Catalog excerpts

Dow Corning Plasma Solutions’ unique and proprietary use of liquid precursors within the plasma provides profound benets unmatched by other plasma providers. Dow Corning Plasma Solutions technology delivers: • Enhanced product performance and/or new product development through custom surface functionalisation • Reduced processing costs through replacement of wet- and heat-based systems • Health, safety and environmental benets from a process that is dry and energy efcient with low raw material consumption and waste Dow Corning Plasma Solutions As a highly aggressive medium that attacks and breaks up molecular species, the use of plasma to put down functional coatings has historically been limited to elements or low molecular weight compounds. Because of this, outside of highly specialised applications able to use these simple coatings (such as microelectronics), industry has been slow to widely adopt plasma processing despite its many advantages. Meeting customers’ needs Innovative technology from Dow Corning Plasma Solutions has removed the roadblocks to coating sophistication, functionality and value so that a wide range of super-functional, high molecular weight, and even bio-functional, nano-coatings can now be delivered to meet customers’ needs. Like nothing else out there Unlike other plasma surface engineering techniques that rely upon gas state precursors or apply liquid to the substrate either before or after (but not in) the plasma, Dow Corning’s nano-coating process sprays atomised droplets of liquid precursor directly into the room-temperature plasma at atmospheric pressure. The liquid precursor supplies the chemistry while the plasma polymerises, crosslinks and bonds the precursor to the surface to deliver the functional coating. Dow Corning Plasma Solutions’ unique and proprietary use of liquid precursors within the plasma provides benets unmatched by other plasma providers: • Because the number of liquid state precursors is vastly higher than gas state precursors, Dow Corning’s technology provides users with a larger range of surface engineering chemistries and properties than other surface engineering techniques. • The coating rate is much higher than that of gas plasmas, ensuring high throughput and reduced cost. • The delivery of liquid droplet precursor at atmospheric pressure protects the precursor at the molecular level from damage, destruction and denaturing by the plasma.

Open the catalog to page 1

Unmatched versatility The high-technology surface engineering experts from Dow Corning Plasma Solutions can deliver nano-coating-based solutions to customers in many industry sectors including textile, nonwoven, paper, lm, foil, medical, automotive, electronics, sensor and environmental. And because our process is carried out under atmospheric pressure, it: • Ensures compatibility with industry manufacturing needs Dow Corning Plasma Solutions equipment congurations allow the application of many process platforms in a completely surface-specic manner without affecting bulk material...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

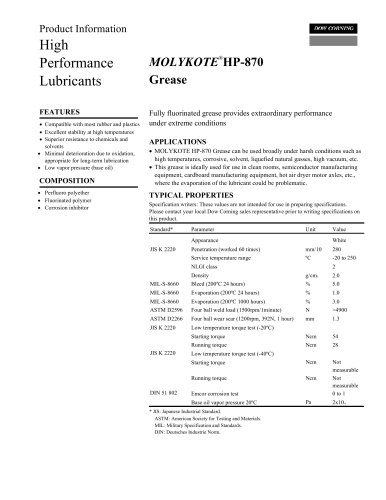

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages