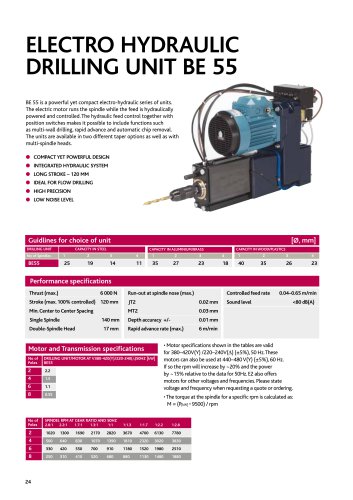

Catalog excerpts

SYSTEMS EN Manual Air Operated Drilling Unit Series BE 21

Open the catalog to page 1

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY ORIGINAL According to the EC's Machinery Directive 2006/42/EC, Annex 2B We, E2 Systems a division of Tubex AB Strömslundsgatan 3 507 62 Borås Sweden, declare that the partly completed machinery: Model: BE21x * Is designed to be embedded in a larger machinery or assembled with another machine, which together will constitute machinery covered by Directive 2006/42/EC "Machinery Directive" and which shall be constructed in compliance with this directive, and * Must not be put into service until the machinery, which the partly completed...

Open the catalog to page 3

Table of content: Page: Information about manufacturer 6 Description of the drilling unit 7 Installation of the drilling unit 8 Mounting of cutting tools 10 Description of limit switches 11 - pneumatic, installation and function 11 - electric, installation and function 11 Example of connection with limit switch 12 Spare parts drawing 16 Spare parts list 17, 18

Open the catalog to page 4

WARNING! - Ensure that the operator has read and understood this manual before the drilling unit is in use. - For security reasons, any modification of the drilling unit and it’s accessories, which may affect product safety, must be approved by the manufacturers technical manager. - The unit is intended for drilling, countersinking and reaming and should not be used for any other application, unless approved by the manufacturers technical manager - Always follow local security regulations regarding installation, operation and maintenance. - The drilling unit must be securely fixed and the...

Open the catalog to page 5

General recommendations - Apply a system for monitoring the tool in the machine. If no such system is at hand, we recommend user/operator to frequently control the tool. To ensure that no damages occurred. Thorough review of the unit Visual control of any external damages. Ensure there is possibility to quickly turn off the motor and air-supply and run a normal cycle without tool and material (to avoid further damages at the material and unit). Listen for noise from bearings and also control the run-out at the spindle nose. If not ok, unit has to be repaired and a new control for damages...

Open the catalog to page 6

Description of the drilling unit The BE21 is an air operated drilling unit with a feed. The design of the BE21 makes it very suitable for drilling blind holes, reaming and the like. Type and speed: See data label on drilling unit Serial number: See data label on drilling unit Description: 1. Main inlet port, G1/8'' (NPT) for forward feed. 2. Main inlet port, G1/8'' (NPT) for return feed. 3. Air motor directed exhaust port, G1/4" (NPT). 4. Adjustment nut for drilling depth/return position. 5. Adjustment nut for indication of home position. 6. Adjustment screw for working feed rate. 7. Key...

Open the catalog to page 7

Installation of the drilling unit This Drilling and Tapping Unit is only intended for use in machinery which applies to the Machine Directive 2006/42/EC. This Drilling and Tapping Unit is designed for normal drilling, countersinking, reaming and tapping. In applications requiring high-precision hole placement or when drilling into rounded or slanted surfaces, drill bushings must be used. To be able to use the unit, it must first be installed and fitted with control equipment. Regardless of how simple the installation is performed, the unit must be fitted with necessary protective devices to...

Open the catalog to page 8

Attachment The use of E2 Systems monting clamps and brackets for driling units is recommended. If other way of attachment is desired the front nut as shown in the below example shall be used. The drilling unit can be mounted vertically or horizontally. When attaching the drilling spindle upwards the feed force can be affected. Optional attachment should be discussed with E2's technician. Mounting of cutting tools The following cutting tools can be used with drilling unit: Drills, core drills, shank end mills, countersinkers, reamers or broaches. The drilling unit can be fitted with either...

Open the catalog to page 9

Setting 1. Ensure that the FRL unit is working properly. 2. The desired home position is set with adjusting nut (5). One revolution on the adjusting nut is 1 mm (.039 In). Adjusting nut (5) is locked with the locking nut in the set position. 3. The desired drilling depth is set with adjusting nut (4). One revolution on the adjusting nut is 1 mm (.039 In). Screwed down adjusting nut provides a short drilling depth and screwed up adjusting nut provides a long drilling depth. Adjusting nut (4) is locked with the locking nut in the set position. 4. The total stroke length is 50 mm (1 5/16''),...

Open the catalog to page 10

16. 1 pce 7-pole plug, male and female, with 2 m (6.56 Ft) cable. 17. 2 pcs electric micro-switches. M1 = upper micro-switch, actuated in rear spindle position = home position. M2 = lower micro-switch, actuated in front spindle position = return position 18. 2 pcs Adjusting nuts with locking nuts. Installation and function: The limit swiches provides electrical signals in both home and return position the plug (16). The micro-switches are universally connected to a 7-pole male plug for normally closed and normally open functions and requires no internal access work. During installation,...

Open the catalog to page 11

Example of connection with limit switch Pneumatic:

Open the catalog to page 12

Maintenance instruction Daily check: - Check the air-pressure on the FRL-unit, 6 – 7 bar (87 – 101.5 Psi). Max 7 bar (101.5 Psi). - Check for any leakages of air or oil. If a leakage is detected, contact service staff. Weekly check: - Check that the oil-mist lubrication is working, approx. 1 drop/10-20 cycles. 1 drop = 15 mm3 (.000528 fl.oz. (UK), .000507 fl.oz. (US)) - Check that the drilling unit is clean. Monthly check: - Check that no abnormal play is present in the drilling spindle. - Check that external silencer is not clogged. - Check that the air filter in the FRL unit is working or...

Open the catalog to page 13

Thrust, axial force Power, air motor Stroke CC spindle spacing Run-out at spindle nose Depth, accuracy Working pressure range Air consumption Ambient temperature Sound level Spindle thread for chuck Chuck Electric limit switches Max. 665 N (150 Lbf) See Power table below. Max. 50 mm (1 5/16'') Min. 45 mm (1 3/4'') Max. 0,05 mm (.002 In) +/- 0,01 mm (.0004 In) 6 - 7 bar. Max 7 bar (85 - 100 Psi. Max. 101.5 Psi) < 0,3 Nm3/min (< 12 Cfm) + 10° - +40° C. (+50° - +104° F) 70 dB(A) 3/8'' - 24 UNF As standard the drilling unit is fitted with an ordinary key chuck 0 0,5 - 6,5 mm (,02 - 1/4''). A...

Open the catalog to page 14All E2 Systems catalogs and technical brochures

-

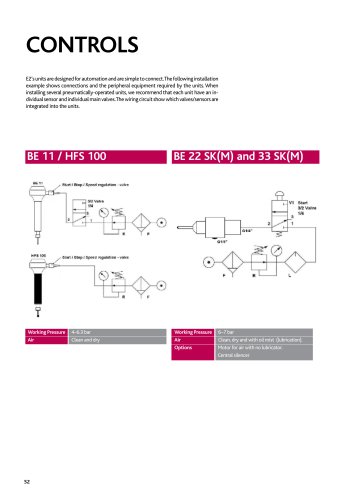

Controls

5 Pages

-

Tool Holders

3 Pages

-

Cpst-effective Automation

6 Pages

-

Cost-effective Automation

4 Pages

-

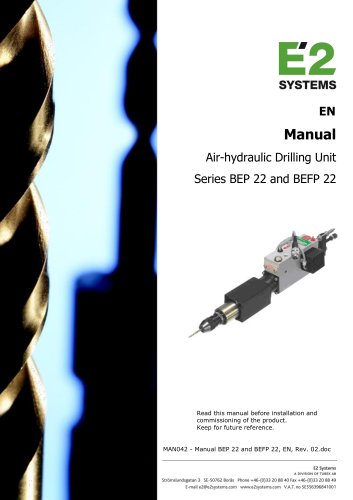

Series BEP 22 and BEFP 22

23 Pages

-

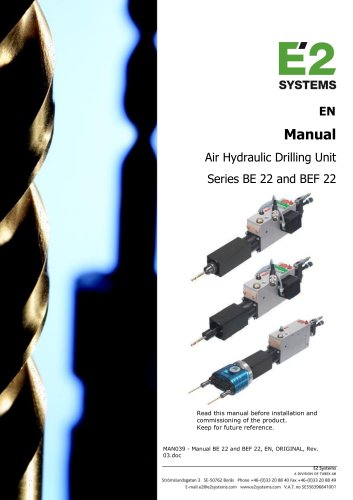

Series BE 22 and BEF 22

23 Pages

-

Series BE 22 SK

15 Pages

-

E2-catalog

30 Pages