Catalog excerpts

Product Information Specialty Lubricants FEATURES Excellent lubricating properties Good resistance to water washout High load carrying capacity Compatible with many plastics or elastomers Meets FDA Regulation 21 CFR 178.3570 and H1 classification for incidental food contact Available in NLGI consistency class 0, 1 and 2 COMPOSITION Mineral oil Aluminum complex thickener EP/AW additives Molykote® G-0050 FG/G-0051FG/G-0052FG White E.P. Bearing Grease Multi purpose food grade grease APPLICATIONS Multi purpose lubrication of mechanical components such as bearings, chains, gears and slides in food and beverage processing facilities. TYPICAL PROPERTIES Specification Writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product. Test Unit G-0050 White 0 G-0051 White 1 G-0052 White 2 Penetration mm/ 10 370 325 280 Density at 20ºC g/ml 0.89 0.89 0.89 Viscosity @ 40ºC cst 70 70 115 Service temperature DIN 51 818 ASTM D217 ISO 2811 ASTM D 445 Property Color NLGI Consistency -17 to +150 0 to +302 -17 to +150 0 to +302 -12 to +150 0 to +302 Four-ball weld load ºC ºF ºC ºF N 216 420 2940 232 450 2940 246 475 2940 Four-ball wear scar mm 0.8 0.8 0.8 Water wash-out, 175ºF % 15 10 8 ASTM D2265 ASTM D2596 ASTM D2266 ASTM D1264 Fed 791 Drop point Oil bleed, 24 hrs @ 100ºC % 5 3 3 Fed 791 Oil evaporation, 24 hrs @ 100ºC % 2.0 2.0 2.0 ASTM: American Society for Testing and Materials ISO: International Standardization Organization DIN: Deutsche Industrie Norm HOW TO USE Clean points of contact. Molykote® White E.P. Bearing Grease can be applied by hand packing, hand operated grease gun, automatic greasing systems and central lubricating systems. When lubricating antifriction bearings, follow the bearing manufacturers instructions. For plain bearings the new grease should be pumped in until old grease is flushed from system.

Open the catalog to page 1

DESCRIPTION Molykote® White E.P. Bearing Greases are high performance lubricants designed for the food and beverage industry. They are a mineral based lubricant thickened with aluminum complex and fortified with EP additives. Applications include bearings, gears, chains and sliding mechanisms in manufacturing processes. They are an excellent choice where NSF H1 status lubricant is required or when the product must be free of black particle contamination. HEALTH AND ENVIRONMENTAL INFORMATION To support Customers in their product safety needs, Dow Corning has an extensive Product Stewardship...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

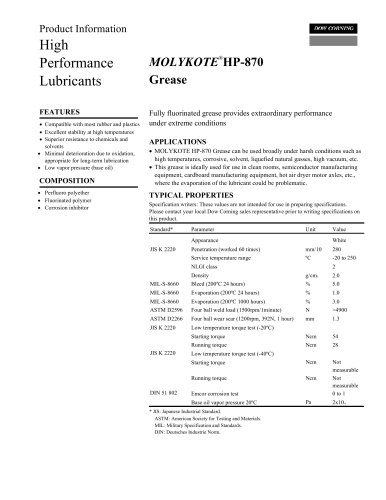

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages