Catalog excerpts

EFD Induction The process, the products and the people. And how they are boosting industrial productivity. in amazing ways.

Open the catalog to page 1

Putting the smarter heat to smarter use. What this brochure is about. Meet the family. An overview of EFD Induction products. Faster. Better. Cheaper. A survey of three key benefits of induction heating. 907.5°C in 3.4 seconds. Time and again. And again. How induction heating works—and how it is superior to alternative technologies. In the heat business, the hardest part can be to stay cool. An introduction to EFD Induction services—what they are and how you benefit. “I’ll drive over right away.” EFD Induction in the real world—a case story from our files. A passion for heat. The EFD...

Open the catalog to page 2

Putting the smarter heat to smarter use. Welcome to EFD Induction. In the following pages you’ll read how induction heating is superior to alternative heating technologies. You’ll read how induction heating, because it’s faster than these alternatives, increases throughput. You’ll read how induction heating improves—and maintains—the quality of whatever it is you make, mend or process. And you’ll read how induction heating achieves the above while at the same time cutting costs. Just as important, you’ll read that we lead the world in finding new, exciting applications for induction...

Open the catalog to page 4

Faster. Better. Cheaper. The technical features of induction heating deliver three key benefits: improved throughput, better and consistent quality, reduced costs. Throughput Integrating induction heating into the production line improves production efficiency. You cut lead times, and speed up throughput. The heating process itself is faster than with open-flame and oven alternatives. Accurate repeatability means you get to be faster because you get it right the first time. Quality Quality improves because you can apply pre-set temperatures to pre-set parts of individual workpieces. And...

Open the catalog to page 5

FA S T E R – T H R O U G H P U T Ease of integration into production line Ramp-up time BETTER – QUALITY Heat pattern control Temperature level accuracy Ramp-up time control Dwell-time accuracy Repeatability CHEAPER – COST Yield Energy The scores used in this table are approximations only, designed as a general guide. The performance rating of the three heating methods can vary from case to case, depending on the application involved, workpiece characteristics, operator skills, etc.

Open the catalog to page 6

907.5°C in 3.4 seconds. Time and again. And again. Induction heating has numerous advantages over alternative technologies: Quick The produced heat from a frequency converter is instant. It takes less than one second to achieve a uniform surface temperature of 1,000°C on small metal components. Accurate Just the right temperature is delivered, just where it’s needed to individual workpieces. And because of the range of frequencies available, to just the right depth. Heat distribution is precise, too. We can customize induction coils to suit practically any shape or size of workpiece....

Open the catalog to page 7

Some amazing facts about induction heating. • An EFD Induction frequency converter with an output power of 100 kW can harden a 60 mm diameter shaft to a depth of 2 mm (800°C at 2 mm) with a feeding speed of 1 m per minute. • Using one of our mobile converters, you can heat 1 kg of steel from 20°C to 800°C in five seconds flat. That’s a speed-of-temperature increase of 160°C per second. • Induction heating is ten times more efficient than conventional ovens at curing the adhesives in automobile hoods. To cure one hood normally requires 220 kWs. As induction heating uses 340 kWs from the...

Open the catalog to page 8

Apart from our superior applications knowledge, equipment technology, coils capability, materials know-how and local presence, we’re pretty much like any other induction heating company. What makes EFD Induction special? Applications knowledge To date, EFD Induction has more than 9,500 installations in 75 countries. A large number are customized heating solutions—unique installations for specific production needs. This experience has given us unrivaled knowledge of applications as diverse as annealing, bonding, brazing, curing, forging, shrink-fitting, hardening, straightening, tempering,...

Open the catalog to page 9

Materials analysis at an EFD Induction research lab. This photograph shows the microstructure of alloyed steel C35, grain size ASTM6.

Open the catalog to page 10

The differences are obvious. What about the similarities? A can of peaches, a cruise liner’s hull, a tub of yogurt, power station turbines, cables under the ground, pipelines under the waves, and countless trains, planes and automobiles. What unites these different products is that induction heating is used to make them, maintain them, repair them and recycle them. (In case the yogurt tub intrigues you, induction heating attaches the foil lid to the plastic container. As for canned peaches, induction heating helps coat the tin on the can’s inside so that conserved foods remain untainted.)...

Open the catalog to page 11

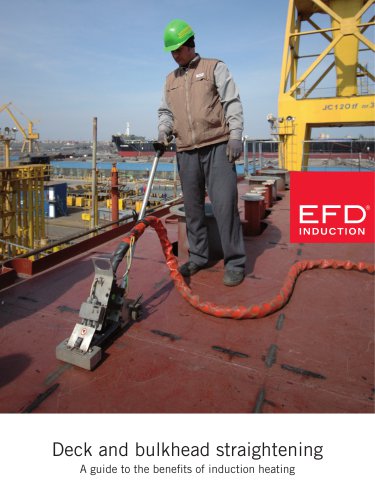

Heat treatment and pre/post heating. Bonding and joint brazing. Brazing of compressor parts. Bonding of fridge bodies. Paint curing. Tube welding. Hardening and tempering of transmission and engine parts (shafts, valves, etc.). Straightening during repairs. Brazing and soldering of brass parts. Hardening and tempering of engine and transmission parts. Curing of paint and brake-disc coatings. Bonding of body parts. Tube welding of exhaust pipes. Brazing of components. Magnet bonding in electric motors. Disassembly and shrink-fitting of wheel rings and bearing rings. Brazing of copper...

Open the catalog to page 12

Meet the family. Whatever your heating needs, it is almost certain EFD Induction has the equipment to meet them. And in the unlikely event we don’t, we can sit down with you and devise your own customized induction heating solution. This claim is backed by our range of equipment—and our decades of experience in the induction heating business. EFD Induction products range from standard heat sources, through customized solutions to complete manufacturing processes. With EFD Induction you also gain the support of our experts in power electronics, metallurgy and processcontrol software. Not to...

Open the catalog to page 13All EFD Induction Group catalogs and technical brochures

-

HARDLINE CP 600

2 Pages

-

Crankshaft hardening

4 Pages

-

Hardline CIHM-C

2 Pages

-

Coating Removal System

8 Pages

-

Seam normalizing

4 Pages

-

Induction coils

8 Pages

-

TERAC 25/40

2 Pages

-

HARDLINE VL 1000

2 Pages

-

Energy Management System

4 Pages

-

INDUCTION HEATING APPLICATIONS

24 Pages

-

Weldac

5 Pages

-

Sinac

5 Pages

-

HardLine

6 Pages