Catalog excerpts

Main Catalogue Ballscrews Leadscrews A company of the Festo Group

Open the catalog to page 1

Eichenberger Gewinde AG Content Your partner for thread drive solutions – 100% Swiss-made Eichenberger thread drives Range summary ¡¡ Individual ¡¡ Standard tailor-made thread drives range overview: Thread drive types and their characteristics Eichenberger ballscrews Carry ballscrews (KGT) ¡¡ Design features / Production / Handling fundamentals for ballscrews Eichenberger leadscrews Speedy high-helix leadscrews (SGS) Cold-rolled thread drives for every requirement Eichenberger Gewinde AG has been supplying customers all Your tailor-made thread drive over the world with “100% Swiss-made”...

Open the catalog to page 2

Eichenberger thread drives Individual tailor-made thread drives Examples of customer-specific and application-specific solutions specific flange industry (building electric motors) screw diameter, special nut, ball recirculation made of high-temperature technopolymer Carry 8 × 2.5 made of corrosion-resistant steel industry (towed array sonar) nut with direct linear slide connection screw with extremely large, continuous bore hole Your revolutionary idea – our tailor-made solutions Any nut shape Innovative solutions often require special, application-specific nut shapes – sometimes the nut...

Open the catalog to page 3

Eichenberger thread drives Standard range overview Thread drive types and their characteristics Cold-rolled precision The manufacturing core competency of Eichenberger Gewinde AG is thread rolling. That is why the thread profiles of Eichen- Eichenberger ballscrews are characterised by: Eichenberger leadscrews are characterised by: berger screws are exclusively made using this highly precise process. Thread rolling describes the cold-forming process of the surface load ratings, and are therefore suitable for high static of round components. A thread is created by deforming a part between two...

Open the catalog to page 4

Carry ballscrews - design features Carry Nut types (shapes) Ball return systems _____ Design features End cap ball returns Type ...E / ...F I I ■ also for over-square pitches (p ^ d0) ■ wipers firmly integrated into end caps ■ made of high-performance technopolymer ■ cost-effective Tube ball return, fully integrated into nut body Type ...R I*"-* ■ for heavy loads ■ can also be used in high temperatures ■ space-saving in length Carry screws are made using the highly economical cold-rolling process, offering - at a significant price advantage - precision that has so far only been achieved...

Open the catalog to page 5

Eichenberger ballscrews Assembling of ballscrew units Production lengths In general, Eichenberger screws are produced as threaded rods Ballscrews are precision parts and must be protected from shock, Production / Handling / Lubrication dirt or moisture when transported or stored. Please do not unpack until ready for use. Please check for cleanness when mounting the ballscrew. Dirt or foreign matter on the ball race – especially inside the nut – may Ballscrew ends are without any machining cut by grinding cause increased wear and premature failure. Remove transport lock (O-ring) on one side....

Open the catalog to page 6

Eichenberger ballscrews Calculations at dynamic load The following are the relevant calculations which underlie screw Critical rotational speed nper design and safe operation. Design fundamentals Nominal service life L10 or L h Permissible rotational speeds must differ substantially from the For detailed information on ballscrew design, please refer to d2 nper = KD · 106 · ––– · Sn [min-1] la2 nper = permissible rotational speed [min-1] «Suitability test» rotational speed characteristics L10 = service life in revolutions [R] as a function of bearing configuration d2 = core screw diameter...

Open the catalog to page 7

Eichenberger ballscrews Calculations at dynamic load (continued) Efficiency η (theoretical) Average rotational speed nm at constant load Fconst and variable rotational speeds n1…n depends upon the type of power transmission depends upon the type of power transmission 1: torque ➞ linear movement 2: axial force ➞ torque Cstat = static load rate [N] fs normal operation: 1… 2 [–] ➞ shock load: 2 … 3 [–] ➞ Permissible maximum load Fper 1: torque ➞ linear movement Calculations at static load 2: axial force ➞ torque Ma = input torque [Nm], case 1 Me = output torque [Nm], case 2 Permissible...

Open the catalog to page 8

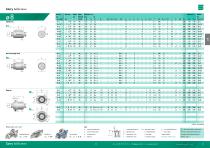

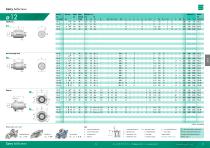

Eichenberger ballscrews Order system - Carry ballscrews Dimension map - Carry standard range Carry Example for complete Carry ballscrew Type of thread drive _ Nominal size (d0 x p) [mm] Nut type: ■ Shape for nut only ZY = cylindrical nut type ZY... FG = nut with mounting thread type FG. FB = flange nut type FB... FA = flange nut type FA. MS = special design according to drawing ■ Ball return system (assignment to nut shapes acc. dimensional charts) I = single-thread ball return type .I R = tube ball return type .R E = end cap ball return type .E F = end cap ball return type .F...

Open the catalog to page 9

Carry ballscrews Ball return Relative Right-/ cost left-hand Screw thread d1 Nut with mounting thread Ball return systems (details › page 9) d0 = nominal screw diameter [mm] i = number of ball circulations [–]

Open the catalog to page 10

Carry ballscrews Ball return Relative Right-/ cost left-hand Screw thread d1 Nut with mounting thread

Open the catalog to page 11

Carry ballscrews Relative Right-/ cost Type left-hand Screw thread d1 Nut with mounting thread Ln L2

Open the catalog to page 12

Nominal size Ball return Cdyn Cstat nominal screw diameter [mm] outer screw diameter [mm] core diameter [mm] pitch [mm] i = number of ball circulations [-] DW = ball diameter [mm] B = pin wrench hole * [mm] S = lubrication hole * [mm] wipers (details > page 9) K = technopolymer wipers B = brush wipers F = felt rings (on request) T = max. standard backlash [mm] * position not defined Special designs available on request > CAD data > www.gewinde.ch A When selecting a ballscrew, always observe the maximum rotational speed dependent on the system-specific rotational speed...

Open the catalog to page 13Archived catalogs

-

Jubiläumsbroschüre 60 Jahre EAG

20 Pages

-

Rondo round thread lead screws

12 Pages

-

Speedy high-helix lead screws

29 Pages

-

Carry ball screws

41 Pages