Website:

DWT GmbH

Website:

DWT GmbH

Catalog excerpts

BWC Boiler panel cutting system type BWC The heat-affected zone as well as the rework, in contrast to flame cutting, is significantly reduced. For maintenance and inspection, boiler manufacturers use a membrane wall cutting system in boiler technology. During maintenance and inspection, boiler use a membrane wall separation system there. This makes tube end preparation on the fin tubes faster and more effective. A heat-affected zone is avoided, thus reducing costly expensive rework. The system increases safety at the workplace through stable guidance of the cutting tool and reduces wear of the cutting discs through precise guidance. The entire system is guided by a smooth-running tool slide. The advantages of the panel wall saw are increased work safety, less reworking, less wear on the cutting disc and high productivity due to faster cutting. • Equipped with pneumatic or electric motor • Cut membrane walls quickly & effectively • High productivity and cutting quality • Less rework • Higher safety of operator Depth of cut with new cutting blade [mm] Total length guide rail [m] Length guide rail [m] Weight guide rail [kg] Nominal input [W] Power[W] Diameter cutting blade [mm]

Open the catalog to page 1All DWT GmbH catalogs and technical brochures

-

TOOLING

1 Pages

Archived catalogs

-

New Motor Option

1 Pages

-

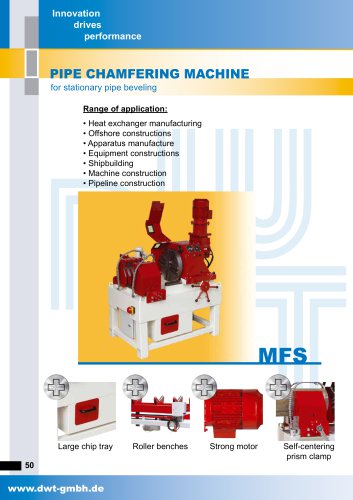

PIPE CHAMFERING MACHINE

2 Pages