Website:

Druseidt

Website:

Druseidt

Catalog excerpts

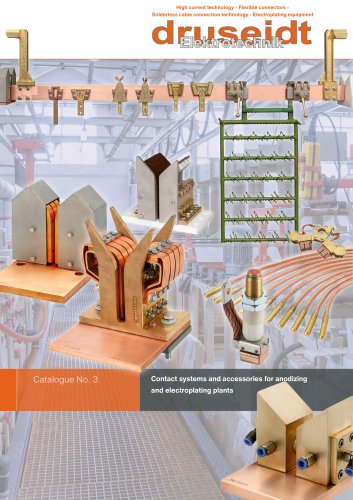

Contact-Systems and Accessories for Anodising and Electroplating Equipment

Open the catalog to page 1

Description Page High Current Contacts and Accessories for Rack Systems Contact Saddles - Standard Contact Saddles - Two Piece Model Contact Saddles - with Integrated Guides High Current Bolt Contacts Pneumatic Contacts Pneumatic Contacts Pneumatic Contacts with Moveable Contact Fingers Work Rods, Bimetallic Sheets and Washers Bolting Blocks Anodes and Small Contact Saddles Contact Saddles with Spring and Stamped Contact Plates Contact Saddles Bar supports - Metal and Plastic Contacts for Galvanising Racks Rack Contact Holders 20 Cam Levered Rack Contacts 21 Wing Screws and Nuts...

Open the catalog to page 2

Factory View Neuenkamper Strasse Factory View Lenneper Strasse Aerial photograph of our factory P. Druseidt Elektrotechnische Spezialfabrik GmbH & Co. KG Neuenkamper Strasse 105 · 42855 Remscheid · Germany P.O. Box 10 02 25 · 42802 Remscheid · Germany Phone +49 (21 91) 93 52-0 · Fax +49 (21 91) 93 52-150 E-Mail: verkauf@druseidt.de · Internet: www.druseidt

Open the catalog to page 3

Quality and constructive know-how backed by modern production technology ... Quality Products ... provide the user with a wide range of contacts and current transfer elements, fine tuned to the respective requirements.

Open the catalog to page 4

High Current Contacts for Galvanising Equipment Much emphasis is being placed on the quality of finishing and plating galvanising and electroplating. These increasing requirements are simultaneously combined with the demands for inexpensive methods and rational, low-maintenance production procedures. Every component of a plating system must therefore be equipped to meet these prerequisites. Weak points which can be the cause for repairs or system down-time or that could lead to plating problems must be avoided or eliminated. A major prerequisite for optimal processing is that the current...

Open the catalog to page 5

High Current Contactors for Work Rod Systems High Current –Contact Saddles 250 - 3000 A One Piece Standard Version A proven druseidt contact system for decades. Technically up-to-date and continuously under development. Supplied either as one piece standard contact for a bus-bar thickness of 10/15 or 20 mm or as a ready-to-install contact unit complete with base, i.e., integrated power connection bar or angle and insulation plate. Contacts with base are suitable for immediate installation on the tank frame. In order to maximize the life-span of the contacts and to minimize repair and down...

Open the catalog to page 6

High Current Contact Saddles 250 - 3000 A One Piece Standard Version Part No. Part No. Part No. Contact block Contact block 1 set Replacement complete with base contact elements. max. Prefabricated load Number Suitable of contact bus-bar fingers Dimensions mm B B, H H, S S, Weight kg/item. without base Accessories/Replacement Parts 50732 1 Piece installed mounting guide Part No. 30690 Replacement spring - Stainless steel, Standard 17198 Replacement foil, Type - 2 Fold Part No. 30691 Replacement spring - Stainless steel, Heavy Version 17199 Replacement...

Open the catalog to page 7

High Current Contact Saddles 4000 – 14000 A Two Piece Model The 4000 A and up range, proven for many years. The standard version is supplied as a contact pair, i.e. delivered in two non connected halves. This allows the contacts to be set individually according to the bus-bar thickness for installation. The installation distance of the contact halves must be less than the thickness of the bus-bar (depending on the contact block or weight of the bus-bar 4 – 6 mm; consultation required). Inserting the busbar works with the bar’s own weight which makes these contacts very efficient for fully...

Open the catalog to page 8

High Current Contact Saddles 4000-14000 A Two Piece Model Part No. Part No. Part No. Number Contact block Contact block 1 set Replacement Suitable of contact complete with base contact elements max. bus-bar fingers Prefabricated load height mm 15 x 12 mm L B, Weight kg/piece without base Part No. 30691 Replacement spring - Stainless steel, Heavy version Part No. 30692 Replacement spring - Stainless steel, Heavy duty version Accessories/Replacements 30702 1 Piece installed mounting guide 17198 Replacement foils, Type - 2 fold 17199 Replacement foils, Type - 3 fold Note: All...

Open the catalog to page 9

High Current Contact Saddles 250 - 4000 A One Piece Model with Integrated Guides This range of contacts is a further development based on our standard version. The construction of the contact finger has been modified with an easy exchange foil package which in cases decreases the size of the unit. Furthermore, guides have been integrated directly in the main module on each side. Besides technical improvements, this also creates an overall less expensive solution as well. These contacts are delivered as a one piece model for bus-bar thickness 10, 15 or 20 mm. Although the installation size...

Open the catalog to page 10

High Current Contact Saddles 250 - 4000 A One Piece Model with Integrated Guides Part No. Part No. Part No. Weight Contact block Contact block 1 set Replacement Suitable Number kg/piece complete with base contact elements, max. bus-bar of contact Dimensions mm without Prefabricatedload height mm fingersL L1 B H ^ S S1base Replacements 30690 Replacement spring - Stainless steel, Normal Version 30691 Replacement spring - Stainless steel, Heavy Version Note: All contacts for a bus-bar thickness up to 20 mm are delivered as a one piece module. For heavier bars, the...

Open the catalog to page 11

High Current Bolt Contacts 1000 - 12000 A With Spring Fed Contact Bolts druseidt System druseidt High Current Bolt Contacts consist of two equal contact halves that are fixed together. These are configured for the required bus-bar thickness before delivery. For bus-bar thickness over 10 mm, respective spacing elements are utilised. The current transfer is made over several points on the spring fed E-Cu contact bolts with a beryllium disk. The amount and layout of the contact bolts depends on the desired current load and the height of the bus-bar. Inserting the bus-bar is performed using the...

Open the catalog to page 12All Druseidt catalogs and technical brochures

Archived catalogs

-

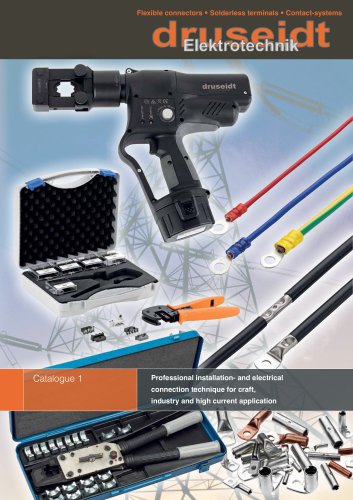

Battery powered crimping tool

12 Pages