Catalog excerpts

Design guide to optimize rear grommet sealing of electrical connectors with

Open the catalog to page 1

INTRODUCTION DISCUSSION ® The properties of Dow Corning brand GT gels make them excellent candidates for sealing automotive electrical connectors. However, in any sealing application, the seal and the item being sealed are a system and cannot be treated independently. This is also the case with gel seals for electrical connectors. The seal and the connector must be compatible and work together to achieve adequate sealing. Dow Corning GT gels are ideal for use as both rear sealing grommets and interfacial seals for automotive connectors. The design considerations associated with interfacial...

Open the catalog to page 2

pads and sealant strips are supplied either as precision stamped grommets or pre-stamped shapes that are used for automated pick-and-place applications or as continuous, slit rolls that are used for automated stamp-and-place applications. GEL SEAL APPLICATION EVALUATION No material is a universal solution. Gels are not the best sealing solution in all cases. The following application features characterize the automotive connector market. The ability of a gel to seal any given application is characterized by its compatibility with these application features. Contact Type Connectors are...

Open the catalog to page 3

Contact Count Functionally, the performance of gel seals is not affected by contact count. Gel seals perform equally well for low contact count connectors as for high contact count connectors. In addition, performance is not affected by the connector loading factor. Connector size and contact count can affect the economics of gel seals. Small and irregular shapes can be less economical to produce. Gel seals readily seal connectors with reduced contact pitch. Reducing pitch allows downsizing of connectors and becomes a greater benefit as the connector size increases. Connector Type Gels...

Open the catalog to page 4

I Twinned Wires In some cases two wires are terminated to a single contact. Typical rubber seals, either individual wire seals or monoblocks, cannot seal to twinned wires. Although significant work has been done in this area, gels have not yet shown an ability to reliably seal to twinned wires. CONNECTOR DESIGN CONSIDERATIONS New connectors can easily be designed to accommodate gel grommet seals, and existing connectors can be modified to accept gel seals with relatively minor tooling changes. A simple rectangular connector with two rows of contacts will be used as an example. This is for...

Open the catalog to page 5

Edge Distance For 0.6 mm and 1.5 mm contacts, testing has shown that the recommended edge distance is 2.0 mm. Smaller edge distances are acceptable in some connector configurations; however, some reduction in sealing performance might be experienced and size tolerances become more critical. Edge distances larger than 2.0 mm do not significantly improve sealing performance. Corner Radii Sharp corner radii should be avoided to enhance sealing performance. A minimum of 0.5 mm radius is recommended. Larger radii are better. Seal Cavity Depth The gel grommet seal must be contained and put under...

Open the catalog to page 6

Grommet Compressed Height Based on the pressure versus compressed height and the minimum design pressure of 10 N/cm2, a maximum compressed height of the gel grommet can be established. The compressed height will vary depending on the details of the connector support structure. Tolerances The connector and the compression cap should be designed to minimize the total tolerance on the compressed height of the gel grommet. The tolerances should be established to ensure that the maximum compressed height established for any given design is not exceeded. This will ensure that an adequate pressure...

Open the catalog to page 7

CONTACT DOW CORNING Dow Corning has sales offices, manufacturing sites, as well as science and technology laboratories around the globe. For more information, please visit dowcorning.com for addresses and phone numbers of locations in your geography. Or send us an e-mail at dowcorning.com/ContactUs. Front cover: AV13317, AV07230, AV13168, AV08475 LIMITED WARRANTY INFORMATION–PLEASE READ CAREFULLY The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information...

Open the catalog to page 8All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

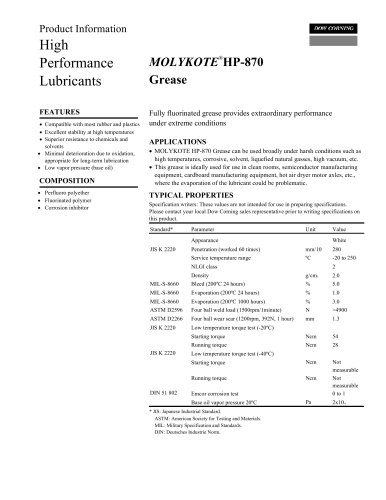

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Total Airbag Solutions

8 Pages

-

Adhesives advertisement

2 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages