Website:

ds automation gmbh

Website:

ds automation gmbh

Catalog excerpts

dsound Acoustic Sensor Technology made in Germany Tap CheckEmpty bottle inspection in the food industry Tap Check The Tap check system spots damaged or flawed glass containers and provides for following rejection. This acoustic method is ideal, especially with regard to hair crack detection. Tap Check is established at the filling line and monitors each and every bottle. With an output of 72.000 bottles per hour, this system is designed for automated, industrial use. Tap Check stands out positively from alternative methods with respect to price. www.schallsensor.de/en 4£> 2013 dtt autination gm*hi

Open the catalog to page 1

Tap Check Tap Check is a system consisting of an air-borne sound sensor, a photo sensor and a mechanic excitation unit. The latter uses a position-controlled titanium clapper combined with high-performance signal processing. An air-borne sound sensor processes the created tone whereat a defined frequency points to glass breakage or cracks. The system emits a relevant bad-signal in order to reject flawed bottles. It can be connected with a rejection system via CAN Bus. It should be pointed out that the detection of hair cracks with alternative measuring principles is impossible. Without...

Open the catalog to page 2All Ds automation gmbh catalogs and technical brochures

-

Tap Check Complete solution

1 Pages

-

Cap Check Complete solution

1 Pages

-

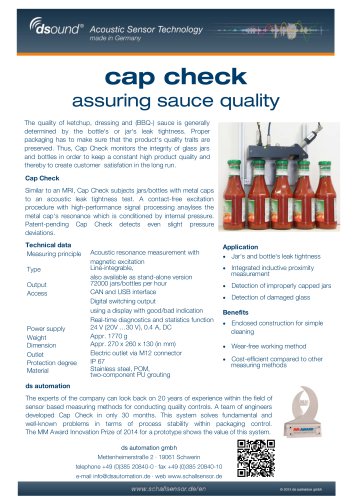

Cap Check Sauces

1 Pages

-

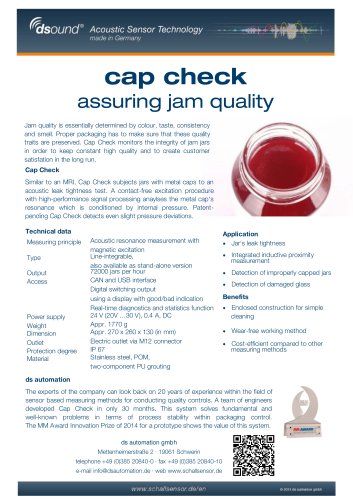

Cap Check Jam quality

1 Pages

-

Cap Check Beer quality

1 Pages

-

Cap Check Baby food

1 Pages

-

Data sheet dsound® USE01

2 Pages

-

Sound sensors dsound® series

2 Pages

-

Data sheet dsound® ALC1

2 Pages

-

dsound® application

2 Pages