Catalog excerpts

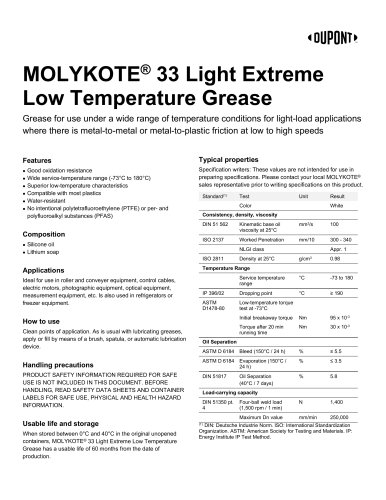

MOLYKOTE® 33 Light Extreme Low Temperature GreaseGrease for use under a wide range of temperature conditions for light-load applications where there is metal-to-metal or metal-to-plastic friction at low to high speedsFeatures • Good oxidation resistance • Wide service-temperature range (-73°C to 180°C) • Superior low-temperature characteristics • Compatible with most plastics • No intentional polytetrafluoroethylene (PTFE) or per- and polyfluoroalkyl substances (PFAS) • Lithium soap Ideal for use in roller and conveyer equipment, control cables, electric motors, photographic equipment, optical equipment, measurement equipment, etc. Is also used in refrigerators or freezer equipment. Clean points of application. As is usual with lubricating greases, apply or fill by means of a brush, spatula, or automatic lubrication device. PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. When stored between 0°C and 40°C in the original unopened containers, MOLYKOTE® 33 Light Extreme Low Temperature Grease has a usable life of 60 months from the date of production. Typical properties Specification writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE® sales representative prior to writing specifications on this product. ASTM Low-temperature torque Initial breakaway torque Nm 95 x 10-3 running time Load-carrying capacity DIN 51350 pt. Four-ball weld load N 1,400 Maximum Dn value mm/min 250,000 DIN: Deutsche Industrie Norm. ISO: International Standardization Organization. ASTM: American Society for Testing and Materials. IP: Energy Institute IP Test Met

Open the catalog to page 1

Packaging This product is available in different standard container sizes as shown on molykote.com. Detailed container size information should be obtained from your nearest MOLYKOTE® sales office or MOLYKOTE® distributor. DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de Nemours, Inc. unless otherwise noted. © 2002-2024 DuPont. The information set forth herein is furnished free of charge and is based on technical data that DuPont believes to be reliable and falls within the normal range of properties. It is...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

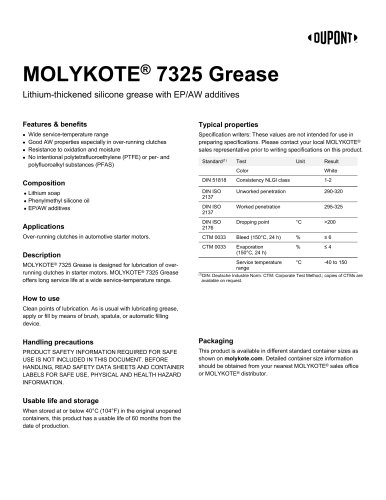

MOLYKOTE® 7325 Grease

2 Pages

-

MOLYKOTE® 7325 Grease

2 Pages

-

Molykote ® Z Powder

2 Pages

-

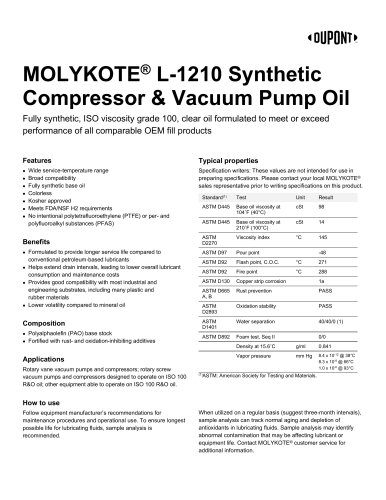

MOLYKOTE® L-1210 Synthetic

2 Pages

-

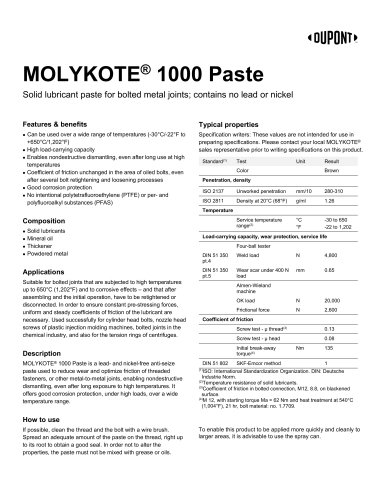

MOLYKOTE® 1000 Paste

2 Pages

Archived catalogs

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

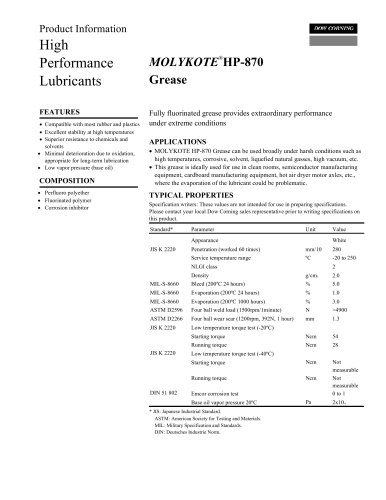

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

-

Molykote® Industrial Lubricants

52 Pages