Website:

DURAG Group

Website:

DURAG Group

Group: Durag Group

Catalog excerpts

SSMITSVONK A Member of DURAG GROUP Product Overview Gas Fired Igniters Pilot Burners |gnition Lances for Flares, Furnaces and Boilers DU RAG GROUP smart solutions for combustion and environment

Open the catalog to page 1

A Member of DURAG GROUP Introduction For more than 65 years Smitsvonk has been making low-tension high-energy ignition and control systems for industrial combustion processes. These electrical and electronic ignition systems are applied world-wide. They are characterized by a high degree of reliability under demanding conditions. Ignition is not effected by dirt, humidity, extreme temperatures or aggressive gases. History The company was founded in 1947 by Mr. Wietze Beye Smits. He was the inventor of the High-Energy (Low-Tension) Ignition System. Before the production of industrial...

Open the catalog to page 2

A Member of DURAG GROUP The Smitsvonk Ignition Principle Smitsvonk’s low tension high energy ignition system is designed to meet the requirements of reliable ignition for many industrial applications. The system is based upon the principle of a capacitor discharge over a special discharge surface. This surface consists of an isolator with semiconductor properties. The isolator and positive and negative electrodes are integrated into a high temperature resistant spark plug. When a charged capacitor is connected, it will be discharged via the spark plug producing sparks, even under wet or...

Open the catalog to page 3

A Member of DURAG GROUP Flare Ignition Systems Flaring systems in a refinery, petrochemical plant or steel plant ensure the safe and efficient disposal of relieved gases. A flare is expected to operate twenty-four hours a day. The flare system must be in service for several years without a need for maintenance. Therefore proper design and operation are extremely important. Ignition of the waste gases can be done by pilot burners (flame) or for some applications by ignition lances (spark). The ignition system must reliably ignite the waste gas of the flare. If the ignition system fails,...

Open the catalog to page 4

A Member of DURAG GROUP Pilot Burner Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk's pilots provide reliable ignition and stable burning even under the most difficult climate conditions. Features • High energy ignition • Ignition by three integrated spark plugs • Long lifetime, longer maintenance intervals • Insensitive to moisture and dirt • Complete delivery; cables,...

Open the catalog to page 5

A Member of DURAG GROUP DURAG smart solutions for GROUP combustion and environment 6

Open the catalog to page 6

A Member of DURAG GROUP Pilot Burner Selection Table for Large Flares (Heavy Duty Applications) Model Number Heat Gas Flow Release in nm3/hr based on Natural Gas in kW Required Pressure natural gas or propane/ 3 integrated spark butane or refinery gas plugs at 1.8 m from the top (max. 10% H2) option for thermocouple: HD60AF19-2326-360-25-DTW HD60AF19-2326-360-25-2TW option for extra flame front ignition: HD60AF19-2326-360-25-TW-FFG HD60AF19-2500-360-TW length: 2500 mm 3 spark plugs and extra flame front tube angled natural gas or propane/ 3 integrated spark butane or refinery gas plugs at...

Open the catalog to page 7

A Member of DURAG GROUP Date Preferred contact by Tel. Email Customer/ Partner Contact project Location - country Plant type Flare tip type Pipe Flare Steam Assisted Air Assisted High Pressure (Sonic) Ground Flare Pit Flare Flare tip manufacturer Flare tip diameter " mm Total height complete flare stack Drawing of the flare tip available Yes No Waste gas flow min. max. Waste gas composition Pilot burners: required number Pieces Pilot burners: ignition method Flame Front High Energy Flame Front and High Energy Pilot burners gas pressure...

Open the catalog to page 8

A Member of DURAG GROUP Continuous Electronic Spark Flare Ignition Features • No gas consumption; offering considerable savings • Substantial reduction of investment costs since no gas lines, valves, instrumentation or electrical control system for the pilot burner are needed Applications • Coke oven flares • Pipe flares with hydrogen in the waste gas • Temporary flares from tank farms DURAG smart solutions for GROUP combustion and environment Description Smitsvonk has decades of experience with direct electric ignition of flare units. A reproducible, high energy, highly reliable...

Open the catalog to page 9

Ignition Lances Direct ignition of (pilot) burners, flares and other processes Features • Built to client specifications • High temperature resistance • Long life time • Easy fit cable connectors • Insensitive to moisture • Exchangeable spark plug Straight ignition connector example of a straight ignition lance

Open the catalog to page 10

A Member of DURAG GROUP Accessories High temperature (775 °C) ignition cable with connector and SST protection hose • High temperature (775 °C) thermocouple cable with connector and SST protection hose SST junction box for ignition or thermocouple signal • Low temperature ignition cable • Low temperature thermocouple cable Ignition and control unit (see on pages 17 and 18) Spark Plugs • All types of low tension high energy spark plugs to replace existing high tension systems • Standard mechanical connection: M10, M14 and M18

Open the catalog to page 11

Gas Fired Igniters Tube 054 mm Ignition of main burners in furnaces, boilers, power plants and incinerators Features and Benefits • High energy ignition • Insensitive to moisture • Stainless steel construction • Self-aspirating, forced air supply or combination • For self-aspirating version no air supply line required • Insensitive to pressure fluctuations • Robust design • For all kind of gases and pressures • Integrated spark plug(s) and ionisation electrode • Explosion proof version (ATEX) available Applications • Main burners of furnaces, boilers, incinerators and power plants...

Open the catalog to page 12All DURAG Group catalogs and technical brochures

-

Dust Monitor for Wet Stacks

4 Pages

-

D-LL 7XX Fibre optic systems

4 Pages

-

7813 | 7814 Diffusion dryer

2 Pages

-

Aerosol Neutralizers

4 Pages

-

ProCeas® H2 purity analyzer

2 Pages

-

ProCeas® ATEX/IECEx

2 Pages

-

Emission Monitoring

24 Pages

-

D-LX 110

6 Pages

-

D-LX 201

6 Pages

-

D-EMS 2020

6 Pages

-

D-ZL

1 Pages

-

D-HG 400, D-HG 500

1 Pages

-

brochure accessories

8 Pages

-

D-LX 200

4 Pages

-

D-LX 201/721

6 Pages

-

D-LX 100

1 Pages

-

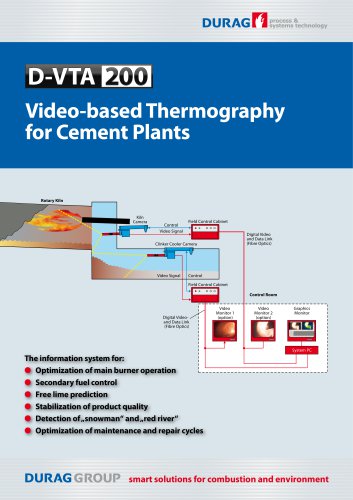

D-VTA 200 Cement

4 Pages

-

D-HG 500

4 Pages

-

Product overview

12 Pages

-

DURAG data systems data CEMS

12 Pages

-

DURAG Traffic Sensors

2 Pages

-

HEGWEIN Accessories

8 Pages

-

HEGWEIN Gas Burners

16 Pages

-

HEGWEIN Gas Fired Igniters

20 Pages

-

HEGWEIN Oil Guns

8 Pages

-

HEGWEIN Oil Fired Ignitors

12 Pages

-

SMITSVONK Products

24 Pages