Catalog excerpts

Group 1 – PUMPS Group 2 - PRESSURE CONTROL VALVES Group 3 - FLOW CONTROL VALVES Group 4 - DIRECTIONAL VALVES Group 5 - SUBPLATES AND MANIFOLDS Group 6 - MODULAR VALVES Group 7 – ACTUATORS Group 8 - PROPORTIONAL VALVES Group 8 - ELECTRONIC CONTROL UNITS Group 9 - ACCESSORIE

Open the catalog to page 1

EXTERNAL GEAR PUMPS SERIES 20 OPERATING PRINCIPLE — The GP pumps are fixed displacement external gear pumps with axial clearance compensation. — They give high volumetric efficiency even with high operating pressures, a low noise level, and they have a high endurance thanks to the balancing system of the loads on the guide bushings. — They are divided into three size groups, with displacements of up to 9,1 - 27,9 and 87,6 cm3/rev respectively, and with operating pressures of up to 250 bar (standard) and up to 310 bar (version for high pressures H). — They are available with clockwise,...

Open the catalog to page 2

SERIES 20 1 - IDENTIFICATION CODE 1.1 - Identification code for single and front pumps External gear pump Pump size: H = version for high pressures. Omit for standard pressure. Seals: N = NBR seals for mineral oils omit for single pumps (standard) F = only for front pump to be coupled Series No. (from 20 to 29 sizes and mounting dimensions remain unchanged) Nominal size (see table 3 - Performances) Hydraulic connection F = flanged ports (standard) B = BSP threaded ports U = UNF threaded ports Rotation direction (seen from the shaft side) R = clockwise (standard) L = anticlockwise D =...

Open the catalog to page 3

SERIES 20 1.3 - Identification code for multiple pumps identification code front pump identification code intermediate pump (omit for double pumps) identification code rear pump 1.4 - Compatibility among mounting flange, type of shaft and type of hydraulic connection FLANGE CODE 9 SHAFT CODE 1.5 - Identification code for mating joints FIRST PUMP HYDRAULIC CONNECTION CODE SECOND PUMP a) single pump size 1 - 1,3 cm 3/rev - anticlockwise rotation - standard flange and shaft GP1-0013L97F/20N b) single pump size 2 - 14 cm 3/rev - clockwise rotation - standard flange and shaft GP2-0140R97F/20N c)...

Open the catalog to page 4

2.3 - Degree of fluid contamination The maximum degree of fluid contamination must be according to ISO 4406:1999 class 20/18/15; therefore, use of a filter with β20 ≥75 is recommended. A degree of maximum fluid contamination according to ISO 4406:1999 class 18/16/13 is recommended for optimum endurance of the pump. Hence, use of a filter with β10 ≥100 is recommended. If there is a filter installed on the suction line, be sure that the pressure at the pump inlet is not lower than the values specified in paragraph 13. The suction filter must be equipped with a by-pass valve and, if possible,...

Open the catalog to page 5

SERIES 20 4 - CURVES AND CHARACTERISTIC DATA OF GROUP GP1 PUMPS (values obtained with mineral oil with viscosity of 36 cSt at 50°C) 4.1 - Flow rate curves Q=f (n) obtained with operating pressure 0 bar PUMP NOMINAL SIZE VOLUMETRIC EFFICIENCY [%] TOTAL EFFICIENCY [%] 4.3 - Noise level PUMP NOMINAL SIZE The volumetric and total efficiencies for the various nominal dimensions of the Group GP1 pumps, measured at 1500 rpm and with 150 bar operating pressure, are shown in the table. The total efficiency considers the volumetric efficiency and the mechanical efficiency of the pump in the specified...

Open the catalog to page 6

4.4 - Absorbed power curves N=f (n), measured with operating pressures from 50 to 250 bar

Open the catalog to page 7

SERIES 20 5 - CURVES AND CHARACTERISTIC DATA OF GROUP GP2 PUMPS (values obtained with mineral oil with viscosity of 36 cSt at 50°C) 5.1 - Flow rate curves Q=f (n) Q [l/min] obtained with operating pressure 0 bar PUMP NOMINAL SIZE VOLUMETRIC EFFICIENCY [%] TOTAL EFFICIENCY [%] The volumetric and total efficiencies for the various nominal dimensions of the Group GP2 pumps, measured at 1500 rpm and with 150 bar operating pressure, are shown in the table. The total efficiency considers the volumetric efficiency and the mechanical efficiency of the pump in the specified operating conditions. 5.3...

Open the catalog to page 8

5.4 - Absorbed power curves N=f (n), measured with operating pressures from 50 to 250 bar

Open the catalog to page 9

SERIES 20 6 - CURVES AND CHARACTERISTIC DATA OF GROUP GP3 PUMPS (values obtained with mineral oil with viscosity of 36 cSt at 50°C) 6.1 - Flow rate curves Q=f (n) obtained with operating pressure 0 bar VOLUMETRIC EFFICIENCY [%] TOTAL EFFICIENCY [%] PUMP NOMINAL SIZE The total efficiency considers the volumetric efficiency and the mechanical efficiency of the pump in the specified operating conditions. The volumetric and total efficiencies for the various nominal dimensions of the Group GP3 pumps, measured at 1500 rpm and with 150 bar operating pressure, are shown in the table. 6.3 - Noise...

Open the catalog to page 10

6.4 - Absorbed power curves N=f (n), measured with operating pressures from 50 to 250 bar

Open the catalog to page 11

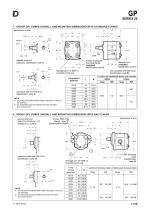

SERIES 20 7 - GROUP GP1 PUMPS OVERALL AND MOUNTING DIMENSIONS WITH STANDARD FLANGE dimensions in mm tapered shaft end (standard, identification code 7) 10 ø12 drainage port 1/4” BSP on reversible pump only pump nominal dimension cylindrical with key shaft end (identification code: 5) NOTE: 1. On pumps with anticlockwise rotation the ports (1) and (2) are reversed 2. On reversible pumps the delivery port has the same size of the suction 4 holes rectangular mounting flange (standard, identification code 9) flanged ports (standard, identification code F) also available with BSP ports...

Open the catalog to page 12

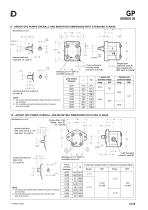

SERIES 20 9 - GROUP GP2 PUMPS OVERALL AND MOUNTING DIMENSIONS WITH STANDARD FLANGE dimensions in mm 12 tapered shaft end (standard, id. code 7) drainage port 1/4” BSP on reversible pump only 90 pump nominal dimension cylindrical with key shaft end (id code: 5) NOTE: 1. On pumps with anticlockwise rotation the ports (1) and (2) are reversed 2. On reversible pumps the delivery port has the same size of the suction 4 holes rectangular mounting flange (standard, id.code 9) flanged ports (standard, code F) also available with BSP ports id.code B) 1 suction port clockwise rotation flange BSP Ø13...

Open the catalog to page 13All Duplomatic Oleodinamica catalogs and technical brochures

-

Energy eng

4 Pages

-

PZM2

2 Pages

-

IGP INTERNAL GEAR PUMPS

20 Pages

-

1P EXTERNAL GEAR PUMPS

4 Pages

-

GP - External gear pumps

16 Pages

-

Mobile eng

3 Pages

-

Industrial eng

5 Pages

-

Machine tool eng

6 Pages

-

Metal forming eng

6 Pages

-

Mobile eng

2 Pages

-

Leaflet Axes Control System

2 Pages