Catalog excerpts

Silicone Resins and Intermediates Selection Guide

Open the catalog to page 1Innovative Technology 3 The Chemistry of Silicone Resins 4 Selecting a Resin Binder System 5-6 Choosing a Silicone Resin 7-9 Dow Corning® brand Resins: Typical Properties • Solvent-Based Resins • Flake Resins • Alkoxy Resins and Intermediates 10 Other Formulation Components 11 Product Information and Technical Support 11 Important Information on Storage, Handling and Flammability Discover Innovative Technology The use of silicon-based technologies in the coatings market has evolved over the decades, allowing formulators to create differentiated, high-performance protective and decorative...

Open the catalog to page 2The Chemistry of Silicone Resins Silicone resins are polymers comprised of a siloxane (silicon–oxygen) lattice with at least some portion comprised of the silicate (SiO4/2) or silsesquioxane (R-SiO3/2) structures, where R represents various alkyl or aryl organic groups (most commonly methyl or phenyl). In comparison to organic resins (with their carbon-carbon backbone), silicone resins exhibit greater resistance to thermal and radiation degradation. The durability of silicone resins is attributed to the bond strength between silicon and oxygen (108 vs. 82.6 kcal/mole for the carbon-carbon...

Open the catalog to page 3Selecting a Resin Binder System The first step in creating a coating prototype is to define the application performance demands and the potential resin binder system. Thermal, chemical and radiation exposure along with required cure schedule and needed physical properties all influence the choice of resin binder. While silicone resin will contribute to the paint’s thermal, chemical and UV radiation resistance, some performance attributes and physical properties will benefit from combinations of silicone and organic binders. • Hardness: Phenolics and melamines • Air-dry: Acrylics • Corrosion...

Open the catalog to page 4Choosing a Silicone Resin Dow Corning offers a diverse line of silicone resins and resin intermediates. Solvent-based, solventless liquid and solid flake options are available, allowing formulators to meet a wide range of performance and regulatory requirements and to achieve the best balance of performance, compliance and economy. dioxide ash reacts with pigments and fillers to create the metalo-silica composite, which provides long-term thermal stability – but this attribute must be balanced with other film properties, particularly flexibility. Figures 1 and 2 provide the means by which...

Open the catalog to page 5Figure 2: Decision Tree for Selecting a Dow Corning® brand Resin FDA-Regulated Application? Si-Organic Hybrid? Dow Corning ® RSN-0255 Flake Resin Cold Blend Dow Corning ® RSN-0217 Flake Resin Powder Coating? High Hardness Needed? Dow Corning ® RSN-0220 Flake Resin Dow Corning ® RSN-6018 Resin Intermediate Dow Corning ® RSN-0255 Flake Resin Dow Corning ® RSN-0249 Flake Resin Cold Blend Cold Blend Si-Organic Hybrid? Si-Organic Hybrid? Dow Corning ® RSN-6018 Resin Intermediate No Dow Corning ® RSN-0806 Resin Dow Corning ® RSN-0805 Resin

Open the catalog to page 6Solvent-Based Resins from Dow Corning Dow Corning delivers silicone resin solutions that can be used alone, or in combination with organic resins or other silicone resins. They vary in resin content, organic compatibility and molecular weight, allowing formulators to design coatings to meet specific application requirements: • High-temperature coatings where low VOC content is required • Maintenance paints for improved UV durability • Colored baking enamels for wood-burning stoves, space heaters, etc. • As an additive to improve the flow-out and initial gloss of epoxy coatings Table 2:...

Open the catalog to page 7Flake Resins from Dow Corning Dow Corning® flake resins deliver silicone technology concentrated in dry, pourable flakes, which can either be solvated or used as neat polymers in powder coatings or composites or combined with “softer” solvated silicone resins to improve hardness and reduce VOCs. The flakes also can be cold-blended or copolymerized with organic polymers to improve thermal and weathering resistance. • High-temperature powder coatings for barbecue grills • Mica board composites • Ceramic firings • Silicone-alkyd copolymers for protective and marine paint • Silicone-polyester...

Open the catalog to page 8Alkoxy Resins and Intermediates from Dow Corning The unique reactivity of the silylalkoxy group provides this class of materials with a broad array of utility in the coatings market. • “Polysiloxane” epoxy and acrylate hybrid topcoats • Reacted with unsaturated polyesters, oil-free alkyds and other hydroxyl-bearing organic resins for flexible, weather-resistant coil coatings • Dow Corning® RSN-5314 Resin is used for modification of acrylic and other alkaline pH resin emulsions • Silicone-polyester copolymers made with Dow Corning® 3074 Intermediate are suitable for applications regulated by...

Open the catalog to page 9Other Formulation Components Catalysts Silanol-functional resins will heat-cure without the addition of catalyst, but the addition of metallic driers (e.g., zinc, iron or cobalt octoate) will accelerate the rate of cure. Typical catalyst level is 0.1 to 0.2% metal on resin solids. Dow Corning RSN-0805 Resin, Dow Corning RSN-0806 Resin and Dow Corning RSN-0808 Resin are supplied pre-catalyzed. Silylalkoxy resins require the addition of hydrolysis catalysts (e.g., tetrabutyltitanate [TBT] or tetraisopropyltitanate [TiPT]). Typical use level is 0.5% on resin solids. Leaching of metals (e.g.,...

Open the catalog to page 10Important Information on Storage, Handling and Flammability Storage and shelf life Dow Corning silicone resins should be stored at room temperature in sealed containers, away from heat and open flame. Dow Corning solid flake products should be stored below 22°C (72°F). Refer to individual products’ technical data sheets or contact Dow Corning for the shelf life (from date of manufacture) of the Dow Corning resins and intermediates discussed in this brochure. Handling precautions Product safety information required for safe use is not included. Before handling, read product and safety data...

Open the catalog to page 11All Dow Corning catalogs and technical brochures

-

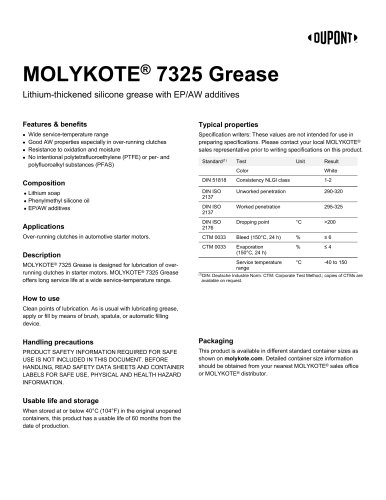

MOLYKOTE® 7325 Grease

2 Pages

-

MOLYKOTE® 7325 Grease

2 Pages

-

Molykote ® Z Powder

2 Pages

-

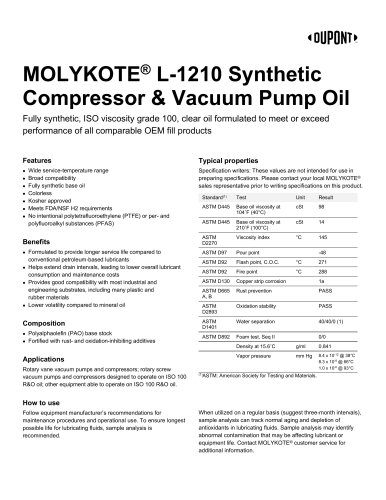

MOLYKOTE® L-1210 Synthetic

2 Pages

-

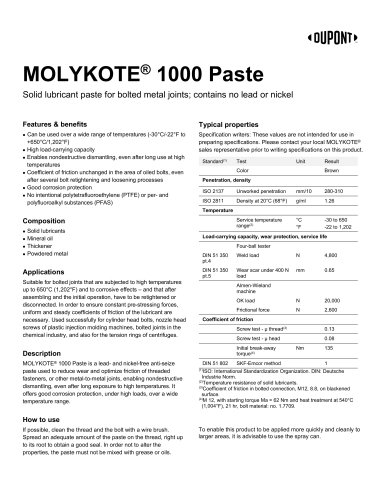

MOLYKOTE® 1000 Paste

2 Pages

Archived catalogs

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

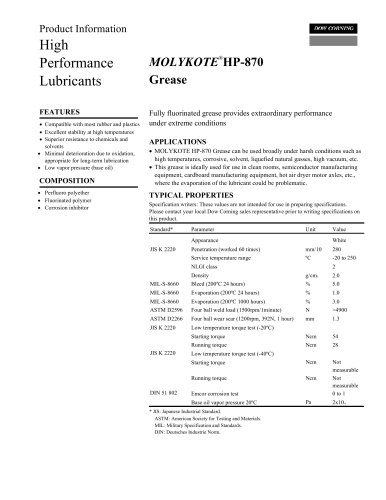

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

-

Molykote® Industrial Lubricants

52 Pages