Catalog excerpts

Product Information Industrial Maintenance Wide Service Temperature Range Broad Compatibility Fully Synthetic Base Oil Colorless Kosher Approved Meets FDA/NSF H2 Requirements BENEFITS • Formulated to provide longer service life compared to conventional petroleum-based lubricants • Helps extend drain intervals leading to lower overall lubricant consumption and maintenance costs • Provides good compatibility with most industrial and engineering substrates including many plastic and rubber materials • Lower volatility compared to mineral oil COMPOSITION • Polyalphaolefin (PAO) base stock • Fortified with Rust & Oxidation inhibiting additives Molykote® L-1210 Synthetic Compressor & Vacuum Pump Oil Fully synthetic, ISO viscosity grade 100, clear oil formulated to meet or exceed performance of all comparable OEM fill products APPLICATIONS • Rotary vane vacuum pumps and compressors • Rotary screw vacuum pumps and compressors designed to operate on ISO 100 R&O oil • Other equipment able to operate on ISO 100 R&O oil TYPICAL PROPERTIES Specification Writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product. Test* D 445 D 445 D 2270 D 97 D 92 D 92 D 130 D 665 A,B D 2893 D 1401 D 892 Property Base Oil Viscosity at 104˚F (40˚C) Base Oil Viscosity at 210˚F (100˚C) Viscosity Index Pour Point Flash Point, C.O.C. Fire Point Copper Strip Corrosion Rust Prevention Oxidation Stability Water Separation Foam Test, Seq II Density at 15.6˚C Vapor Pressure CTM: Corporate Test Method, copies of CTM’s are available on request. HOW TO USE Follow equipment manufacturer’s recommendations for maintenance procedures and operational use. To ensure longest possible life for lubricating fluids, sample analysis is recommended. When utilized on a regular basis (suggest three month intervals), sample analysis can track normal aging and depletion of antioxidants in lubricating fluids. Sample analysis may identify abnormal contamination that may be affecting lubricant or equipment life. Contact Dow Corning customer service for additional information.

Open the catalog to page 1

HANDLING PRECAUTIONS Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The material safety data sheet is available on the Dow Corning website at dowcorning.com. You can also obtain a copy from your local Dow Corning sales representative or Distributor or by calling your local Dow Corning Global Connection. USABLE LIFE AND STORAGE When stored at or below 40°C (104°F) in the original unopened containers, this product has a usable life of 60 months...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

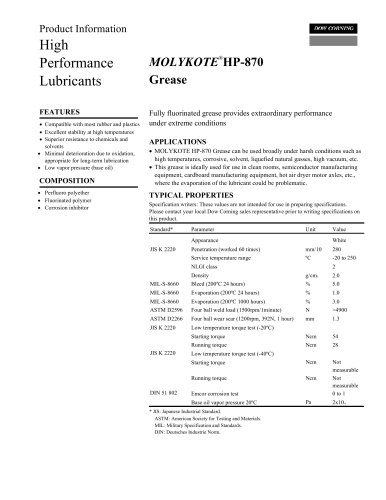

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages