see functional symbols. The power curves hold true for symmetrical valve flows (e.g. flows in directions P-A and B-T are identical). In case of an asymmetric flow, the power curves can lie substantially lower. In such cases we highly recommend to consult the respective power curve with the valve manufacture. Pressure drop Dp related to flow rate.

Open the catalog to page 4

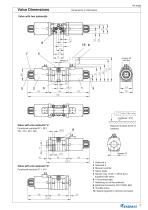

Valve Dimensions Valve with two solenoids Valve with one solenoid "a" Functional symbols R11, R21, Y51, C51, Z51, H51, Required surface finish of interface. Valve with one solenoid "b" Functional symbols C11, H11 Solenoid a Solenoid b Manual override Name plate Square ring 12,42 x 1,68 (5 pcs.) supplied with valve 6 4 mounting holes 7 Retaining nut of the solenoid 8 Electrical connector, EN 175301-803 9 Throttle screw 10 Space reguired to remove connector

Open the catalog to page 5

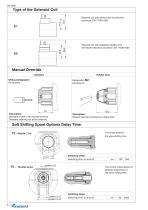

Solenoid coil with terminal for the electrical connector, EN 175301-803 Solenoid coil with integrated rectifier and terminalfor electrical connector, EN 175301-803 Type of the Solenoid Coil Manual Override Standard Rubber boot Without designation Dimensions 33 Description: Standard model of the manual override. Standard retaining nut of the solenoid. 50,5 Description: Manual override protected by rubber boot. Soft Shifting Spool Options Delay Time The orifice extends the valve shifting time. Switching times Switching time, on and off Throttle Screw The control orifice allows for stepless...

Open the catalog to page 6

Spool Ship Position Sensor S1, S2 - Circuit diagram of the normally-open sensor The proximity sensor transforms the spool position into an electrical step signal. It can be used with directional control valves with one or two solenoids. normally-closed sensor Technical Data of the Sensor Rated power supply voltage Power supply voltage range Rated current Enclosure type of sensor to EN 60529 Max. operating pressure Switching frequency Ambient temperature range Technical Data of the Connector Power supply voltage range Ambient temperature range Indication yellow LED Two-Position Directional...

Open the catalog to page 7

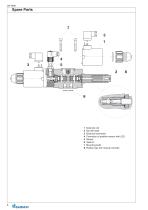

Spare Parts 4 Connector of position sensor with LED 8 Rubber cap with manual override

Open the catalog to page 8

HA 4039 Solenoid coil Type of the coil Type designation of the coil voltage Solenoid retaining nut with seal Type of the nut Seal ring Ordering number Rubber cap with manual override Connector of position sensor Type designation Ordering number connector of position sensor with LED normally-open sensor normally-open sensor normally-clsed sensor Square ring Ordering number Mounting bolts Dimensions Tightening torque Ordering number Soft Shift Conversion Kit Electrical connector, EN 175301-803 Type designation Ordering number Connector B (black) Connector A (grey) Connector B (black)...

Open the catalog to page 9

Preffered Types Type Ordering number Ordering number Caution! In the case of directional valves with two solenoids, any of the solenoids may be energized, but only after switching off the other. Directional valves with other functional symbols as those shown in the table, please consult with the manufacturer. The packing foil is recyclable. The protective plate can be returned to manufacturer. Mounting bolts M6 x 40 DIN 912-10.9 or studs must be ordered separately. The technical information regarding the product presented in this catalogue is for descriptive purposes only. It should not be...

Open the catalog to page 10All EKOMAT GmbH & Co. KG catalogs and technical brochures

-

CETOP control valves

1 Pages

-

COMPACT UNITS

1 Pages

-

RADIAL PISTON FLOW DIVIDER

1 Pages

-

AS A SYSTEM SOLUTION

1 Pages

-

EKOMAT Flow divider designs

38 Pages

-

Ekomat WE3-06

10 Pages

-

Ekomat WE3-04

8 Pages

-

Directional Control Valves

8 Pages

-

Gear Flow Divider

12 Pages

-

Radialpiston Flowdivider

24 Pages

-

Product Overview

12 Pages