Catalog excerpts

Dosing and filling systems SYSTEM PROVIDER selection of our special A projects in the eccentric screw pump range multi Eccentric screw pump with follower plate Barrel emptying plant Bottling plant Component Filling and Dosing System Dispensing of small quantities made easily

Open the catalog to page 1

General requirements for dosing Precision in dosing Numerous customers from the food sector, as well as the packaging and chemical industries want to decant liquids not only from barrels or containers, but to fill these precisely in small containers. In the case that thin to viscous media should be volumetrically filled into small containers, in addition to a gentle and low-pulsation delivery an accurate dosing is imperative. Component Filling and Dosing System Structure of Multi-Component Filling and Dosing System The metering system is integrated in a frame of stainless steel SS 316 Ti...

Open the catalog to page 2

Multi-Component Filling and Dosing System The input of the recipes and dosing batch is done via an elegant display with a keyboard. In order to ensure process safety, the changing of parameters and recipes are protected by a password. Frequency inverter (in central control cabinet) indicator Level Control cabinet with digital display Central, password-protected control cabinet in a separate room switch for starting Foot the dosing Multi-Component Filling and Dosing System For dispensing of low-viscosity to medium viscosity medias according to specified recipes a Multi-Component...

Open the catalog to page 3

Multi-Component Filling and Dosing System / Dosing pumps for liquid to viscous media of dosing a minimal amount of product in the dispensing nozzle sucked back, therefore a filling valve will not be needed. The input of the recipes with the dosing of the individual components is done via an input display, which is housed in a central control cabinet. The central control cabinet, is due to the customer‘s specifications, in a separate room. In order to ensure process safety, the changing of parameters and recipes is only possible by password and therefore protected from changes. Another...

Open the catalog to page 4

Mobile single-column barrel emptying plant Lift me up, lift me up higher and higher Electric or pneumatic powered lifting devices are used in many industries for lifting and positioning heavy supplies. In connection with an eccentric screw pump, also barrels with highly viscous media can be emptied quickly, safely and semi-automated. Numerous customers from the bottling, manufacturing or packaging industry need to empty highly viscous liquids from a variety of 200 liter barrels quick, clean and as simple as possible. In many of these applications, it is no longer enough for a pump...

Open the catalog to page 5

Mobile single-column barrel emptying plant Mobile Single-Column Barrel Emptying Plant for a semi-automated emptying of four barrels on a pallet pump is also equipped with a follower plate with rubber sealing lip, which allows virtually residue-free emptying of barrels. However, an essential prerequisite for the use of such barrel emptying plant are cylindrical and especially undamaged barrels, in which the sealing lip of the follower plate, the inner wall of the barrel wipe clean. In the present case, the customer often get damaged and dented barrels delivered. Dented barrels can ultimately...

Open the catalog to page 6

Mobile single-column barrel emptying plant and controls Mobile Single-Column Barrel Emptying Plant Operating methodes and controls By pressing and holding the key „PumpDOWN“, the lifting device is unlocked and lowered the pump by means of the pneumatic cylinder to the exhaust position in the barrel. After reaching the end position of the emptying process is started by pressing the „Pump ON“. Due to the ease of use and design of the single-column barrel emptying plant the transfer procedure must be monitored only by one person. Once the barrel is empty and the pump sucks air, the liner is...

Open the catalog to page 7

Eccentric screw pump with follower plate Stationary Single-column Barrel emptying Plant Starting point for the stationary single-column barrel emptying plant with follower plate were again the own eccentric screw pumps. Operating Principle This additional special construction by JESSBERGER was delivered to a customer, who wanted to fill a high-viscosity preservative agent from 200 liter barrels by means of a type grease gun with follower plate and a scale in small containers. By means of a double-acting pneumatic cylinder the pump is lifted into the upper end position. The barrel to be...

Open the catalog to page 8

Eccentric screw pump with follower plate residue in the barrel amount is about 1% of the barrel volume. By means of lift cylinder the pump with follower plate is lifted into the upper end position. The pneumatically operated vent valve (pinch), mounted on the follower plate, will supply compressed air from about 0.5 bar between barrel base and follower plate. The resulting lifting force transports the eccentric screw pump as far out from the barrel until the follower plate has reached the barrel edge. Then the vent valve is shut off. Operation of the barrel emptying plant by keypad Button...

Open the catalog to page 9

Bottling plant with hopper Bottling Plant with hopper with manual feed of the bottles, cups or cans Another plant with a funnelshaped storage container for filling in bottles, cups or cans also bases upon the principle of eccentric screw pumps. To start the filling process initially a trial issue is to calibrate. This is done by entering the nominal capacity and the determined actual amount of the sample output. Then the continuous filling can begin. Occasional checks to deviations of capacity from the nominal value are required. Any discrepancies can be corrected manually at the control...

Open the catalog to page 10

Bottling plant with hopper The bottling plant was completely made of stainless steel SS 316 Ti and is thus suitable for many industries and applications. In addition to chemical resistance with respect to the conveying medium, care was taken in the design of the plant with regards to the compatibility with respect to any cleaning agents as well as the expected temperatures in the cleaning process. The bottling plant can be used both in stand-alone mode as well as be involved operated in a master control unit and allows in this particular case of the customer a valveless, subsequent dripping...

Open the catalog to page 11All Dr. Jessberger GmbH catalogs and technical brochures

-

CENTRIFUGAL PUMPS

16 Pages

-

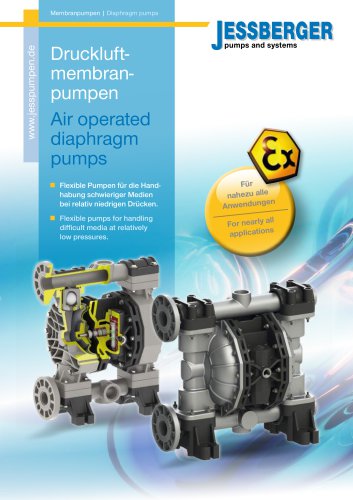

AIR OPERATED DIAPHRAGM PUMPS

12 Pages

-

ECCENTRIC SCREW PUMPS

12 Pages

-

HAND PUMPS

8 Pages

-

DRUM AND CONTAINER PUMPS

8 Pages

-

PRODUCT OVERVIEW

12 Pages