Catalog excerpts

c d Product Information Specialty Lubricants FEATURES " " " " " " Low evaporation Superior oxidation resistance Broad range of service temperatures Superior low-temperature characteristics Compatable with most plastics Water resistant COMPOSITION " Silicone oil " Lithium soap MOLYKOTE® 44L Grease This grease can be used in a broad range of temperatures, and, in particular, can be used on high temperature bearings APPLICATIONS " Ideally suited for use on bearings in oven fans, textile dryers, conveyors, kiln preheaters, etc. Also for use on clutch release bearings for automobiles, plastic parts, and so forth. TYPICAL PROPERTIES Specification writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales representative prior to writing specifications on this product. Standard* Parameter Unit Appearance Value Reddish brown Base oil viscosity at 25ºC mm /s 125 Penetration (worked 60 times) mm/10 290 to 330 Service temperature range ºC -40 to 200 Density g/cm3 1.0 JIS K 2220 Drop point ºC 204 MIL S 8660 Bleed (150ºC/24 hours) % 4.0 MIL S 8660 Evaporation (150ºC/24 hours) % 2.2 JIS K 2220 Oxidation resistance (99ºC/500 hours) MPa 0.01 JIS K 2220 Water washout % 0.5 Maximum Dn value mm/ minute 350,000 JIS K 2220 2 NLGI class 1 to 2 *JIS: Japanese Industrial Standard. ASTM: American Society for Testing and Materials. MIL: Military Specification and Standards. HOW TO USE Clean points of application. As is usual with lubricating greases, apply or fill by means of a brush, spatula, or automatic lubrication device. HANDLING PRECAUTIONS This product may irritate the skin or eyes. Wear safety equipment as necessary when handling this product. In the event of contact with skin or eyes, immediately rinse thoroughly with water and seek medical care if necessary. Wash hands thoroughly after handling. Do not use on painted surfaces

Open the catalog to page 1

When stored, unopened in a cool, dark place this product, has a usable life of 36 months from the date of production. This product is available in 1kg cans 1. Data included in this document are average values, not specification values. Any applications for this product given in this document are merely examples. Perform thorough evaluations to confirm functionality, effectiveness, and safety before use. 2. No guarantees are made that the applications described in this document are free from infringements of any 3. This product was developed for 4. Be sure to read the material safety data...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

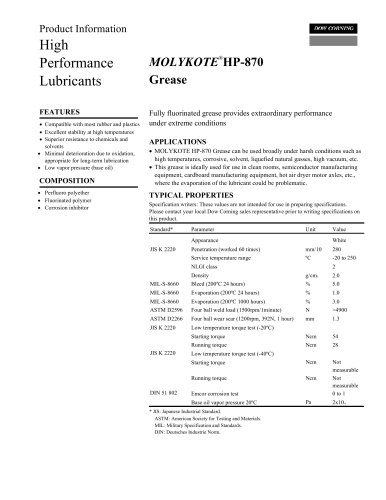

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages