Catalog excerpts

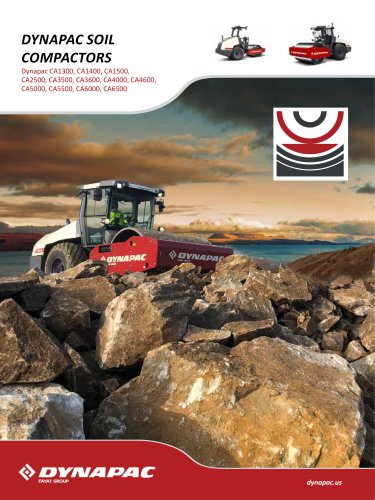

DYNAPAC SOIL

Open the catalog to page 1

PRESENTING THE COMPLETE DYNAPAC SOIL COMPATOR RANGE These machines and their variants, are the fifth generation of Dynapac CA single drum vibratory rollers. With their state-of-the-art designs and unique features, they represent yet another example of Dynapac’s innovative thinking. A NEW PERSPECTIVE ON COMPACTION FAST, SIMPLE, PROFITABLE THE COMPLETE PICTURE There is much more to soil compaction than the roller. When we developed this generation, we applied our unmatched know-how in the field of soil compaction to the entire compaction mission. This ranges from planning the task, through...

Open the catalog to page 2

EXPERTISE IN EVERY ASPECT Experience is the base of excellence. Dynapac will always help you to reach perfection.

Open the catalog to page 3

DYNAPAC SOIL COMPACTOR RANGE SMALL, MEDIUM, LARGE OR XL The Dynapac CA2500 - CA4600 are medium heavy vibratory soil compactors, typical utility machines, designed for long working days in tough applications. All types of base courses and reinforcement courses can be compacted to considerable depth. The 35 mm hitch drum ensures excellent resistance to wear - even in compaction operations on rockfill. The padfoot version has it’s major range of application on cohesive material and disintegrated rock. All types of base courses and subbase courses can be compacted. Rock fill The small Dynapac...

Open the catalog to page 4

- DYNAPAC OFFERS THEM ALL Operating mass Static linear load Drum width The CA702 is Dynapac’s heaviest vibratory soil compaction roller. The machine has been specially developed for the heaviest large-scale compaction work on earth, rockfill and most types of soils and clays. Typical applications include dams, airfields, harbors and major railway and road projects. Rock fill The CA5000, CA5500, CA6000 and CA6500 are heavy rollers designed for the toughest compaction applications. Rockfill can be compacted in 2-meter thick layers, in which the size of the rocks can be up to 1 meter in...

Open the catalog to page 5

MAKE USE OF SCIENCE IN COMPACTION PREPARATION - COMPBASE SOFTWARE Performance Protocol CompBase is the only recommendation tool in the industry that can provide detailed compaction data and capacity information based on full-scale tests. The machine and method selection is based on the material to be compacted and provides information on the expected depth effect and degree of compaction after any given number of passes. In addition to this; CompBase recommends suitable amplitude and rolling speed for optimum performance. PERFORMANCE - DYNAPAC COMPACTION OPTIMIZER (CA3500/4000/5000/6000)...

Open the catalog to page 6

Prior to compaction - Preparation MISSION PLANNING FOR EFFICIENCY AND ECONOMY MAP GROUND CONDITION Map the ground condition and the material to be compacted. If your CA roller is equipped with a Compaction Meter with DCA-S (with GPS), you can run the machine over the area in advance. This will give you a chart showing ground condition and material to be compacted, at the same time revealing weak areas before you start rolling. SELECT MACHINE AND COMPACTION STRATEGY Dynapac CompBase software bases the selection of machine and method on the material to be compacted. The software provides...

Open the catalog to page 7

During compaction - Performance LOWER COST PER COMPACTED CUBIC METER FEEDBACK ON PROGRESS AND POSITION Your fifth generation Dynapac CA soil compactor is warmed up and ready to roll. Start compacting and the Dynapac CA roller, with Compaction Meter and Compaction Analyzer, gives you continuous information on the increase in compaction and reveals weak areas. Compaction results are displayed on the computer screen, allowing you to focus the compaction energy on the ground surfaces that need additional compaction. The screen also displays the position of the roller in relation to a selected...

Open the catalog to page 8

THE MACHINE TAKES THE STRAIN The ergonomically designed, air-conditioned cabs on the new generation offer a high level of operator comfort and good visibility over the work area and surroundings. The noise level from the engine is very low. A feature unique to Dynapac CA rollers is a spin-around seat, steering module and display cluster, which allows movement of up to 180 degrees without stress to the neck or body. SAFETY FIRST Safety functions include Electronic Drive Control with a “quick brake” function, which shortens braking distances if the lever is moved very fast, and a tilt...

Open the catalog to page 9

During compaction PERFORMANCE/DURABILITY Thick drum shell ensures compaction performance and long running time before change. PERFORMANCE Easy accessable scrapers divided to follow drum movement and replacement at low cost. COMPACTION PERFORMANCE Several compaction data to choose among. STATIC LINEAR LOAD in steps of 5 kg/cm means there‘s a machine for all needs.

Open the catalog to page 10

LIGHTS Night or day? Choose working/driving lights according to your needs. OPERATOR´S STATION Three main configurations to choose from, and numerous options. PERFORMANCE Clean inlet air (combination and cooling) taken in as high as possible. SERVICEABILITY Cross-mounted engine gives unique service access SAFETY Sloping engine hood and 1x1 meter view front & rear. SAFETY/PERFORMANCE Heavy duty rear axle with failsafe brakes. ENGINES FROM CUMMINS OR DEUTZ 4 or 6 cylinders, Stage IIIA (Tier3) or Stage IIIB (Tier4i), your choice.

Open the catalog to page 11

AFTER COMPACTION - PROTOCOL DOCUMENTING THE MISSION TO ASSURE QUALITY DYNAPAC’S DOCUMENTATION SYSTEM Using the built-in Compaction Meter with Compaction Analyzer DCA-S with GPS (if fitted), each stage of the compaction work is documented and all measured values can be stored. The analysis function enables the compaction work to be replayed. MACHINE USE - LEVEL OF EFFICIENCY It enables the complete project to be studied in the office after the task is completed to see how many runs have been allocated over the surface and the level of compaction achieved. It thus provides the opportunity to...

Open the catalog to page 12

A WORLD FIRST, WITH UNIQUE ADVANTAGES ENGINES FROM CUMMINS OR DEUTZ The new soil vibratory rollers are the first of their type with cross-mounted engines at the rear – and this provides excellent serviceability. They can be equipped with Stage IIIB engines (Tier 4i) from Cummins (4 cylinders) or Deutz (6 cylinders). VERY LOW NOISE LEVEL The noise level is very low, since the cooling air intake is placed at the top of the hood with the outlet down the sides, combined with the ejector exhaust outlet. CLEAN INLET AIR The position of the combustion air intake also has the advantage of keeping...

Open the catalog to page 13All Dynapac Road Construction Equipment catalogs and technical brochures

-

Dynapac CA250D

2 Pages

-

Dynapac CA1300PD

2 Pages

-

CO6200 VI

4 Pages

-

CA15PD

2 Pages

-

DYNAPAC LIGHT COMPACTION

16 Pages

-

S100

4 Pages

-

Dynapac F1200C

2 Pages

-

Dynapac F1000W (T4)

3 Pages

-

Dynapac F1000T (T4)

3 Pages

-

DYNAPAC CP2700

8 Pages

-

DYNAPAC CP275

8 Pages

-

DYNAPAC CS1400N

2 Pages

-

DYNAPAC CT3000

8 Pages

-

Dynapac V5100TVH

1 Pages

-

DYNAPAC TANDEM ASPHALT ROLLERS

12 Pages

-

Highway Class Dynapac Pavers

12 Pages

-

Dynapac Pivot Asphalt Roller

4 Pages

-

Dynapac Tamping Compactor

8 Pages

-

Dynapac City Paver Range

12 Pages

-

Dynapac Mobile Feeder

12 Pages

-

Dynapac Compact Paver Range

16 Pages

-

Dynapac Large Paver Range

16 Pages

-

Dynapac Compact Planer Range

12 Pages

Archived catalogs

-

DYNAPAC SOIL COMPACTORS_2019

20 Pages

-

rammer

13 Pages

-

vibratory plate compactor

13 Pages

-

asphalt planer

14 Pages

-

compact asphalt planer

1 Pages

-

wheeled asphalt paver

13 Pages

-

pneumatic tired roller

17 Pages

-

Combination Roller

13 Pages