Website:

DOSOMAC

Website:

DOSOMAC

Catalog excerpts

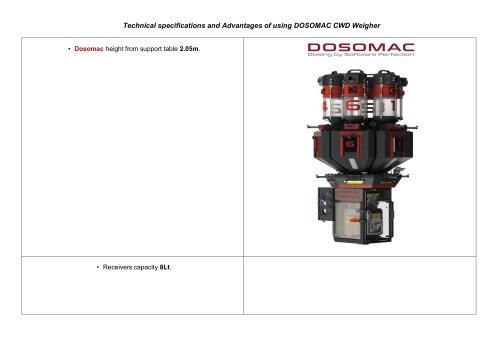

Technical specifications and Advantages of using DOSOMAC CWD Weigher • Dosomac height from support table 2.05m.

Open the catalog to page 1

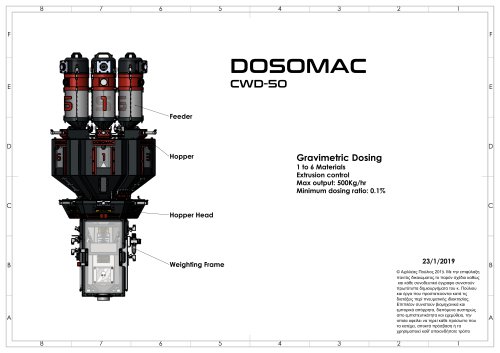

• Dosing and mixing, with per gram weighing of all materials, with absolute accuracy and continuous mixing. • Saving at least 20% in master batch and additives. • Mixing of all materials with 0.1% accuracy. • Per gram weighing of material during the feeding of the extruder and automatic production control. • Extrusion Control Automatic set up and operation of the Extruders. The operator sets the desired film thickness and kilos per hour. DOSOMAC CWD does the rest automatically. Controls the screw rotations, hence the quantity of the material. Also controls the torque of the puller, hence...

Open the catalog to page 5

• Easy access to all mechanical parts of DOSOMAC CWD is ensured for cleaning and maintenance. • Easy to use, due to its simplified interface

Open the catalog to page 6

• Fully modular design for easy conversion from 2 to 8 materials.

Open the catalog to page 7

• Reduced installation cost with integrated factory wiring. • Fully automated system for material loading to receivers with use of threephase vacuum pump. • Integrated mixing bin with specially designed stirred for optimal homogenisation of the ble

Open the catalog to page 8

• Dosomac support table for reduced vibrations (enhanced accuracy), as well as for easy access of the operator for maintenance purposes. • 36.3 Lt buffer for connection between the cannon entrance and Dosomac with material exit on the side

Open the catalog to page 9All DOSOMAC catalogs and technical brochures

-

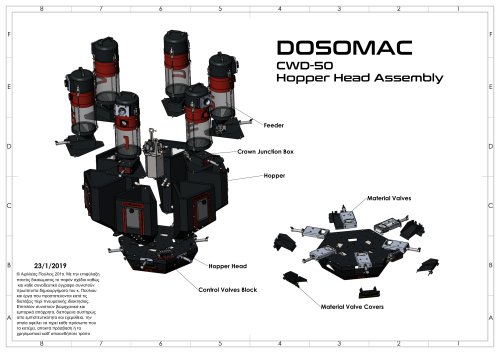

DOSOMAC CWD-50

1 Pages