Website:

DYNABRADE Europe

Website:

DYNABRADE Europe

Group: DYNABRADE SARL

Catalog excerpts

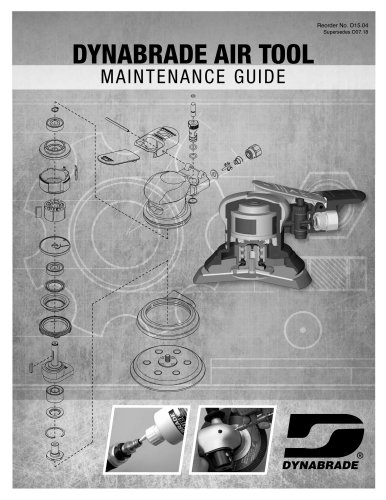

DYNABRADE AIR TOOL MAINTENANCE GUIDE

Open the catalog to page 1

CAREFULLY READ ALL INSTRUCTIONS BEFORE OPERATING, MAINTAINING OR SERVICING ANY POWER TOOL CONTACT YOUR DYNABRADE REPRESENTATIVE FOR PRICING OF PRODUCTS SHOWN IN THIS GUIDE

Open the catalog to page 2

For Various Abrasive Power Tools Safety Booklet included with tool must be read and understood before operating any portable pneumatic tool! • This page must be read and understood by operating personnel and safety manager. Protection to operating personnel, as well as adjacent areas, shall be maintained at all times. • Always comply with: General Industry Safety & Health Regulations (www.osha.gov), EN Standards for Hand Held Non-Electric Power Tools (www.cen.eu), American National Standards Institute (www.ansi.org) and Regional Regulations. • Additional safety reference materials are...

Open the catalog to page 3

COMPRESSED AIR SUPPLY SYSTEM Lubricator Setting 1 Drop /Minute per 20 SCFM Dynabrade recommends one drop of air lube per minute for each 20 SCFM (566 L/Min) Example: If the tool specifications state 40 SCFM (1,133 L/Min), set the drip rate of your lubricator at 2 drops per min. CLOSED LOOP PIPE SYSTEM (SLOPED IN THE DIRECTION OF AIR FLOW) REGULATOR FILTER TO TOOL STATION 6 BALL VALVE DRAIN VALVE DRAIN VALVE COUPLER BALL VALVE

Open the catalog to page 4

COMPRESSED AIR SUPPLY SYSTEM (CONT.) COMPRESSED AIR SUPPLY SYSTEM (CONT.) COMPRESSED AIR SYSTEMS SHOULD INCLUDE THE FOLLOWING: 1. AIR INTAKE FILTER Incoming air must be filtered to remove dust and other contaminants. 2. AIR COMPRESSOR The filtered air is compressed using; a screw, or reciprocating compressor. 3. AIR COOLING/DRYING Air usually contains a significant amount of water vapor. As air is compressed its temperature is dramatically raised, so cooling of the compressed air is required. As the air is cooled, the water vapor condenses and water is removed. 4. AIR STORAGE A tank called...

Open the catalog to page 5

SELECTING A COMPRESSOR (CONT.) C) COMPRESSOR HORSEPOWER (hp) – Use the determined total demand SCFM (L/Min) and add approximately 20% for system variables. Add ______% for (your) future growth. If the above total equals less than 100 SCFM(2,832 L/Min) divide this total by 4 to find the compressor hp. If the total is over 100 SCFM(2,832 L/Min) divide by 5 to find the compressor hp. Example: System requirements = 165 SCFM (4,673 L/Min) @ 100 PSIG (6.9 Bar) 165 ÷ 5 = 33 hp. Suggested Compressor Size: ~30 to ~40 hp. AIR STORAGE TANK SIZE - As a general rule, the larger the tank (receiver) the...

Open the catalog to page 6

PREVENT AND ELIMINATE AIR SUPPLY RESTRICTIONS Common causes of restriction: • The air supply hose is too long. • The inside diameter (i.d.) of the hose is too small. • The air connections or fittings have an inside diameter that is too small. • There are too many air connections or fittings being used. • If an inline filter is being used, the unit may be too small or the filter element may be plugged. • If an inline regulator is being used, the unit may be to small, not adjusted properly or defective. • The air supply hose, air fitting, air tool inlet or air tool exhaust may be...

Open the catalog to page 7

AIR PLUGS AND COUPLERS PLUGS COMPARE AIRFLOW SCFM(LPM) Common Plug HOW TO MEASURE A TYPICAL PLUG Dynabrade Plug NPT (National Pipe Thread) is the thread size. (i.e. 1/4" NPT) Thread Size • Dynbrade plugs provide maximum air flow NOTE: All information is based on the size of the INSIDE DIAMETER @ 90 PSIG (6.2 Bar) in conjunction with the mating coupler. • Plugs are available in the following sizes: 1/4", 3/8"and 1/2" NPT. IMPORTANT: It is not always advisable to use an air plug and coupler to connect an air tool to the air supply hose. Contaminants can enter the air tool through plug and...

Open the catalog to page 8

1. REDUCE OR ELIMINATE CONDENSATION (WATER VAPOR) FROM THE AIR SUPPLY • Water traps and drains • After-coolers • Refrigerated air dryer 2. PREVENT DEBRIS FROM ENTERING THE AIR MOTOR • Filter the air. • Keep the air inlet connections, plugs and couplers clean, free of dust and debris. • Keep exhaust mufflers and elements in place. Muffler elements provide a barrier that will prevent dust from being pulled into the air motor. • Do not use compressed air to blow-off the tool, this could force debris into bearings. 3. LUBRICATE THE AIR MOTOR • Use an automatic lubricator to supply the correct...

Open the catalog to page 9

95848 Gear Oil 2.5 oz. (74 ml) tube • Formulated for geared tools utilizing a wick-type lubrication system. • Failure to lubricate will cause premature gear failure. Dynabrade Air Lube (10W/NR) • Formulated for pneumatic equipment. • Absorbs up to 10% of its weight in water. • Prevents rust and formation of gum/sludge for longer tool operation with greater power and less downtime. 95821 95843 Grease • Multi-purpose grease for all types of bearings, cams and gears. • High film strength; excellent resistance to water, steam, etc. • Workable range: 0°F (-17°C) to 300°F (148°C). 95542 10 oz....

Open the catalog to page 10

• Only connect once... permanently mounts between coupler and air hose to purge air line of water and contaminants before starting up air tools. • Durable aluminum construction, weighs only 2 oz. (0.06 kg). Part No. 94467 Safety Tip Design • Reduces line pressure down to 30 PSIG (2 Bar). • Meets O.S.H.A. requirements of special relief hole in nozzle, which limits pressure to 30 PSIG (2 Bar) when dead-ended and used on an air line of 150 PSIG (10.3 Bar) or less. • 10.3 Bar (150 PSIG) maximum Proper Installation for DynaJet Blow Gun Connection Part Number...

Open the catalog to page 11

DROP-IN MOTORS/TUNE-UP KITS • Drop-In Motors are complete replacement air motor assemblies. • Tune-Up Kits contain assorted and high wear replacement parts. To view a complete offering, go to Dynabrade.com Drop-In Motor GUIDELINES FOR INSTALLING A DROP-IN MOTOR Installing a Drop-In Motor is relatively simple to perform. However, there are some necessary steps to follow to be successful. 1) Before attempting the installation of a drop-in-motor, review and understand the specific power tool “Disassembly and Assembly Instructions”. Note: Though a technician is not disassembling every...

Open the catalog to page 12All DYNABRADE Europe catalogs and technical brochures

-

Dynabrade Abrasive System Products

100 Pages

-

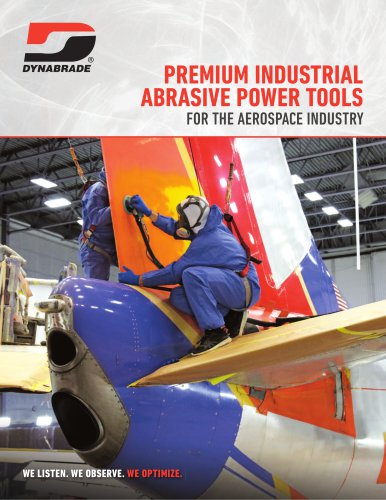

TOOLS FOR THE AEROSPACE

16 Pages

-

Dynabrade Clean Air Solution

116 Pages

-

Dynabrade Backing Pads

8 Pages

-

Dynabrade Metalworking D20-10

32 Pages

-

MINI-RAPTOR VAC PACKS

6 Pages

-

SANDING SOLUTIONS

6 Pages

-

Steel Housing Die Grinders

4 Pages

-

Performance Assurance

2 Pages

-

dybabrade air tool

20 Pages

-

Performance Assurance

2 Pages

-

Mini Raptor Vac Packs

6 Pages

-

Tools for Aerospace Industries

20 Pages

-

51520

2 Pages

-

Filter-Regulator-Lubricator

1 Pages

-

COST SAVINGS PROGRAM

4 Pages

-

RAPTOR VAC CART

4 Pages

-

600 SERIES

2 Pages

-

300 SERIES

2 Pages

-

DYNACUT EXTREME ORANGE

2 Pages

-

DYNORBITAL EXTREME

6 Pages

-

DYNISHER

4 Pages

-

DYNAPOINT II

2 Pages

-

Downdraft Sanding Tables

2 Pages

-

Dynabrade Abrasive Power Tools

96 Pages

-

Wrenchless Pencil Grinder

2 Pages

-

Quick-Change Pencil Grinder

2 Pages

-

DynaPen Series

4 Pages

-

Pencil Filer from Dynabrade

2 Pages

-

Industrial Quality Drills

12 Pages

-

Tools for the Wind Energy

16 Pages

-

Tools for the Marine Industry

32 Pages

-

Steel Housing Die Grinders

4 Pages

-

Vacuum Tools & Accessories

64 Pages