Catalog excerpts

Product Information Specialty Lubricants FEATURES & BENEFITS Excellent lubricating properties Reduction of friction and wear Resistant to oxidation Extreme pressure resistance Wide service temperature range COMPOSITION Molybdenum disulphide Molykote® Z Powder Solid Lubricant APPLICATIONS Molykote® Z Powder can be used: as a dry burnished (rubbed-on) lubricating film for metallic contacts as a solid lubricant additive for self-lubricating plastics and sinter metal parts as a solid lubricant additive in metalworking compounds as a solid lubricant additive in brake lining application as run-in aid, in press-fittings, in Heavy Loads and Slow Speeds applications and also in extreme environments (for example in dusty atmospheres or extremes of temperatures) TYPICAL PROPERTIES Specification Writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product. Test* Property Color Consistency Purity (MoS2 content) Particle size distribution (Laser Method Malvern Mastersizer in 2-propanol) Particle size (Fisher Method) Service temperature range Service temperature range (in vacuum) Theoretical density (solid state) Bulk density (powder state) Water/moisture content Almen Wieland machine OK load Press-Fit test *CTM: Corporate Test Method, copies of CTMs are available on request. ISO: International Organization for Standardization. Molykote® Z Powder is a solid lubricant that lubricates metal surfaces in many difficult and extreme environments e.g. metal/metal pairings at extreme loads and slow speeds, or metal/plastic pairings at low loads and low to medium speeds. Rub the powder thoroughly in different directions on degreased dry surfaces using a hard brush or window leather. Can be applied by rotary brush, felt or polishing disks. Small parts should preferably be tumble coated. Add to plastic elastomers and sinter metals before forming.

Open the catalog to page 1

HANDLING PRECAUTIONS PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERIAL SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS AVAILABLE ON THE DOW CORNING WEBSITE AT DOW CORNING.COM, OR FROM YOUR DOW CORNING SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CORNING CUSTOMER SERVICE. USABLE LIFE AND STORAGE When stored at or below 20°C (68°F) in the original unopened bags, this product has a usable life of 60 months from the date of...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

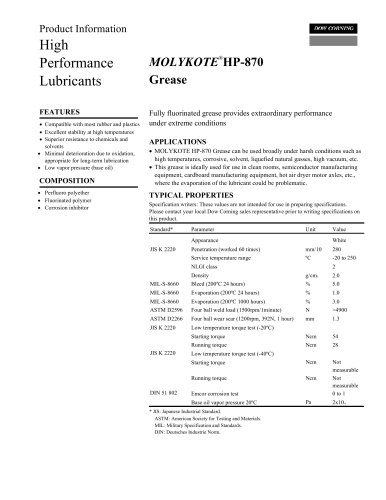

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages