Catalog excerpts

Ductile Cast Iron Gate Valves for water and gas supply

Open the catalog to page 1

Reliable, Dependable and Economical Ductile cast iron valves In Germany alone, thousands of kilometers of pipes Cast iron is a natural material and forms the basis ensure a reliable supply of water, anytime and of the Düker valves. Due to its outstanding mate- rial properties, it complies 100% with the following requirements: The piping used needs to meet the highest require- • Long service life ments: • High density • Resistance to intense soil movement • Excellent corrosion resistance • Reliability even after many service years • Economic efficiency • Securing of perfect hygiene • Safe...

Open the catalog to page 2

Materials of Düker gate valves Material Type 2004/4004 DN 80 – 200 Sealing wedge Sealing wedge Sealing wedge Cylinder head screws Cylinder head screws Cylinder head screws Bonnet seal Bonnet seal Clamping piece Screening ring Screening ring Retaining ring Sliding ring Sliding disc Edge protection Edge protection Operating media and test pressures medium test pressure in bar test medium water body seat test medium air/gas seat seat PG 2 PG 3

Open the catalog to page 3

A safe connection living up to its promise Another important element for a safe and above all • Düker SMU and leak-proof pipeline is its connections. • Düker SPEZIAL for screwed sockets • TYTON® SIT® and In addition to the tried and tested flange connections, • TYTON SIT PLUS® for TYTON® sockets Düker also offers, depending on the application area, • NOVO-SIT® and socket systems with the corresponding thrust resist- • NOVO-Grip® III for Novo sockets ing joints for an axial-restraint connection. Etec enamel – the special surface protection for valves Etec enamel is a composite material which...

Open the catalog to page 4

Gate Valves 2004, 4004 and 4014 Completely with shock-resistant enamelling for best possible corrosion protection and 100% hygiene Area of application: Drinking water • as per EN 1171 and EN 1074 part 1+2 • EPDM vulcanized wedge and gasket Area of application: Gas/waste water • NBR vulcanized wedge and gasket Corrosion protection • ody inside and outside with b complete and seamless shockresistant enamelling as per the DEV guideline (soil class III, • with complete epoxy powder or coating as per GSK directives in blue (RAL 5005) for potable water or yellow (RAL 1023) for gas Type 4004...

Open the catalog to page 5

turns open/ close Gate valve face-to-face dimension according to EN 558 basic series 15

Open the catalog to page 6

Gate Valve 4004 with PE 100 Pipe Ends Gate Valve 4004 with PE 100 Pipe Ends for welding – area of application water for welding – area of application gas The innovative valve series for the application The innovative valve series for the application Corrosion protection with plastic pipes with plastic pipes The standard version of the gate valve is equipped with a high quality epoxy powder coating according Area of application water to the RAL-GZ 662 quality assurance of the “Güte- gemeinschaft schwerer Korrosionsschutz (GSK)”, • For all gases according to DVGW publication the German...

Open the catalog to page 7

PE 100 pipe welding studs (black for water and gas) with stainless steel support sleeve. For welding in PE pipelines applying the heating element butt welding method. Pipe length laid out for two welding processes. Testing according to DIN 3230-5 PG 2 or PG 3; including 3.1 B certificate according to EN 10204. Dimensions and weights D mm Wall thicknesses of PE pipes as per DIN 8074

Open the catalog to page 8

Replacement and Repair Gate Valve 2004 and 4004 The perfect valve for the application in pipe trenches Area of application water Cam lock Thrust resisting joint • as per EN 1171 and EN 1074 part 1+2 • For drinking and untreated water up to PN 10/16 The loose flanges can be drawn out within a toler- Flange sealing Loose flange ance range of 4 mm on each side. In addition, their connection to the valve body is fully restrained. • Ambient temperature up to +60 °C • For all plant and pipeline network operators The elimination of the old flange gaskets provides an additional tolerance, which is...

Open the catalog to page 9

Gate Valve 4004 with Blow-off Pipes The perfect valve for modern gas distribution systems – with simple and fast gas ventilation Area of application gas • For all gases according to DVGW publication G 260/I Inspection report: Engler-Bunte-Institute regardVP 600, melting index group MFI 005 and 010, according to the guidelines of the DVGW publica- ing connection technology on the basis of DVGW- • It is used for retrofits or new construction of PE gas pipelines in the pressure range ≤ PN 4 The most important elements PE 100 pipe ends for welding. The gate valve with blow-off pipes is equipped...

Open the catalog to page 10

Gate Valve 3004 with Steel Pipe Ends for Welding Shock-resistant enamel on the inside and “PUR” polyurethane coating on the outside – the perfect solution for gas supply Area of application gas • For all gases according to DVGW publication G 260/I with PG 3 pressure test Gate valve type 3004 Resilient seated with a smooth passage according to EN 13774. Body and bonnet in EN-GJS-400-18 with shoed ends from St. 35.8 edge form 22. Wedge Corrosion protection with new guidance, vulcanized plastic sliding shoes. Enamel on the inside pursuant to the DEV guideline (except Stem made of stainless...

Open the catalog to page 11

More than 500 Years of Experience in Iron Casting Our know-how for your benefit Quality on the highest possible level The Düker name has been synonymous for premium Our long-standing tradition is what you can benefit We are the first to set the highest requirements for the quality of our products. quality iron casting for more than 500 years. We from. All of our qualified teams in engineering, sales, And, as a result, we have introduced a certified modern quality management are today among the leading manufacturers of production and service are happy to assist you with system according to...

Open the catalog to page 12All Düker GmbH catalogs and technical brochures

-

fitting and valves

164 Pages

-

Thrust Resisting Joints

10 Pages

-

Stem Extension Sets

2 Pages

-

Tapping Valve Type TOP 1014

6 Pages

-

Survey of Butterfly Valves

9 Pages

-

Survey of Hydrants

9 Pages

-

Valve Brochure

8 Pages

-

Fittings Brochure

12 Pages

-

WASSERSPIEGEL

20 Pages

-

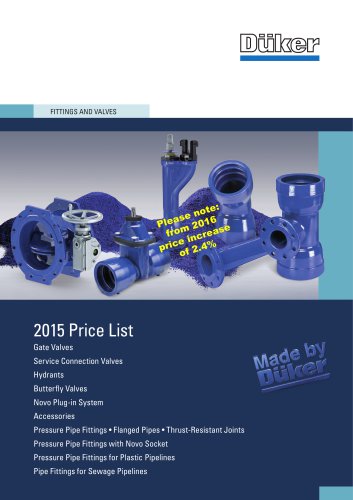

2015 Price List

119 Pages

-

Bottom Outlet Valves

7 Pages

-

Loose flange connection

2 Pages

-

Glass lined columns

4 Pages

-

BAV

3 Pages

-

TE

11 Pages

-

E series

7 Pages

-

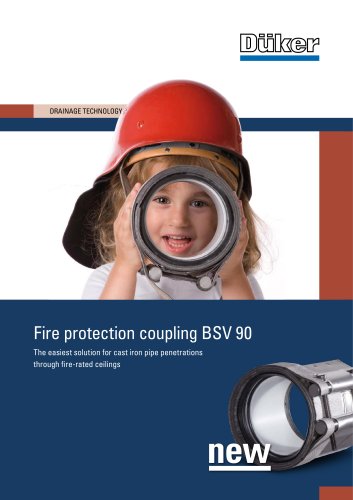

BSV 90

5 Pages