Catalog excerpts

Plastics & Composites Dow Corning Silicone-Based Additives for Polyamide Compounds Improved Scratch Resistance and Slip Performance in Polyamide Compounds While Dow Corning 31-441 Additive offers some enhancement to anti-scratch properties, it also excels in imparting high slip properties at low loadings. Testing has shown Dow Corning® MB50-011 Masterbatch to be the more efficient anti-scratch additive. Which is best for you depends on the application. Do you need to improve both scratch resistance and slip performance of polyamide compounds? Dow Corning® 31-441 Additive improves both, offering: • Instantaneous and stable benefits • Long-term efficiency Features & Benefits • Off-white solid silicone polymer • Improves scratch resistance • Processing aid to lower torque Figure 1: Dow Corning 31-441 Additive Slip Performance • Automotive components • Electrical and electronics • For improved coefficient of friction in the extruding or injection 0.1 process, Dow Corning 31-441 Additive is the better choice. Loading Scratch Resistance (%) Coefficient of Kinetic Friction • Other glass fiber polyamide applications Coefficient of Kinetic Friction • Processing aid to improve mechanical performance • Reduces coefficient of friction • For anti-scratch improvement of glass fiber polyamide (GFPA), 0.2 Dow Corning MB50-011 Masterbatch is the better choice. PA-GF30 – Reference Dow Corning® 31-441 Additive Dow Corning® MB50-011 Silicone Masterbatch Competition 1 Competition 2 AS Loading (%) PA-GF30 – Reference Dow Corning® 31-441 Additive Dow Corning® MB50-011 Silicone Masterbatch Competition 1

Open the catalog to page 1Different Needs, Different Options Many Solutions. One Source. Table 1: Dow Corning 31-441 Additive and Dow Corning MB50-011 Masterbatch Key Properties ® Competitor 1 Competitor 2 Optimum loading in % by weight A longtime global leader in developing innovative new silicon-based solutions, Dow Corning offers a variety of solutions to plastic and composite formulators. Our additive portfolio offers property enhancement, processing aids and modifiers — in liquids, powders and pellets and our customer service and technical support can help you invent the future. Influence on tensile strength*...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

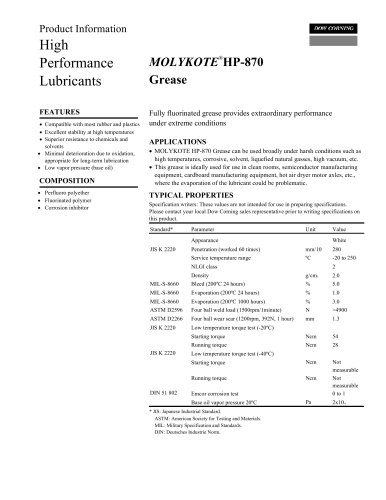

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages