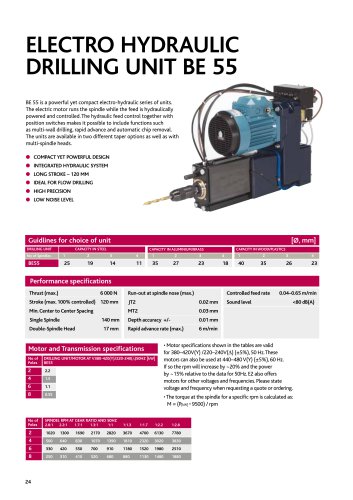

Catalog excerpts

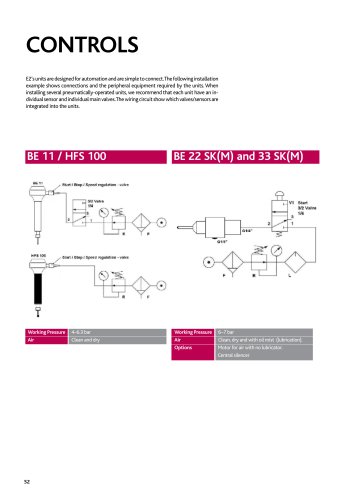

controls E2’s units are designed for automation and are simple to connect.The following installation example shows connections and the peripheral equipment required by the units. When installing several pneumatically-operated units, we recommend that each unit have an individual sensor and individual main valves.The wiring circuit show which valves/sensors are integrated into the units. Working Pressure 4–6.3 bar Working Pressure Air Clean and dry Air Options 6–7 bar Clean, dry and with oil mist (lubrication). Motor for air with no lubricator. Central silen

Open the catalog to page 1

BE(S) 21 Pneumatic limit switches M1 Electric limit switches The limit switches come with either 1.2 m hose (Pn) or 1.2 m cable (El). We recommend a delayed return for accurate drilling depth tolerances and for countersinking. The rotation of the spindle starts when the unit is fed air for forward feed. During the return the rotation gradually slows to a complete stop. Working Pressure Air Options 6–7 bar Clean, dry and with oil mist (lubrication). Motor for air with no lubricator. Emergency break valve parallel to M2, which stops the unit and returns it to home position. Central silencer...

Open the catalog to page 2

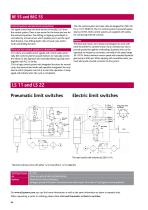

BE 22 and BE 33 Pneumatic limit switches Electric limit switches The limit switches comes with either 2 m hose (Pn) or 2 m cable (El). We recommend a delayed return for accurate drilling depth tolerances and for countersinking. When the main valve is actuated, spindle feed and rotation commence. When the valve is released, the spindle returns to its start position and the motor’s rotation ceases. Working Pressure Air Options 6–7 bar Clean, dry and with oil mist (lubrication). Motor for air with no lubricator. Emergency break valve parallel to M2, which stops the unit and returns it to home...

Open the catalog to page 3

BE 48 and BEG 48 Pneumatic limit switches V5 Electric limit switches The max load for the switches at 220 V is 1A. Linear transducer (optional) for full control of the stroke. Ideal for the control of automatic chip removal, multiwall drilling, tapping, reaming etc. The limit switches comes with either 2 m hose (Pn) or 2 m cable (El). We recommend a delayed return for accurate drilling depth tolerances and for countersinking. Working Pressure Air Options Motor Max 8 bar Clean and dry. Lubrication is not necessary but increases the life span of the unit. Emergency break valve parallel to V4...

Open the catalog to page 4

BE 55 and BEG 55 Control systems and electrical connections: The signal comes from the limit sensors of the BE(G) 55 from the control system. There is one sensor for the home and one for the extracted position. The drilling or tapping cycle/depth is controlled by a linear sensor which enables you to set the rapid feed distance, max drilling depth, chip-removal cycle and/or multi-wall drilling function. There are two control systems to choose from: C1A where you handle sensor signals and control valves externally (the control system has push buttons to manually control the valves for fast...

Open the catalog to page 5All E2 Systems catalogs and technical brochures

-

Tool Holders

3 Pages

-

Cpst-effective Automation

6 Pages

-

Cost-effective Automation

4 Pages

-

Series BEP 22 and BEFP 22

23 Pages

-

Series BE 22 and BEF 22

23 Pages

-

Series BE 21

19 Pages

-

Series BE 22 SK

15 Pages

-

E2-catalog

30 Pages