Catalog excerpts

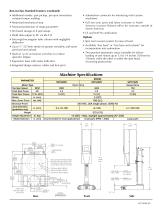

Intelligent Assembly Solutions DUAL SERVO SPIN WELDERS Color touch-screen with intuitive menu controls. Dukane’s Dual ServoWeld Spin Welder is designed for welding circular parts that have a tight tolerance requirement for both the orientation between the parts being welded and the overall final welded assembly height. The new design builds on the solid foundation of Dukane’s existing single servospin welder, by replacing the pneumatic Z-axis drive with a second servomotor. The unit’s control system has resolutions of 0.1 degrees for rotation and .0004 in. (.01 mm) for Z-axis position. In addition, the control system coordinates the performance of both servomotors thereby providing the user with a new welding technology Dukane calls Melt Match. The Melt Match technology uses a constant torque welding mode in which the welder automatically adjusts the Z-axis speed to match the melt rate of the material for a specified spin torque. A user friendly color touch screen operator interface is standard. Setup of machine is virtually effortless thanks to the position jog teach feature. This intuitive interface allows the operator to quickly and simply jog the unit to both the final orientation axis position and the final Z-axis height position. Error conditions are graphically indicated on the panel and include an explanation of the source of the error. All machine setup parameters are programmed through the password-protected interface. This insures that no unauthorized adjustment of the machine setup can occur. A programmable feature also allows the user to define the “home” position, thereby allowing the elimination of unnecessary vertical stroke and thereby reducing overall cycle time. The machine can store up to eight setup files in local memory, and has programmable limits on up to 11 independent process parameters. All weld data can be exported via RS-232 data port. Best-in-Class Standard Features • Large color touch screen with intuitive menu structure • High precision servo spin drive with orientation resolution of 0.1 degree • Servo vertical actuator with positioning resolution of .0004 in. (.01 mm) • Trigger by vertical position or spin torque • Programmable welding methods include Weld by Time, Rotations, Collapse Distance w/orientation, Absolute Distance w/orientation, and Energy. • Post weld features include Hold by Time (constant speed or thrust) and Hold by Collapse Distance, with optional Static Hold. • Up to 11 independent programmable upper and lower part limits allow for advance process control www.dukcorp.com/us • e-mail: ussales@dukcorp.com ...continued on back Page Dukane Corporation • Ultrasonics Division • 2900 Dukane Drive • St. Charles, Illinois 60174 USA • TEL (630) 797-4900 • FAX (630) 797-4949

Open the catalog to page 1

Best-in-Class Standard Features (continued) • Additional modes: part pickup, pre-spin orientation, constant torque welding • Automation connector for interfacing with custom machinery • Motorized mechanical stop • Full two-year parts and labor warranty in North America (contact Dukane office for warranty outside of North America) • Password protection of setup parameters • On board storage of 8 part setups • Weld data output to PC via RS-232 • Extra-rigid rectangular tube column with negligible deflection • Spin tool vacuum system for ease of load. • Available “less base” or “less base and...

Open the catalog to page 2All Dukane Intelligent Assembly Solutions catalogs and technical brochures

-

VWB4900

2 Pages

-

ServoWeld Plus Spin Welder

2 Pages

-

VWB4500 - Vibration Welder

2 Pages

-

VWB4300 - Vibration Welder

2 Pages

-

VW5960LPT - Vibration Welder

4 Pages

-

VW5900 - Vibration Welder

2 Pages

-

VW5700LPT - Vibration Welder

2 Pages

-

VW5700 - Vibration Welder

2 Pages

-

VW5500 - Vibration Welder

2 Pages

-

VW5300 - Vibration Welder

2 Pages

-

Corrugated Plastic Welders

2 Pages

-

Medical Solutions

4 Pages

-

Vibration Welding

4 Pages

-

Laser Welder Handout

2 Pages

-

Ultrasonic Food Processing

2 Pages

-

Ultrasonic Welders Brochure

4 Pages

-

Vibration Welding Brochure

4 Pages

-

VWB4900 - Vibration Welder

2 Pages

-

EZ-Welder

2 Pages

-

VWB3500 - Vibration Welder

2 Pages

-

VWB3700 - Vibration Welder

2 Pages

-

Thermal Probe

2 Pages

-

20 kHz Sealed Transducer

2 Pages

-

Thermal Press

2 Pages

-

Spin Welder - SVB031-SVB051

2 Pages

-

UFF-2 40 kHz mini-slitter

2 Pages

-

UFF-1 Sonic Slitter

2 Pages

-

VW 5500 Vibration welder

2 Pages

-

VW 5700 Vibration Welder

2 Pages

-

VW5900 Vibration Welder

2 Pages

-

VWB4500 Vibration Welder

2 Pages

-

VWB4700 Vibration Welder

2 Pages

-

VWB4700LPT Vibration Welder

2 Pages

-

VWB4900 Vibration Welder

2 Pages

-

Standard Sound Enclosure

2 Pages

-

ultrasonic press system

4 Pages

-

Dukane Vibration Welding

4 Pages

Archived catalogs

-

Model 3700 Vibration Welder

2 Pages

-

Model 3500 Vibration Welder

2 Pages

-

Medical Device Assembly

4 Pages

-

Ultrasonic Welders

4 Pages