Catalog excerpts

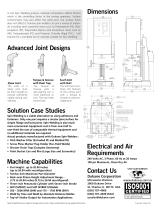

Spin Welder Model SVB031 & 051 Spin Welding Process and Advantages Spin Welders use the heat generated by rotational friction at the joint line to weld thermoplastic parts. The machine applies pressure axially while rotating one part against its stationary mate and the resulting friction generates heat that melts the parts together. Advantages of the spin welding process include — • high–quality permanent joints • hermetic seals • ease of assembly • immediate handling • lower equipment costs • energy efficient operation • no ventilation required • entrapment of other parts, • far–field welding capability and • no additional material requirements Applications Features • • • • • • • • • • • • • • • 3 and 5 HP Direct Drive Models Computer–Controlled Motor Digital RPM Settings Dynamic Braking Option 13.7 x 16.5 inch (347 x 419mm) Fixture Tooling Platen Digital Timer Sets Weld and Hold Times Keypad Programmer with Backlit 2–Line LCD Display Industry–Standard Logic and Motor Controllers Pneumatic Thruster Adjustable Column Height Adaptable to Automation Applications Ultra–Rigid Square Support Column Factory Installed Lifting Eye Ergonomic Base with Status Indicators Dual Palm Switches with Abort complies with International Safety Standards Intelligent Assembly Solutions Spin Welders have diverse applications: Automotive industry for parts such as filters, floats, check valves, pipes, fittings, fixtures and housings. Medical applications include blood–processing equipment, chemical pumps, fittings flow meters and IV drug delivery. Consumer Product applications include thermal mugs, insulating liners, storage containers, microwave ovenware and appliance components. Industrial applications include conveyor systems, gears, pulleys, couplings and motor housings. Spin welders are also used in the Toy Manufacturing and Sporting Goods industry.

Open the catalog to page 1

In the Spin Welding process, material composition affects friction which is the controlling factor in the joining operation. Surface contaminants may also affect the weld joint, but surface finish does not affect it. Dukane spin welders can join a variety of materials including semi–crystalline resins such as Polyethylene (PE), Polypropylene (PP), Polyamides (Nylon) and amorphous resins such as ABS, Polycarbonate (PC) and Polyvinyl Chloride (Rigid PVC). Call Dukane for a complete list of materials suitable for Spin Welding. Advanced Joint Designs inches (millimeters) WITH SPECIAL FACTORY...

Open the catalog to page 2All Dukane Intelligent Assembly Solutions catalogs and technical brochures

-

VWB4900

2 Pages

-

ServoWeld Plus Spin Welder

2 Pages

-

VWB4500 - Vibration Welder

2 Pages

-

VWB4300 - Vibration Welder

2 Pages

-

VW5960LPT - Vibration Welder

4 Pages

-

VW5900 - Vibration Welder

2 Pages

-

VW5700LPT - Vibration Welder

2 Pages

-

VW5700 - Vibration Welder

2 Pages

-

VW5500 - Vibration Welder

2 Pages

-

VW5300 - Vibration Welder

2 Pages

-

Corrugated Plastic Welders

2 Pages

-

Medical Solutions

4 Pages

-

Vibration Welding

4 Pages

-

Laser Welder Handout

2 Pages

-

Ultrasonic Food Processing

2 Pages

-

Ultrasonic Welders Brochure

4 Pages

-

Vibration Welding Brochure

4 Pages

-

VWB4900 - Vibration Welder

2 Pages

-

EZ-Welder

2 Pages

-

VWB3500 - Vibration Welder

2 Pages

-

VWB3700 - Vibration Welder

2 Pages

-

Thermal Probe

2 Pages

-

20 kHz Sealed Transducer

2 Pages

-

Thermal Press

2 Pages

-

UFF-2 40 kHz mini-slitter

2 Pages

-

UFF-1 Sonic Slitter

2 Pages

-

VW 5500 Vibration welder

2 Pages

-

VW 5700 Vibration Welder

2 Pages

-

VW5900 Vibration Welder

2 Pages

-

VWB4500 Vibration Welder

2 Pages

-

VWB4700 Vibration Welder

2 Pages

-

VWB4700LPT Vibration Welder

2 Pages

-

VWB4900 Vibration Welder

2 Pages

-

Standard Sound Enclosure

2 Pages

-

ultrasonic press system

4 Pages

-

Dukane Vibration Welding

4 Pages

Archived catalogs

-

Model 3700 Vibration Welder

2 Pages

-

Model 3500 Vibration Welder

2 Pages

-

Medical Device Assembly

4 Pages

-

Ultrasonic Welders

4 Pages