Website:

ds automation gmbh

Website:

ds automation gmbh

Catalog excerpts

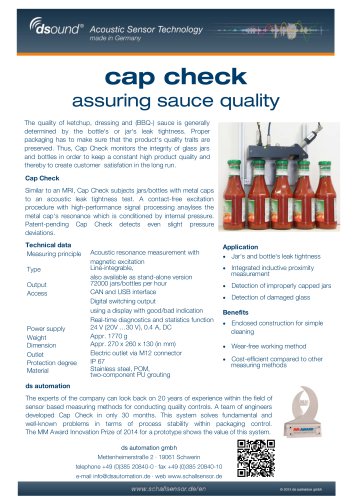

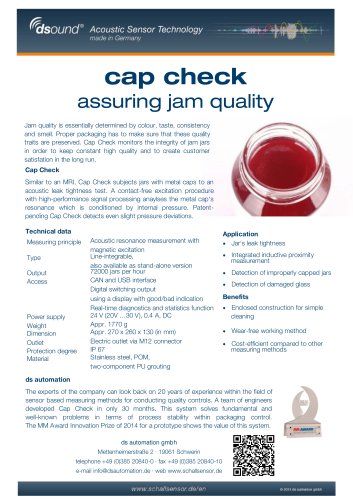

dsouncT Acoustic Sensor Technologymade in Germany cap check — assuring beer quality The beer market is characterized by high quality and hygiene standards. For industrial players, conducting permanent tests is a must in order to meet the requirements for taste, smell, colour, quantity, cleanliness, the froth‘s texture, and even the sound when opening the bottle. Cap Check assists to maintain a constant high quality level of beer using innovative acoustic sensor technology. Thus, a higher customer satisfaction is created in the long run. Similar to an MRI, Cap Check subjects beer bottle caps to an acoustic leak tightness test. A contact-free excitation procedure with high-performance signal processing analyses the crown cap‘s resonance which is conditioned by internal pressure. Patent-pending Cap Check detects pressure differences in the range of only 0.1 bar. The system tracks leaky bottles reliably, even in filling lines without pasteurization. Technical data Measuring principle Type Output Access Power supply Weight Dimension Outlet Protection degree Material Acoustic resonance measurement with magnetic excitation Bottling-line integrable also available as stand-alone solution 72000 bottles per hour CAN and USB interface Digital switching output using a display with good/bad indication Real-time diagnostics and statistics function 24 V (20 V ... 30 V), 0.4 A, DC Appr. 1770 g Appr. 270 x 260 x 130 (in mm) Electric outlet via M12 connector IP 67 Stainless steel, POM, two-component PU grouting Application • Pressure test and leak tightness test • Integrated inductive proximity measurement • Detection of improperly capped/sealed bottles • Detection of missing caps and seals • Detection of broken bottles and damages Benefits • Enclosed construction for simple cleaning • Wear-free working method • Cost-efficient compared to other measuring methods ds automation The experts of the company can look back on 20 years of experience within the field of sensor based measuring methods for conducting quality controls. A team of engineers developed Cap Check in only 30 months. This system solves fundamental and well-known problems in terms of process stability within packaging control. The MM Award Innovation Prize of 2014 for a prototype shows the value of this system. ds automation gmbh MettenheimerstraBe 2 • 19061 Schwerin telephone +49 (0)385 20840-0 • fax +49 (0)385 20840-10 e-mail info@dsautomation.de • web www.schallsensor.de www. schallsensor. de/en O 2013 ds autmation gmb

Open the catalog to page 1All Ds automation gmbh catalogs and technical brochures

-

Tap Check Complete solution

1 Pages

-

Cap Check Complete solution

1 Pages

-

Cap Check Sauces

1 Pages

-

Cap Check Jam quality

1 Pages

-

Cap Check Baby food

1 Pages

-

Data sheet dsound® USE01

2 Pages

-

Sound sensors dsound® series

2 Pages

-

Data sheet dsound® ALC1

2 Pages

-

dsound® application

2 Pages