Catalog excerpts

An Overview of Polydimethylsiloxane (PDMS) Fluids in the Environment Environmental Information - Update Health Environment & Regulatory Affairs (HERA) Environmental Entry: Most polydimethylsiloxane fluids are non-volatile polymeric organosilicon materials consisting of -(CH3)2SiO- structural units. Due to the wide range of applications for PDMS fluids, they can enter the environment in a variety of ways. Since they are non-volatile, they do not evaporate into the atmosphere. In household products, very small amounts of PDMS fluids may be washed from the surfaces to which they’ve been applied and eventually into the soil or a wastewater treatment plant (WWTP). typically, n > 4* Various PDMS fluids ranging from low to high viscosity are used in a wide range of industrial applications, such as manufacturing textiles, paper, and leather goods1. In these industries, PDMS fluids are highly-efficient process aids, able to provide desirable properties at very low concentrations. They often serve as antifoams, softeners, or water repellents. In consumer applications, PDMS fluids can be found in personal-, household- and automotive care products.1 They are used as softeners in skin care products, conditioners in hair care, additives in polish formulations, waterproofers and as a component of other surface treatments. Some PDMS materials are also sold as end products (usually in the industrial market), such as transformer dielectric fluids and heat transfer liquids. For example, personal care products such as shampoos and conditioners are rinsed away after use, and the PDMS they contain is carried with wastewater to the treatment site. This could be a private septic system or municipal plant. When PDMS fluids are used in industrial applications such as process aids or surface treatments, small quantities can also be found in process wastewater that is carried to the treatment plant. Of the total PDMS production volume worldwide, about 17% is used in “down-the-drain” applications. End-use industrial products such as transformer fluids are used in contained applications. These are suitable for recycling and are therefore unlikely to enter the environment except in cases of accidental release. * Materials with n=4 or less are referred to as VMS (volatile methylsiloxane) Ref. n° 01-1034A-01 © Copyright Dow Corning Corp., 1997. All rights reserved.

Open the catalog to page 1

An Overview of Polydimethylsiloxane (PDMS) Fluids in the Environment Environmental Information - Update Health Environment & Regulatory Affairs (HERA) Environmental Fate and Effects: The fate of PDMS is partly a function of where it enters the environment. A number of studies have shown that PDMS will degrade into lower molecular weight compounds, primarily Me2Si(OH)2, when in contact with soils. 2-6 Testing under a variety of representative conditions has confirmed the observation in a wide range of different soils, 4 indicating that the phenomenon is widespread in nature. Bioconcentration...

Open the catalog to page 2

An Overview of Polydimethylsiloxane (PDMS) Fluids in the Environment Environmental Information - Update Health Environment & Regulatory Affairs (HERA) solids, sludge volume index, and specific oxygen uptake) or physiological activity of the microflora in the model activated sludge units. Sludge digestion operating parameters (suspended solids, gas generation, pH) were also unaffected by loadings of up to 100 mg/kg of PDMS.21 The ultimate fate of sludge-bound PDMS depends on the sludge disposal technique. If the sludge is incinerated, the silicone content converts to amorphous silica, which...

Open the catalog to page 3

An Overview of Polydimethylsiloxane (PDMS) Fluids in the Environment Environmental Information - Update 10. RR. Buch, T.H. Lane, R.B. Annelin, C.L. Frye, “Photolytic Oxidative Demethylation of Aqueous Dimethylsiloxanols,” Environmental Toxicology and Chemistry, 3, 215 (1984). 11. R. Atkinson, “Kinetics of the Gas-Phase Reactions of a Series of Organosilicon Compounds with OH and NO3 Radicals and Ozone at 297 ± 2K,” Environmental Science and Technology 25, 863 (1991). 12. R. Somerlade, H. Parlar, D. Wrobel, R Kochs, “Product Analysis and Kinetics of the Gas Phase Reactions of Selected...

Open the catalog to page 4All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

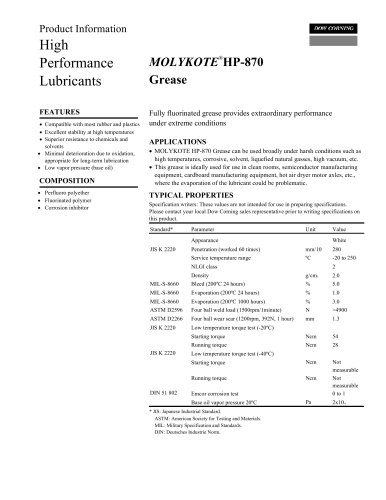

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages