Website:

DURAG Group

Website:

DURAG Group

Group: Durag Group

Catalog excerpts

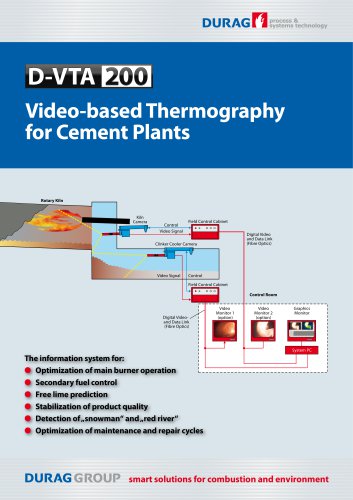

Video-based Thermography for Cement Plants Drehrohrofen Rotary Kiln Kiln OfenCamera kamera Steuerung Control Videosignal Video Signal Feldschaltschrank Field Control Cabinet Digital Video Digitaler Videoand Datenlink und Data Link (Fibre Optics) (Glasfaser ) Klinkerkühlerkamera Clinker Cooler Camera Videosignal Video Signal Steuerung Control Feldschaltschrank Field Control Cabinet Control Room Digitaler VideoDigital und Datenlink and Data Link (Glasfaser ) (Fibre Optics) Video VideoMonitor 1 monitor 1 (option) Leitstand Video VideoMonitor 2 monitor 2 (option) Graphics GrafikMonitor monitor The information system for: ● Optimization of main burner operation ● Secondary fuel control ● Free lime prediction ● Stabilization of product quality ● Detection of „snowman“ and „red river“ ● Optimization of maintenance and repair cycles smart solutions for combusti

Open the catalog to page 1

Video Monitoring The D-VTA 200 video and thermography system The thermography analyzing system is a modular system specially developed for use in the cement industry, to monitor the clinker manufacturing process. Intelligent sensors allow contactless, optical and thermal online analysis of processes in the sinter zone in rotary kilns and in clinker coolers. ●● pneumatically operated retraction system with monitoring units for the cooling and flushing media, including integrated air accumulator ●● Field control cabinet for control of the sensors, operation of the optional spectrometers and...

Open the catalog to page 2

Analysis System ●● Measurement of the flame and clinker temperatures (reference) ●● Assessment of the thermal influence of the main burner flame on the burning process (radiation behaviour and temperature transition). Technical data ●● Free lime prediction from correlation of spectroscopy data and process data (DURAG patent). This prediction indicates the process trend sensitively and at an early stage, providing the possibility of process optimization. Video system PAL, picture elements: 752(H) x 582(V), fixed focus Thermography from total radiation Optical alignment Sensor 0°:...

Open the catalog to page 3

DURAG UK SMITSVONK Netherlands DURAG France DURAG GROUP Germany DURAG Italy DURAG India DURAG China DURAG Japan DURAG Korea DURAG Brazil ©DURAG GROUP 11/2011 · Subject to change without notice DURAG Niederlassung Süd Weidenweg 16 73087 Bad Boll, Germany Tel. +49 7164 912 25-0 Fax +49 7164 912 25-50 E-Mail: DURAG-Sued@durag.de DURAG Niederlassung West An der Pönt 53a 40885 Ratingen, Germany Tel. +49 2102 74 00-0 Fax +49 2102 74 00 28 E-Mail: DURAG-West@durag.de International DURAG, Inc., USA 1355 Mendota Heights Road · Suite 200 Mendota Heights · MN 55120, USA Tel. +1 651 451-1710 Fax +1 651...

Open the catalog to page 4All DURAG Group catalogs and technical brochures

-

Dust Monitor for Wet Stacks

4 Pages

-

D-LL 7XX Fibre optic systems

4 Pages

-

7813 | 7814 Diffusion dryer

2 Pages

-

Aerosol Neutralizers

4 Pages

-

ProCeas® H2 purity analyzer

2 Pages

-

ProCeas® ATEX/IECEx

2 Pages

-

Emission Monitoring

24 Pages

-

D-LX 110

6 Pages

-

D-LX 201

6 Pages

-

D-EMS 2020

6 Pages

-

D-ZL

1 Pages

-

D-HG 400, D-HG 500

1 Pages

-

brochure accessories

8 Pages

-

D-LX 200

4 Pages

-

D-LX 201/721

6 Pages

-

D-LX 100

1 Pages

-

D-VTA 200 Cement

4 Pages

-

D-HG 500

4 Pages

-

Gas Fired Igniters

24 Pages

-

Product overview

12 Pages

-

DURAG data systems data CEMS

12 Pages

-

DURAG Traffic Sensors

2 Pages

-

HEGWEIN Accessories

8 Pages

-

HEGWEIN Gas Burners

16 Pages

-

HEGWEIN Gas Fired Igniters

20 Pages

-

HEGWEIN Oil Guns

8 Pages

-

HEGWEIN Oil Fired Ignitors

12 Pages

-

SMITSVONK Products

24 Pages