Website:

EIDE

Website:

EIDE

Catalog excerpts

TECHNICAL SHEET CENTRIFUGAL SAFETY BRAKES Type EC/2B5 Description EC centrifugal brakes control the rate of descent when this is made without a voluntary or accidental actuation of the engine. Its working principle is the centrifugal force. This force acts on masses that rub a static drum. ASSEMBLY EXAMPLES As the centrifugal force is an exponential function of the speed, a balance between load power during the descent and braking power always occurs. The load will be maintained by balancing speed up to the stop or until a parking brake acts. Consequently, centrifugal brakes are not locking brakes but retaining brakes. The best results are obtained in fast axes. They are usually applied between the motor and gearbox. And by its tare, these only slow when the rated engine speed is exceeded. Centrifugal brake The EC centrifugal brakes consist essentially of a central core that rotates integrally with the motor shaft. On its periphery a series of masses are distributed among sectors. These masses are carried by the guides. The masses can move radially along its guide. The force of the wrap springs is opposed to this motion. The masses are externally coated by a friction material which is free of asbestos. The whole system is mounted inside a drum or a concentric flange attached directly to the reducer unit housing. The flange serves as engine mount. Centrifugal brakes allow a controlled descent in the absence of motorization and in case of failure of the holding brake. Centrifugal brakes do not allow uncontrolled acceleration of the load. Thus, the expected accident only becomes an incident. Obviously, the brake and the centrifugal brake can’t prevent an accident if the failure occurs on the reducer or any element that is in position after them. If the centrifugal brake is mounted by an independent transmission, it will behave as a final safety, since it will act independently if the parking brake or the reducer is disabled by a fault or a break. Performance Engine and brake core rotating at normal speed In these circumstances, the brake springs are rated so that action compensates centrifugal forces of the masses. The masses remain fixed to the core and brake behaves as a completely passive element. Engine and brake core rotating at a speed higher than the normal speed If for any reason the speed of rotation of the core exceeds the nominal, the masses overcome the springs’ action, rubbing against the inner wall of the fixed drum and producing friction against the brake. Electromagnetic, pneumatic brakes and clutches Mechanical safety brakes · Centrifugal brakes Flexible couplings · Torque limiters · Special u

Open the catalog to page 1

CENTRIFUGAL SAFETY BRAKES Type EC/2B5 Dimensions Sizes EC-201 EC-401 EC-80 Centrifugal brakes’ applications by independent transmission The multiplier and the centrifugal brake act as followers without providing any effort. Only when the increase ofspeed exceeds tare brake, i t will begin to act by controlling the rate of descent, similarly as in the previous case. These sketches show a rack and pinion system. Its effect is the same for cable drum systems. Centrifugal brake Blocking brake

Open the catalog to page 2All EIDE catalogs and technical brochures

-

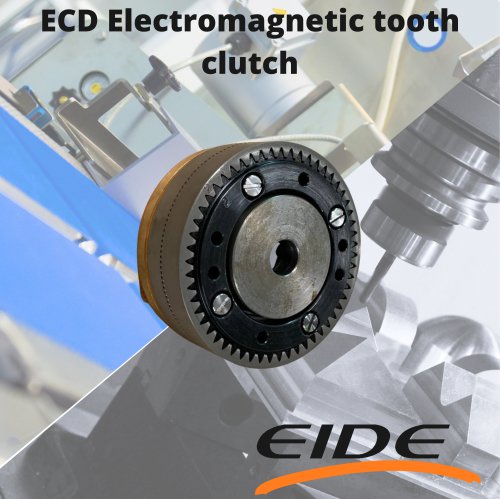

ECD

3 Pages

-

FNB

3 Pages

-

FPC

9 Pages

-

SER

4 Pages

-

SEE

4 Pages

-

SED

4 Pages

-

NE

4 Pages

-

FNAM & FNA

4 Pages

-

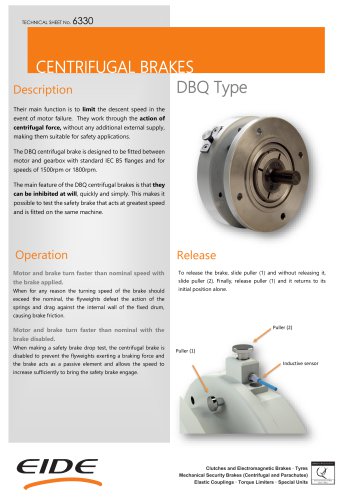

DBQ

5 Pages

-

Escobillas y Portaescobillas

1 Pages

-

LPB

2 Pages

-

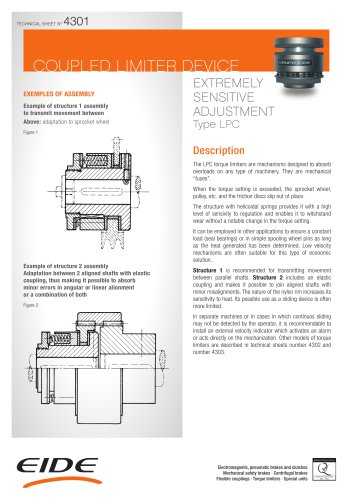

LPC

2 Pages

-

NEF

2 Pages

-

GEF

2 Pages

-

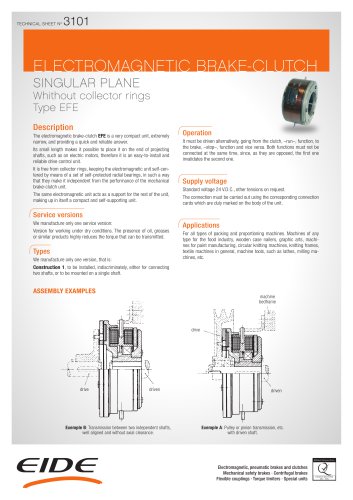

EFE

2 Pages

-

FNB

1 Pages

-

DBQ

2 Pages

-

FIP

2 Pages

-

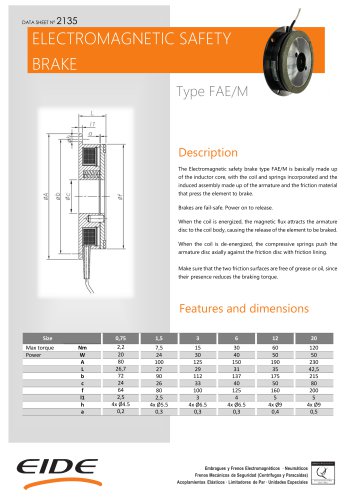

FAE/M

1 Pages

-

FNH

1 Pages

-

FZ

2 Pages

-

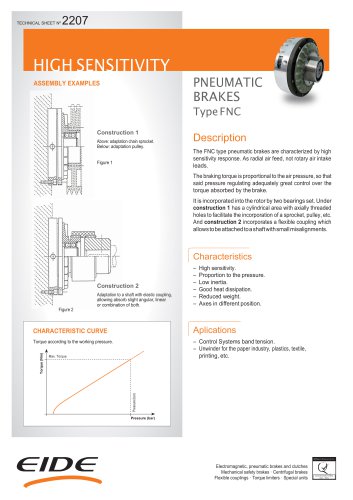

FNC

2 Pages

-

FAE

2 Pages

-

FPC

2 Pages

-

ECD

2 Pages

-

SED

2 Pages

-

SER

2 Pages

-

SEE

2 Pages

-

EN

1 Pages

-

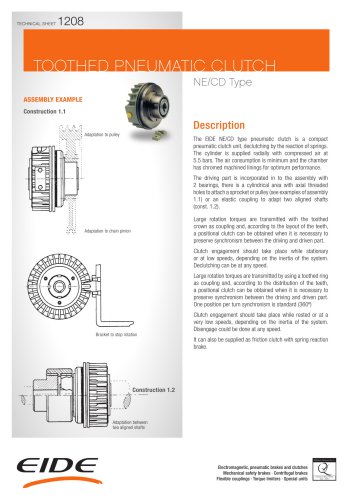

NE/CD

2 Pages

-

NE

2 Pages

-

ENP

2 Pages