Catalog excerpts

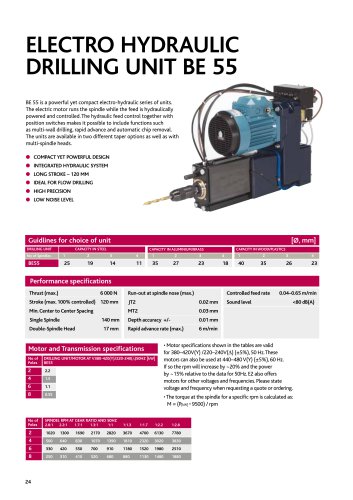

BE 55 is a powerful yet compact electro-hydraulic series of units. The electric motor runs the spindle while the feed is hydraulically powered and controlled. The hydraulic feed control together with position switches makes it possible to include functions such as multi-wall drilling, rapid advance and automatic chip removal. The units are available in two different taper options as well as with multi-spindle heads. • IDEAL FOR FLOW DRILLING • HIGH PRECISION Guidlines for choice of unit DRILLING UNIT Thrust (max.) Stroke (max. 100% controlled) Min. Center to Center Spacing Single Spindle 140 mm Run-out at spindle nose (max.) Rapid advance rate (max.) 6 m/min Controlled feed rate 0.04-0.65 m/min Motor and Transmission specifications • Motor specifications shown in the tables are valid for 380-420V(Y) /220-240V(A) (±5%), 50 Hz. These motors can also be used at 440-480 V(Y) (±5%), 60 Hz. If so the rpm will increase by ~20% and the power by ~15% relative to the data for 50Hz. E2 also offers motors for other voltages and frequencies. Please state voltage and frequency when requesting a quote or ordering. • The torque at the spindle for a specific rpm is calculated as: M = (P[kw] x 9500) / rpm

Open the catalog to page 1

You can download 2D CAD-drawings and 3D CAD-models on www.e2systems.com. Necessary components Accessories MULTI-SPINDLE HEADS On www.e2systems.com you can find more information as well as the same information as above in imperial units. When requesting a quote or ordering, please state: Model, Chuck (collet size), Control system, Spindle rpm, Motor Power and Front or Backward Motor orientation.

Open the catalog to page 2All E2 Systems catalogs and technical brochures

-

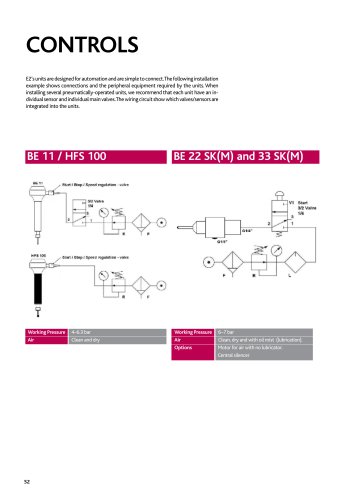

Controls

5 Pages

-

Tool Holders

3 Pages

-

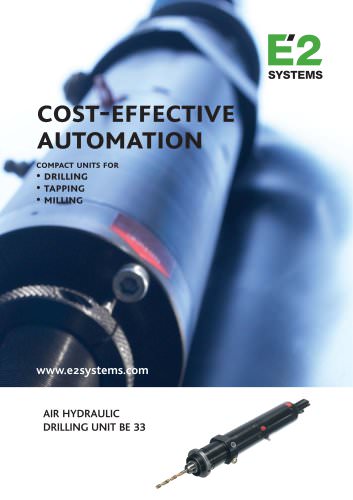

Cpst-effective Automation

6 Pages

-

Cost-effective Automation

4 Pages

-

Series BEP 22 and BEFP 22

23 Pages

-

Series BE 22 and BEF 22

23 Pages

-

Series BE 21

19 Pages

-

Series BE 22 SK

15 Pages

-

E2-catalog

30 Pages