Catalog excerpts

RADIAL DRIVEN TOOL SYSTEM WITH DIRECT MOTOR TURRETS TECHNICAL INFORMATION The data given in the IT. are subject to technical modifications without notice.

Open the catalog to page 1

RADIAL DRIVEN TOOL TURRET The new DM-TR radial driven tool turrets have been developed strictly applying the Value Engineering technique, taking benefits of design similarity, reduced number of components and common parts, for a lean mechanical design. Advanced technology and modern solution for heavy duty CNC Turning Centers. TURRET • Based on the last generation ; 180 Drive DM design (patented). 10 Direct • Hydraulic clamping system. • High stiffness and accuracy. • High loading capacity. DRIVEN TOOL SYSTEM • New lean mechanical design, based on the original, patented and well known...

Open the catalog to page 3

DM-TR * / series 10 TECHNICAL DATA Turret Tool stations one step index time step-less rotation time (Tsb) Unclamping or (Tb) Clamping time Positioning times: Inertia of transportable masses Indexing frequency Indexing accuracy Repeatibility accuracy Working pressure Electric supply - Inputs / Outputs Mass (complete system without driven tool motor) Ambient temperature range • Costant flow • Pressure cut-off during turret rotation Coolant supply : Standard : (Filtering ≤ 100 µm) (1) Larger inertia values can be applied with increased indexing times (2) Conditions: • Hydraulic supply properly...

Open the catalog to page 4

DM-TR* / series 10 TECHNICAL DATA Tool drive Transmission ratio Coupling (4) These values are valid for free-shock operations. In case of interrupted-cut or other shock-operations, a reduction of these values up to 50% must be considered. Size Siemens A.C. Motor — Max speed Fanuc A.C. Servomotor — Torque — Max speed Fanuc A.C. Spindle motor — Torque (5) Servomotor with "orientation function" by CNC must be used. (6) Other motors on request. INDICATIVE CUTTING CAPACITY for 600 N/mm2 steel, HSS tools (With fit motors) Twist drilling Slot milling

Open the catalog to page 5

SIZES AND TOOLING LAY-OUT NEW BMT TOOLING SYSTEM • Size range from 45 to 75. • 4 bolts fitting system to maximize cutting rigidity. • 2 keys and centering diameter reference system to reach the best positioning accuracy. • Oversize tenon coupling to grant high torque and power transmission. Disc size Indicative tool swing Matching DM-TR turret size

Open the catalog to page 6

SIZES AND TOOLING LAY-OUT DIN 69880 traditional TOOLING SYSTEM • Size range from 25 to 50. • Tenon coupling DIN 1809. • Same rotating toolholders of axial ODT-N driven tool system. Disc size Indicative tool swing Matching DM-TR turret size

Open the catalog to page 7

HOUSING MORPHOLOGY STANDARD • Front machining only • Same height as stand-alone DM turrets • Same foot print as stand-alone DM turrets BM1 • Front and back-machining • Same height as stand-alone DM turrets • Foot print "compatible" with stand-alone DM turrets BM2 • Front and back-machining • Same height as SM-BR driven turrets • Foot print "compatible" with SM-BR driven turrets

Open the catalog to page 8

TURRET AND DISC VERSIONS BMT TOOLING LEFT TURRET RIGHT TURRET NOTE: The BMT tool disc is always the same. Tool disc WORKING POSITION: • STANDARD: at "3 o'clock" for right turrets. at "9 o'clock" for left turrets. • Different working positions, on request.

Open the catalog to page 9

ROTATING TOOLHOLDERS SPECS BMT TOOLING SYSTEM • Coupling specs L DM-TR size • Tool disc seats protection Housing not engaged with toolholders must be properly plugged: Plugs supplied with the disc Additional cover (not supplied) Housing engaged with static toolholders must be properly plugged: Plugs supplied with the disc • Tool clamping – It is recommended to clamp the tools with two wrenches. The use of one only wrench causes damages the driven tool center module. – This plate is supplied with the DM-TR turret, and it must be fitted on the machine so as to be very clearly seen.

Open the catalog to page 10

ROTATING TOOLHOLDERS SPECS DIN 69880 TOOLING SYSTEM • Coupling specs DIN 1809 C DM-TR size • Angular adjusting pins on disc (for radial rotating units) • Tool clamping – It is recommended to clamp the tools with two wrenches. The use of one only wrench causes damages the driven tool center module. – This plate is supplied with the DM-TR turret, and it must be fitted on the machine so as to be very clearly seen. – Housing not engaged with toolholders must be properly plugged (DIN 69880 Shape Z2).

Open the catalog to page 11

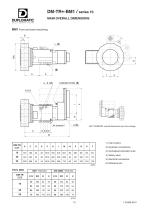

MAIN OVERALL DIMENSIONS FRONT Machining only B U LEFT VERSION: overall dimensions are mirror-image DM-TR SIZE TOOL DISC DM-TR SIZE 2) Hydraulic connections. 3) Centralized lubrication inlet. 4) Safety valve. 5) Electrical connectors. 6) Reference pin.

Open the catalog to page 12

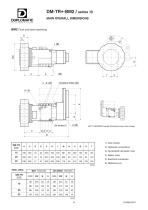

DM-TR*-BM1 / series 10 MAIN OVERALL DIMENSIONS LEFT VERSION: overall dimensions are mirror-image DM-TR SIZE TOOL DISC DM-TR SIZE 2) Hydraulic connections. 3) Centralized lubrication inlet. 4) Safety valve. 5) Electrical connectors. 6) Reference pin.

Open the catalog to page 13

DM-TR*-BM2 / series 10 MAIN OVERALL DIMENSIONS LEFT VERSION: overall dimensions are mirror-image DM-TR SIZE TOOL DISC DM-TR SIZE 2) Hydraulic connections. 3) Centralized lubrication inlet. 4) Safety valve. 5) Electrical connectors. 6) Reference pin.

Open the catalog to page 14

DM-TR* / series 10 HYDRAULIC DIAGRAM HYDRAULIC POWER PACK (Example) (1) IMPORTANT: A flow adjustment valve must be foreseen in order to avoid a violent or noisy clamping. (2) The accumulator's volume is according to the real pump flow rate. Needed instant flow [l/m] Clamping turret Unclamping turret DN recommended nominal diameter for hydraulic line ≤6m

Open the catalog to page 15

CENTRALIZED LUBRICATION SYSTEM The DM-TR turret has been preset with a lubrication function, that can be used in order to prevent wearing increasing due to heavy driven tool duty cycle. Metering valve (not supplied) Lubrication drain – Lubrication supply: • Type of lubricant : Oil with viscosity ≤ 750 cSt (40°) or fluid grease. WARNING: If oil contamination inside the working area is not allowed, please contact our Technical Dept.

Open the catalog to page 16