Catalog excerpts

Product Information Specialty Lubricants FEATURES • Wide service temperature range • Compatible with many plastics and elastomers • Meets Cincinnati Machine P-64, and NLGI GC-LB • Fully synthetic base oil BENEFITS • Formulated to provide higher load carrying capacity, greater wear resistance and longer service life compared to conventional petroleum-based lubricants • Provides good compatibility with most industrial and engineering substrates including many plastic and rubber materials • Designed to handle extreme loads and applications involving vibration and/or shock loading • Excellent low temperature torque Molykote® G-4700 Extreme Pressure Synthetic Grease APPLICATIONS • General purpose light consistency black synthetic grease can be used in rolling element and plain bearings, pivot pins, cams, guides, ways, drive screws, gears, splines and other machine elements. TYPICAL PROPERTIES Specification Writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product. Test* DIN 51 818 ASTM D217 ASTM D445 ASTM D445 ISO 2811 Unit Result mm/10 cSt cSt g/ml 2 265-295 150 20 0.87 °C °F °C °F wt% wt% Nm -40 to 177 -40 to 350 >285 >545 3.9 0.44 .024 ASTM D2265 Dropping point FD 791-32/2 FD 791-32/2 Oil bleed, 24 hours, 100°C (212°F) Oil evaporation, 24 hours, 100°C (212°F) Low-temperature torque at -40°C (-40°F) Load Carrying Capacity, Wear Protection, Speed Four-ball wear, 40kg, 1200rpm mm Four-ball EP, weld load, minimum N Dn, bearing ID (mm)x(rpm), estimated ASTM D4693 COMPOSITION • PAO base oil • Lithium complex thickener • Fortified with molybdenum disulfide (MoS2) Property Consistency, Viscosity, Specific Gravity NLGI consistency class Penetration at 25°C (77°F) (W/60) Base oil viscosity at 40°C (104°F) Base oil viscosity at 100°C (212°F) Specific gravity at 25°C (77°F) Temperature Temperature range (approximate) ASTM D2266 ASTM D2596 0.64 3,700 350,000 *DIN: Deutsche Industrie Norm. ASTM: American Society for Testing and Materials. ISO: International Standardization Organization. DESCRIPTION HOW TO USE Molykote® G-4700 Grease is an extreme pressure synthetic grease that combines the benefits of wide operating temperature range and broad compatibility with varied materials. It is thickened with a lithium complex and contains molybdenum sulfide as a solid lubricant. Molykote G-4700 Extreme Pressure Synthetic Grease can be used to lubricate rolling element and plain bearings, pivot pins, cams, guides, ways, drive screws, gears, splines and other machine elements. Apply using conventional grease application methods, i.e., clean brush, grease gun and manual or automated dispensing equipment. HANDLING PRECAUTIONS PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERIAL SAFETY DATA SHEETS AND CONTAINER

Open the catalog to page 1

LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS AVAILABLE ON THE DOW CORNING WEB SITE AT DOW CORNING.COM, OR FROM YOUR DOW CORNING SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CORNING CUSTOMER SERVICE. USABLE LIFE AND STORAGE When stored at or below 35°C (95°F) in the original unopened containers, these products have a usable life of 60 months from the date of production. PACKAGING INFORMATION This product is available in different standard container sizes. Detailed container size information should be obtained from your...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

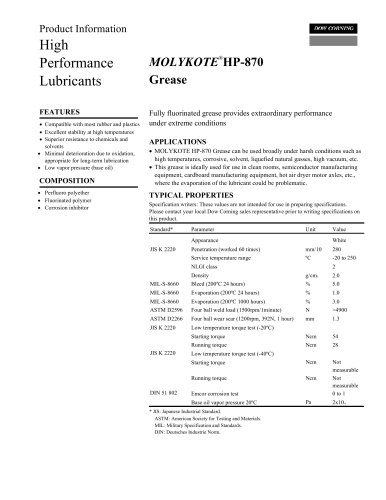

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages