Catalog excerpts

Dow Corningf EA-6052 Fast Low-Temp Cure Adhesive and Dow Comincf EA-6054 Thixotropic Fast Low-Temp Cure Adhesive New low-temp, fast-cure adhesives offer throughputs up to three times faster than the industry standard. Speed up your processes or turn down the heat with a new generation of low- temperature, fast-cure silicone adhesives from Dow Corning. Reduce cycle times, energy consumption, and even floor space, while producing a better performing seal. This breakthrough adhesive technology from Dow Corning offers you options for fast process savings. Faster cure time for faster throughput Fast curing shortens cycle times, enabling the production of more modules in the same amount of time. Accelerated curing also allows use of ovens that are shorter and require fewer fixtures than standard ovens, reducing start-up capital costs. Shorter ovens have a smaller footprint, freeing up floor space for other Lower temperatures for reduced operational costs With lower cure temperatures than the industry standard, these products allow the use of low-cost plastics that cannot be used with adhesives that have higher cure temperatures, even while keeping processing times competitive. Improved performance for demanding applications These fast-cure adhesives provide more choices, enabling manufacturers more durable solutions for safeguarding sensitive electronic components in extreme environmental conditions. These silicone products retain their elasticity, ensuring a reliable seal. And the adhesives rapidly adhere to industry-critical substrates such as polyamide, PBT ceramics and aluminum. Low voiding for increased reliability Bubbling caused by evaporated water in plastics and nylon during cure can cause voids and prevent reliable sealing. The low-voiding characteristic of these adhesives provides better moisture tolerance and the low-cure temperature can minimize the evaporation or boil-off of the water from the plastic, eliminating the need to dry the plastic components. Solutions for every need Whatever the need, from sealing lids and housings, attaching base plates orgasket- ing applications, to connector sealing and multiple plane dispensing, this new adhe- sive technology from Dow Corning has you covered - and it's available in flowable To learn about your best solution, visit our website at Fast Low-Temp Cure Adhesives « Reduced voiding « Rapid low-temperature cure Fast Low-Temp Cure Adhesive « Flowable to allow channel Thixotropic Fast Low-Temp Cure Adhesive formulation enables

Open the catalog to page 1

Time to Full Adhesion to Aluminum Dow Coming's new, fast, low-temperature curing adhesives significantly shorten processing time for increased throughput Typical Properties Specification VWiters: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on these products. Elongation, percent Specific Gravity, uncured Unprimed Adhesion, Lap Shear, psi (MPa) Shelf Life at 25°C (77°F), months Dielectric Strength, volts/mil (kV/mm) Volume Resistivity, ohm-cm 'Time to double initial viscosity. LIMITED WARRANTY INFORMATION - PLEASE READ...

Open the catalog to page 2All Dow Corning catalogs and technical brochures

-

2 part RTV

6 Pages

-

Dow Corning and You Belgium

6 Pages

-

Elastomers from Dow Corning

8 Pages

-

Automotive Airbag

8 Pages

-

Molykote ® 1000

2 Pages

-

Molykote ® L-1210

2 Pages

-

Molykote ® Z Powder

2 Pages

-

Molykote? G-4501

2 Pages

-

Dow Corning Code of Conduct

10 Pages

-

Chip Scale Review Reprint

5 Pages

-

From the Pedal to the Pad

8 Pages

-

MOLYKOTE® 7325

2 Pages

-

MOLYKOTE® MH-62 GREASE

8 Pages

-

MOLYKOTE® 7325 GREASE

2 Pages

-

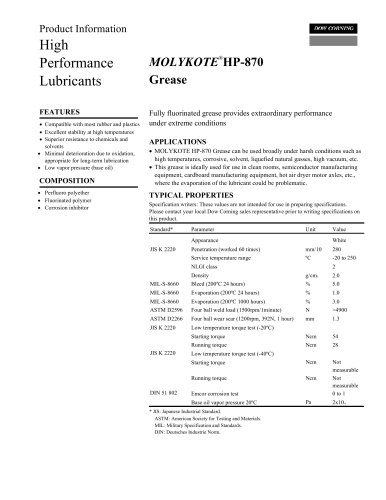

MOLYKOTE® HP-870

2 Pages

-

MOLYKOTE® 33

4 Pages

-

MOLYKOTE® BG-555

4 Pages

-

MOLYKOTE® G-0050

2 Pages

-

MOLYKOTE® 44

2 Pages

-

Molykote® 1292

2 Pages

-

MOLYKOTE® BR 2

2 Pages

-

Automative

4 Pages

-

Dow Corning Plasma Solutions

2 Pages

-

Design guide to optimize

8 Pages

-

Total Airbag Solutions

8 Pages

Archived catalogs

-

Molykote® Industrial Lubricants

52 Pages