Catalog excerpts

Neumo Ehrenberg Group Automated ©rbital OTeldin

Open the catalog to page 1

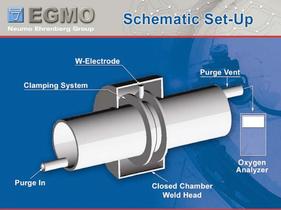

Clamping System Closed Chamber Weld Head

Open the catalog to page 2

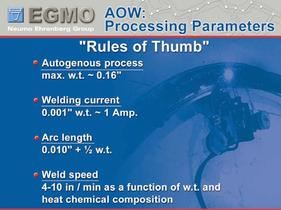

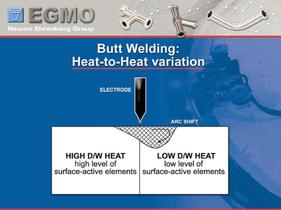

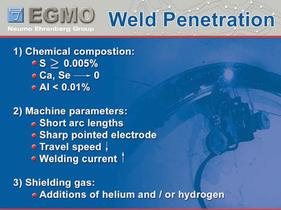

heat chemical composition

Open the catalog to page 3

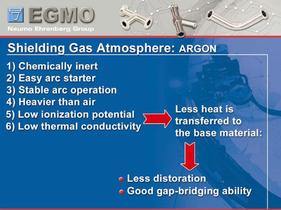

Shielding Gas Atmosphere: ARGON 5) Low ionization potential 5-\ ^ess hea 6) Low thermal conductivity L-/ ferr • Good gap-bridging ability

Open the catalog to page 4

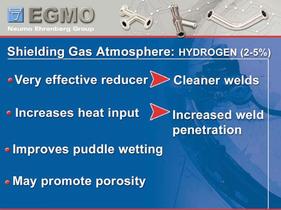

Shielding Gas Atmosphere: HYDROGEN (2-5% "Very effective reducer)^> Cleaner welds • Increases heat input 2> Increased weld Improves puddle wetting

Open the catalog to page 5

Butt Welding: Heat-to-Heat variation surface-active elements surface-active elements

Open the catalog to page 7

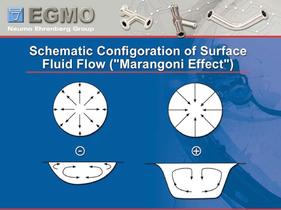

Schematic Configoration of Surface Fluid Flow ("Marangoni Effect")

Open the catalog to page 8

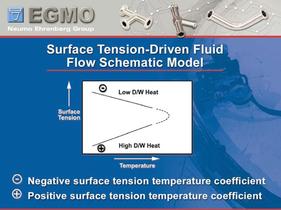

Surface Tension-Driven Fluid Flow Schematic Model © Negative surface tension temperature coefficien ® Positive surface tension temperature coefficient

Open the catalog to page 9

Sharp pointed electrode Additions of helium and / or hydrogen

Open the catalog to page 10

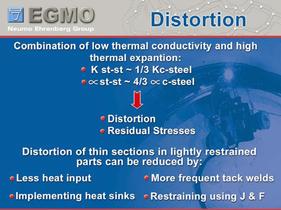

Combination of low thermal conductivity and high thermal expantion: • Residual Stresses Distortion of thin sections in lightly restrai Less heat input r More frequent tack welds - Implementing heat sinks Restraining using J & F

Open the catalog to page 11

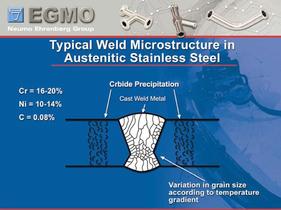

Typical Weld Microstructure in Austenitic Stainless Steel Crbide Precipitation Cast Weld Metal ariation in grain size

Open the catalog to page 15

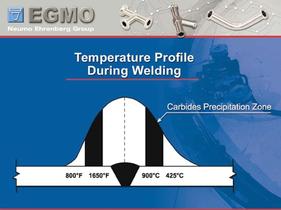

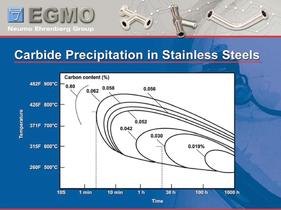

Temperature ProfiI During Welding Carbides Precipitation

Open the catalog to page 16

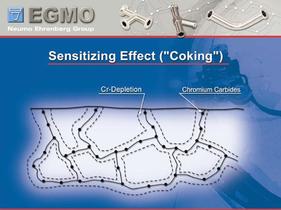

Sensitizing Effect ("Coking") Chromium Carbides

Open the catalog to page 17

Carbide Precipitation in Stainless Steels

Open the catalog to page 18

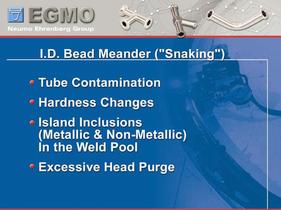

I.D. Bead Meander ("Snaking") Tube Contamination Hardness Changes Island Inclusions (Metallic & Non-Metallic) Excessive Head Purge

Open the catalog to page 20

• Organic / Hydrocarbon Residues Contamination (Oil, Grease, Paint, Etc.) r Excessive Moisture or Condensation Sources Promoting Porosity in Welds

Open the catalog to page 21

r Lower cost for machined parts. Inclusion Rating : «■ "Pits", "Stringers", "Pin-Holes" after passivation Resetting of weld parameters. Solidification Temperature Range Increased segregation in weld. Rouoher weld bead surface.

Open the catalog to page 22

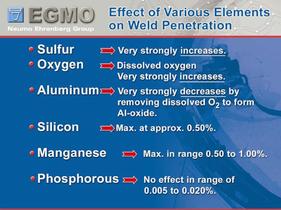

(?. c) Effect of Various Elements OJns^ on Weld Penetration • Sulfur s=> Very strongly increases. •Oxygen s=> Dissolved oxygen -^^B Very strongly increases. m r Aluminums Very strongly decreases by removing dissolved 02 to form r Silicon s=>Max. at approx. 0.50%. PhOSphorOUS No effect in range of

Open the catalog to page 23All EGMO LTD. catalogs and technical brochures

-

TMX Control Head

2 Pages

-

ESV CATALOG

4 Pages

-

MAXCLEAN

2 Pages

-

PVE LEAFLET

2 Pages

-

TWISTMAX CATALOG

17 Pages

-

SOLAR CATALOG

2 Pages

-

SCIMAX CATALOG

36 Pages

-

MAXPURE CATALOG

52 Pages

-

EGMO GENERAL LEAFLET

2 Pages

-

Mobile CIP

8 Pages

-

Butterfly valve

12 Pages

-

Sanitary Equipment Line

51 Pages

-

CF Flanges

36 Pages

-

ASA Fanges

16 Pages

-

ISO Fanges

16 Pages

-

Weld Fittings

16 Pages

-

Surface characterizations

12 Pages

-

Semi-Conductor industry

23 Pages

-

stainless steel

13 Pages

-

Corrosion in stainless steel

8 Pages

-

AL-6XN

2 Pages

-

880 Elbow

2 Pages

-

ASME BPE

11 Pages

-

Flanges

20 Pages

-

Vessels & Reactors

6 Pages

-

Sampling Valves

4 Pages

-

Single Seat

2 Pages

-

Butterfly & Ball - Midi

3 Pages

-

Butterfly & Ball - Mini

4 Pages