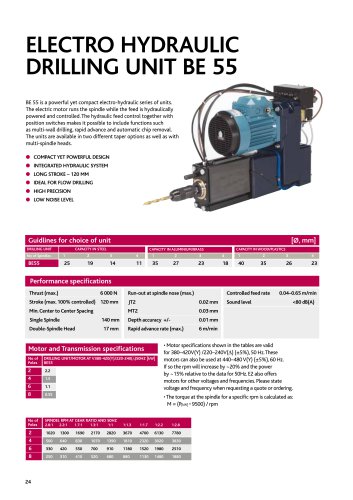

Catalog excerpts

Read this manual before installation and commissioning of the product. Keep for future reference.

Open the catalog to page 1

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY ORIGINAL According to the EC's Machinery Directive 2006/42/EC, Annex 2B We, E2 Systems a division of Tubex AB Strömslundsgatan 3 507 62 Borås Sweden, declare that the partly completed machinery: Model: BE11 * Is designed to be embedded in a larger machinery or assembled with another machine, which together will constitute machinery covered by Directive 2006/42/EC "Machinery Directive" and which shall be constructed in compliance with this directive, and * Must not be put into service until the machinery, which the partly completed...

Open the catalog to page 3

Page: Table of content 3 Information about Manufacturer 5 Spare parts drawing and Spare parts list 10

Open the catalog to page 4

WARNING! - Ensure that the operator/user has read and understood this manual before the unit is in use. - For security reasons, any modification of the unit and it’s accessories, which may affect product safety, must be approved by the manufacturers technical manager. The BE 11 unit is intended for 11 drilling and should not be used for any other application, unless approved by the manufacturers technical manager. - Always follow local security regulations regarding installation, operation and maintenance. - The BE 11 drilling unit must be securely fixed and the installation instructions...

Open the catalog to page 5

General recommendations Apply a system for monitoring the tool in the machine. If no such system is at hand, we recommend user/operator to frequently control the tool. To ensure that no damages occurred Thorough review of the unit Visual control of any external damages. Ensure there is possibility to quickly turn off the motor and air-supply and run a normal cycle without tool and material (to avoid further damages at the material and unit). Listen for noise from bearings and also control the run-out at the spindle nose. If not ok, unit has to be repaired and a new control for damages will...

Open the catalog to page 6

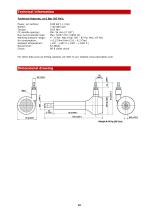

Description of the units High Precision Drilling Unit BE 11 with a basic design based on a patented air-driven turbine motor. The drive unit is powered without intermediate gears and features variable speed control up to 80 000 rpm. A special high-speed precision bearing makes the units extremely quiet. BE 11 Type and Serial no.: See data label on unit. Description: 1. Air exhaust with silencer. 2. Spindle with Collet Chuck ER 8, Ø1,0 – 5,0 mm (.039 - .197 In). 3. Housing. 4. Connection with Start / Stop / Speed regulating valve. 5. End cap.

Open the catalog to page 7

Installation The BE 11 drilling unit is only intended to be used in machines that meet the machinery directive 2006/42/EC. WARNING! Never use the BE 11 drilling unit without being securely fastened and that appropriate security arrangements have been organised. Be careful with rotating and moving parts, to avoid personal injuries. Ensure that the drilling unit is disconnected from the main air-supply, before any change of tool or maintenance. Air supply: A complete air preparation unit (FR unit) with a flow capacity exceeding 0,12 Nm3/min (12 Cfm), air-filter with 5 μm (2500 mesh)...

Open the catalog to page 8

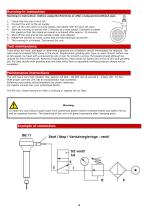

Running-in instruction Running-in instruction: (before using the first time or after a long period without use). 1. 2. 3. 4. Check that the unit is shut off. Connect the unit to the air supply. Turn on the unit, start at a slow speed, and adjust with the shut-off valve. Start the running-in period with 3 minutes at a slow speed. Gradually increase the speed so that the maximum speed is achieved after approx. 10 minutes. 5. Shut off the unit and let the spindle rotate until stopped. 6. Rotate the spindle by hand. Listen that the ball bearings sounds OK. 7. The running-in is finished....

Open the catalog to page 9

Power, air-turbine : Speed: Torque: CC spindle spacing: Run-out at spindle nose: Working pressure range: Air consumption : Ambient temperature: Sound level: Chuck: For other data such as drilling capacity we refer to our website www.e2systems.com.

Open the catalog to page 10

Maintenance kit, BE 11 / HFS 100041R000012 7_2 Ball bearing_ (All above parts must be replaced at all repairs.) _Other spare parts:_ _3_1 Spindle BE 11/HFS 100_ 31_3 O-ring for shut off valve, 010,1x1,6 Nitril 32_1 Shut off valve with hose and connection. _1 Hose 1/4'', length 1000 mm._ _1 Hose clamp_

Open the catalog to page 11

The warranty period for the product is 12 months after installation/ commissioning or 18 months after delivery, which of these occurs first, and provided that the product installed/stored in a satisfactory manner and that the product is used in normal operation, the mounting/ clamping and handling conditions. The warranty is not valid if unauthorized change/modification have been performed on the product and that this may make the product unsafe. Drilling / Grinding unit, Type BE 11 / HFS 100 Housing : Aluminium End cap : Plastic Other parts : Aluminium and steel Gaskets : Rubber Housing...

Open the catalog to page 12All E2 Systems catalogs and technical brochures

-

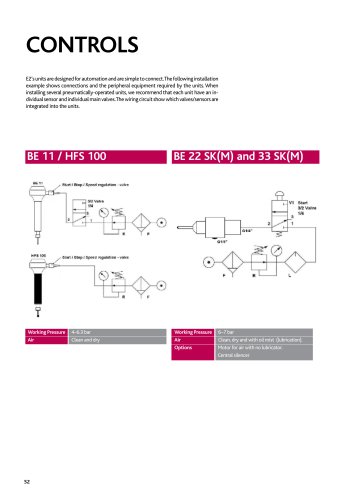

Controls

5 Pages

-

Tool Holders

3 Pages

-

Cpst-effective Automation

6 Pages

-

Cost-effective Automation

4 Pages

-

Series BEP 22 and BEFP 22

23 Pages

-

Series BE 22 and BEF 22

23 Pages

-

Series BE 21

19 Pages

-

Series BE 22 SK

15 Pages

-

E2-catalog

30 Pages