Catalog excerpts

Coating Removal System Proven performance

Open the catalog to page 1

Induction heating cuts coating removal times by as much as 90 per cent compared to alternative methods. It is also the safest, healthiest, most environmentally friendly coating removal method available. How it works Using induction heating to remove coatings has been an EFD Induction application for many years. Induction exploits the laws of electromagnetism to generate controllable heat. Alternating current flowing through a coil generates a magnetic field. When the magnetic field passes through the coating eddy currents are induced just under the surface of the metal substrate. It is the...

Open the catalog to page 3

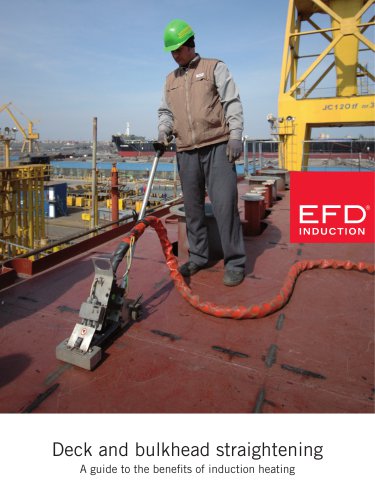

The Coating Removal System is a state-of-the-art induction heating tool that rapidly strips paint and tough, high-build coatings. Easy-to-use The Coating Removal System arrives at the job site start-up ready. Just plug the unit into the site’s AC power supply, connect the cooling hoses and choose which inductor you want to use. Once fitted, the clear, menu-based and multilanguage control panel ensures maximum ease-of-use. Portable Coating Removal Systems are compact and lightweight. No need for long cable runs, because the heating generator is close to the working area. Versatile The EFD...

Open the catalog to page 4

Easy-to-understand graphics Power level and heating cycle duration is automatically adjusted. i-Scan system Close control is desirable for a number of reasons. Due to the nature of many coating removal projects it’s common that the coil is moved manually. Therefore we need to take into account the difference in travel speed and potential increases in coating thickness. The Coating Removal System is capable of detecting and reacting to certain condition changes. When coupled with the unique i-Scan system it can not only detect speed change but also variations in the coating thickness and...

Open the catalog to page 5

A smarter way to strip coatings The Coating Removal System is a game-changer that facilitates removal of coatings from carbon steel, structural steel and other metal substrates. Appreciated in many industries • Ships / Marine • Storage tanks A better technology • Faster, cleaner, safer, quieter operation • User-friendly controls • Minimizes fumes & toxic dust • Eliminates workspace masking and encapsulation • Much easier clean-up • Rugged & reliable • Light weight, easy to move around worksites Method flexibility • Spot heating • Scanning • Freehand • Semi-automatic No limitations • Flat...

Open the catalog to page 6

Much easier clean-up. The coating material mainly peels off in flakes rather than being pulverized. The Coating Removal System is compact, light-weight, and easy to move around worksites. Appreciated in many industries Typical application sites are offshore rigs, onshore oil and gas facilities, fabrication and repair workshops, processing plants, pipelines, bridges and shipyards.

Open the catalog to page 7

Demonstrating global experience EFD Induction has worked closely with customers across the globe to develop the new Coating Removal System. The system has been developed to overcome bottlenecks and eliminate challenges that our customers have experienced during repainting projects and when removing coatings. You can take confidence from: Half a century of experience supplying induction heating solutions and the expertise this brings Our extensive range of products and systems which continue to benefit from investment in research and development and testing to ensure we provide the best...

Open the catalog to page 8All EFD Induction Group catalogs and technical brochures

-

HARDLINE CP 600

2 Pages

-

Crankshaft hardening

4 Pages

-

Hardline CIHM-C

2 Pages

-

Seam normalizing

4 Pages

-

Induction coils

8 Pages

-

TERAC 25/40

2 Pages

-

HARDLINE VL 1000

2 Pages

-

Energy Management System

4 Pages

-

EFD Induction

22 Pages

-

INDUCTION HEATING APPLICATIONS

24 Pages

-

Weldac

5 Pages

-

Sinac

5 Pages

-

HardLine

6 Pages