Catalog excerpts

EDDY CURRENT SEPARATOR TECHNICAL CHARACTERISTICS Inductor Drum: • Maximum Versatility and Durability Our Eddy Current Separators with eccentric rotor are designed to extend the equipment's lifespan and prevent breakdowns, optimizing your plant's performance. With the option to manufacture the rotor with different pole configurations, they can efficiently separate large, medium, and small fractions of aluminum with precision. A versatile and reliable solution for all your recycling needs! Rotor configured with different number of poles depending on the grain size of the aluminium to be separated. Eccentricity up to 135 mm. Magnetic intensity at contact: 5KGauss. Main shaft made of F127, detachable. Neodymium magnets mechanically locked and secured with threecomponent glass resin. Outer drum made of 7 mm thick glass resin. Standard bearing supports from FAG SKF brand. Enclosed bearings are maintenance-free (sealed). External bearings with automatic SKF greaser. Protective guards for the belt and drums made of 2 mm shiny stainless-steel sheet. Product separation tray made of stainless steel. Main structure made of 8 mm formed sheet steel. Product discharge hood made of 8 mm carbon steel. Product discharge hopper made of 4 mm sheet steel. Side inspection and cleaning windows for the separator tray. The tray can move along the Y-Z axes and rotate angularly via sliders. Rotor transmission motor from 5 to 11 kW Siemens. Rotor speed up to 2900 rpm. Belt drive transmission. Conveyor belt motor drum from 2.2 to 4 kW Rulmeca. Belt speed up to 2.5 m/sec. Conveyor belt: • • Polyurethane or rubber belt, anti-static and grease-resistant. Scraper mounted on the lower p

Open the catalog to page 1All Drago Electrónica catalogs and technical brochures

-

Magnetic Palletiser

1 Pages

-

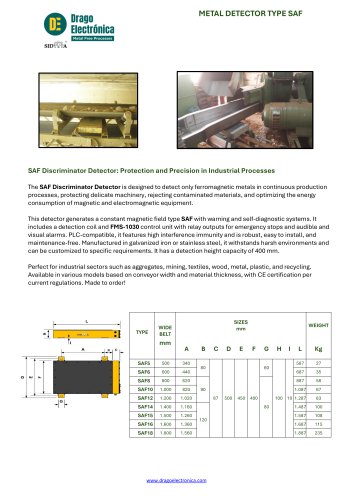

Metal detector type SAF

1 Pages

-

Metal detector type GRS

1 Pages

-

Metal detector type SIF

1 Pages

-

Metal detector type ERS

1 Pages

-

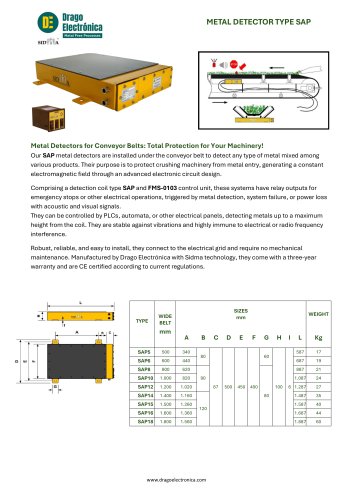

Metal detector type SAP

1 Pages

-

MAGNETIC PULLEY

4 Pages

-

MAGNETIC SEPARATION

16 Pages