Catalog excerpts

Cleaners Remove Silicone Deposits from Industrial Equipment and Surfaces Case Study: Dow Corning® DS-2025 Silicone Cleaning Solvent and Dow Corning® DS-1000 Aqueous Silicone Cleaner PROJECT Demonstrate the removal of cured and uncured silicone from substrates. PRODUCTS Dow Corning ® DS-2025 Silicone Cleaning Solvent Dow Corning ® DS-1000 Aqueous Silicone Cleaner Silicones are widely used in various products and in manufacturing processes, and good cleaning practices can help you reduce the risk of microbial or chemical contamination in finished products, reduce the likelihood of buildup-related equipment failures, and contribute to good industrial hygiene and worker safety. Dow Corning offers two products for the easy removal of silicone deposits on tools, kettles, bottling lines, pipes, manufacturing equipment, floors and other surfaces: Dow Corning ® DS-2025 Silicone Cleaning Solvent for removing cured silicones and Dow Corning ® DS-1000 Aqueous Silicone Cleaner for removing uncured silicones. Using Dow Corning ® DS-2025 Silicone Cleaning Solvent to remove cured silicone To demonstrate the cleaning effect of Dow Corning ® DS-2025 Silicone Cleaning Solvent, a plastic pipe was coated with Dow Corning ® RSN-0749 Resin – a curable silicone that, on evaporation of the cyclomethicone, forms a cured film of highmolecular-weight silicone resin. The silicone was applied to the outside of the pipe rather than the inside (Figure 1) so the cleaning can be seen more effectively. The pipe was left to stand in Dow Corning ® DS-2025 Silicone Cleaning Solvent overnight at room temperature (Figure 2). It was then rinsed with water and dried to yield a clean pipe (Figure 3). Recommended procedure for using Dow Corning ® DS-2025 Silicone Cleaning Solvent to remove cured silicone from industrial equipment: 1. Silicone digestion - Drain tanks and lines from a maximum of residue and water (0.5% maximum). - Fill tanks and lines with Dow Corning ® DS-2025 Silicone Cleaning Solvent. - Ventilation is required. A nitrogen blanket is not required but may be used as an additional safety measure if working at 60°C. - Recirculate Dow Corning ® DS-2025 Silicone Cleaning Solvent at room temperature (or up to 60°C) until dissolution of residue is effective. Typically, this takes one to four hours. - Note that no impact of Dow Corning ® DS-2025 Silicone Cleaning Solvent on stainless steel 304 and 316 has been detected. Additionally, no impact has been detected on Teflon®, Viton®, nitrile, polyethylene, polypropylene or EPDM gaskets, seals and joints, as well as ABS and PET. However, Dow Corning ® DS-2025 Silicone Cleaning Solvent will affect nylon, butyl rubber, polyurethane … continued on back and silicone gasket

Open the catalog to page 12. Degreasing - Drain Dow Corning® DS-2025 Silicone Cleaning Solvent from unit and refill container for next use. - Start CIP cleaning with 10% Dow Corning® DS-1000 Aqueous Silicone Cleaner to solubilize and remove solvent residue. 3. Sanitization - Perform final sanitization according to customer standard practice. Using Dow Corning® DS-1000 Aqueous Silicone Cleaner to remove uncured silicone To demonstrate the cleaning effect of Dow Corning® DS-1000 Aqueous Silicone Cleaner, some XIAMETER® PMX-200 Silicone Fluid, 350 CS - a typical uncured silicone - was poured onto a floor (Figure...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

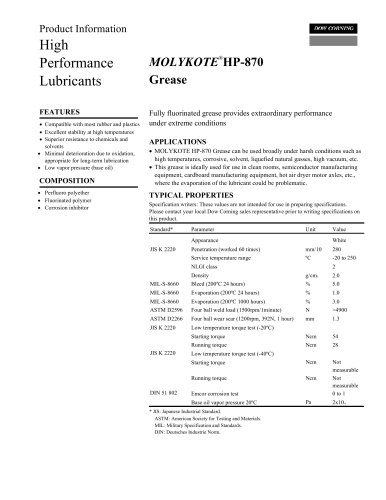

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages