Catalog excerpts

MARATHON ALLROUND ELTOLA energy chains and energy chain systems in steel and plastics Order infos Design guidelines

Open the catalog to page 1

1970and since 2022 a member of HELUKABEL GmbH. From the founding product energy pipe is formed today a wide EKD SYSTEMS is manufacturer of energy chains since with cables, connectors and mounting kits for every application. The service spectrum ranges from the selection and design of appropriate energy chains, electrical In addition to standardizised series products in steel and plastics special products are a priority of the ekd product range, which are designed and made of materials in Order infos up to plug in speciality products and tailor-made solutions provides the standard of energy...

Open the catalog to page 2

Energy chain systems | Electrical cables | Hoses part numbers Strain reliefs Order informations part numbers part numbers SLS with foam stay SLP with plastic divider Pz SLR with pipe- / rollstays part numbers gliding applications Energy chain systems System Marathon System Allround System Eltola System Reintec PLP with plastic divider Pz PLS with foam stay Safety instructions MARATHON ALLROUND ELTOLA

Open the catalog to page 3

If several lines are to be laid in one chamber, the chamber dimensions have to be restricted so that they maintain their relative positions. Even multi-layer arrangements of flat cables have always to be seperated with horizontal dividers. When using pressure hose a change in length has to be taken into account through additional clearance in the chain bow (radius), which can be achieved by a corresponding chain height (a). The distribution of the energy chain cross-section should be symmetrical in order to ensure an uniform load. In addition heavy lines are laid out close to the links to...

Open the catalog to page 4

DESIGN GUIDELINES In standard applications the fixed connector of the energy chain is arranged in the middle of the travel distance. The moving connector moves horizontally over the fixed connector between the end positions of the travel. The required length of the energy chain between the first and the last pivoting link is then determined as follows: Order infos If the fixed connector is not in the middle of the travel, the energy chain has to be extended by a displacement of x: L length of the energy chain LV length of travel R bending radius of the energy chain Design guidelines Energy...

Open the catalog to page 5

The sag is due to the additional load and the weight of the energy chain. Due to the significantly lower elongation of steel (0.2% linear elongation) compared to plastics the permissible sag of the steel chains is limited lower than for plastic energy chains. On the other hand, the effect on plastic energy chains of a long-term static load with a long unsupported length of the upper strand chains will increase the sag (creeping of plastics). Elevated temperatures and humidity increases this effect. The sag of energy chains is also increased by use-wear. sag The maximum allowable sag can...

Open the catalog to page 6

DESIGN GUIDELINES Order infos This type is mainly used with plastic energy chain applications. As with the use of support rolls the maximum travel can be increased up to four times the free carrying length. Because of the larger permissible sagging, support rolls are not suitable for plastic energy chains. Design guidelines Raised trough Support carriage For long travel distances and high additional loads support carriages can be used with reverse travelling energy chains. The side-mounted support rolls carry the energy chain and move the support carriage. The energy chains now only face...

Open the catalog to page 7

multiaxial (m) In the multiaxial arrangement is a vertical and horizontal motion of the driver along the x-axis (travel direction) and one or more movement in the y- or z-direction. While running in the y-direction may be done by any conventional energy chain, the movements in the z-direction require the energy chain system ALLROUND. Content Design guidelines Order infos In the normal arrangement the fixed connector is usually on the first link in the lower strand in the middle of the travel. The moving end connector is moving the chain in a straight line lengthwise at a height of 2R+c over...

Open the catalog to page 8

Design guidelines The arrangement of two or more energy chains with different bending radii or even different energy chains makes sense when using a variety of cables and hoses together. The energy chains are moved together by a common driver. Order infos Opposite running means two energy chains running in one line synchronuosly or independent of each other. It is a further possibility to raise the number of moved lines without increasing the necessary space. gliding arrangement (l) If the free carrying length is exceeded, the energy chain changes into a gliding state. In this arrangement,...

Open the catalog to page 9

driving apart (a) With energy chains moving apart the calculation of the energy chain length does not follow the usual pattern, but be adapted to the individual requirements of the application. The circular motion is a special form of chain movement. For circle movement a part of the energy chain has to be manufactured with an opposite bending radius R2. The outer radius R3 is derived from the link height, the bending radius of the energy chain R1 and the opposite radius R2. Design guidelines Energy chains are arranged horizontally lying on their side, for example, if the space does not...

Open the catalog to page 10

Order infos Design guidelines For laying in energy chains only highly flexible cables with permissible bending radii and sufficient dynamic capacity suitable. The cables have to be laid twist free to move freely lengthwise. Cable on a reel should be unrolled in the reverse winding direction and placed in the extended state in the energy chain. For intermediate storage the lines are ideally laid out straight. The material relaxation occurs in this case facilitates a twist-free installation. The distribution of the chain interior must prevent mutual interference between the wires with...

Open the catalog to page 11

The aluminum anchor profile is used to mount various strain relief elements. Both the distance to the energy chain as well as the positioning of the strain relief elements can be easilz designed. The length of the anchor profile and the drilling dimensions are determinded by the dimensions of the energy chain. strain relief stay ZLS The strain relief stay was developed for anchoring the blue ribbon and the cable anchor. The design of the strain relief stay is closely based on the plastic divider (PZ). It is installed laterally into the anchor profile or a commercially available C-profile...

Open the catalog to page 12All EKD Systems GmbH catalogs and technical brochures

-

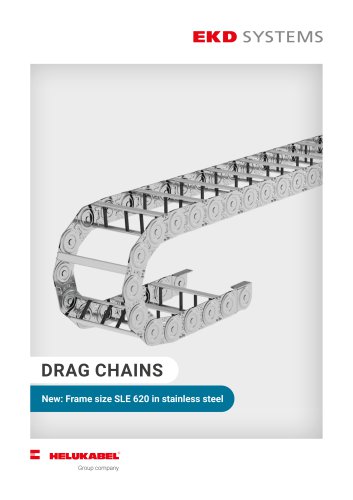

DRAG CHAINS

6 Pages

-

PFR

2 Pages

-

SFK

2 Pages

-

GKA

6 Pages

-

PKK

18 Pages

-

Kolibri

30 Pages

-

PLE

14 Pages

-

SLE

18 Pages

-

Main Catalogue

126 Pages