Catalog excerpts

EAS INSPECTION TABLES - EIT Safety instructions for model EIT3000

Open the catalog to page 1

SAFETY INSTRUCTIONS FOR USE OF THE EAS INSPECTION TABLE Do not exceed the posted weight limit of 3T. The inspection table should be blocked in back position with the stop block before rotating the top plate. The heaviest side of the mold should be placed on the fixed plate of the table. When opening or closing a large mold keep a safety strap/chain attached to a carne and the moving plates to ensure stability. Don’t slide the mobile plate too fast, proceed slowly to the rear stop and block the plate into position.

Open the catalog to page 2

PRECAUTIONS BEFORE FIRST USE All employee that will use the table should have read the user manual prior to use. EAS change systems accepts no responsibility what so ever when the table is used other than intended and when the weight limit has been exceeded. Never move the table while a mold is on top. When closing a mold push the mold and the mobile plate at the same time with the same force while making sure to never let fingers or other objects in between the mobile plate and stationary plate. The mold should be placed slowly onto the tables. Dropping of a mold onto the table could cause...

Open the catalog to page 3

Place the table on a stable floor and adjust the level by turning the adjustable feet. Remove the stop of the mobile plate and slide it to meet up with the fixed plate. (When shipping or moving the table to another location open the table and blocking the mobile plate. This will keep the plate in position and locked during transport.)

Open the catalog to page 4

Install the stop behind the mobile plate. The table is now ready to support a mold base. Don’t use the table without fastening the stop behind the mobile plate. This stop is an essential mechanical element of safety. If it is not properly fastened, there are risks of serious injuries. To unlock the rotating tray, make a 1/4 rotation And pull down the handle. (Use the same process on the fixed plate and mobile plate to rotate)

Open the catalog to page 5

MAINTENANCE Clean the tracks as needed and lube the ball bearings once a year. Inspect the frame for any cracks or damage that may lower the weight capacity of the frame.

Open the catalog to page 6

WARRANTY EAS change systems warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of shipment. If any such product proves defective during this warranty period, EAS change systems, at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the defective product. This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and care. EAS change systems shall not be obligated to...

Open the catalog to page 7

EAS Europe B.V. De Hooge Hoek 19A / 3927 GG Renswoude Phone: +31 318 477 010 / The Netherlands info@EASchangesystems.com EAS France S.A.R.L. 218, Voie Aristide Bergès / ZI Alpespace 73800 Sainte Hélène-du-Lac Phone: +33 4 79 65 04 10 / France easfr@EASchangesystems.com EAS Mold & Die Change System, Inc. EAS Mold & Die Change System, Inc. 200 Augusta Arbor Way, Suite B Greenville South Carolina - 29605 Phone: +1 864 603 3386 / United States of America easus@EASchangesystems.com Suzhou EAS Mold & Die Change Systems Co. Ltd. No.1188 Pangjin Road / Wujiang City / 215200 Phone: +86 51 26 30 91 /...

Open the catalog to page 8All EAS change systems catalogs and technical brochures

-

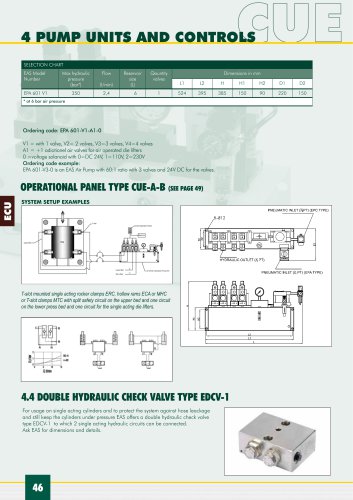

4 PUMP UNITS AND CONTROLS

1 Pages

-

EAS QDC Waterproof Pressmag

8 Pages

-

CQ MULTI COUPLING SOLUTIONS

4 Pages