Catalog excerpts

P1 rapier weaving machine Quality creates value

Open the catalog to page 1

future „Quality creates value“ – the DORNIER rapier weaving machine has set the technological standard in the high quality home textiles market for decades. Practically everything which can be wound on bobbins is efficiently converted into high quality woven fabric on this machine. Its success story is consistently continued with the new DORNIER P1 rapier weaving machine.

Open the catalog to page 2

DORNIER P1: PRODUCTIVITY WITH MAXIMUM FLEXIBILITY Immediate reaction to market requirements – in this respect the new P1 rapier weaving machine opens up every possibility. Thanks to its ease of operation and reduced maintenance cost, it can be adapted even more quickly to any fabric. Its setting consistency provides for rapid production starts on new articles, enabling optimum fabric quality to be achieved in the shortest possible time – even when using complex yarns. Its unsurpassable processing reliability guarantees high productivity at the same time as maximum flexibility. The new...

Open the catalog to page 3

filling insertion DORNIER RAPIER FILLING INSERTION: THE SUPERIORITY OF THE TRIED AND RELIABLE SYSTEM Filling insertion with positively controlled center transfer is the heart of the P1 rapier weaving machine. The filling is picked up and transferred precisely and reliably through the open shed and held securely until bound in. The human hand as the model With positive center transfer, the rapier motion is precisely controlled via complementary cam gear boxes. The open left-hand clamp of the left hand rapier grips the yarn presented by the filling selector needle before entering the shed....

Open the catalog to page 4

Immediate machine start after product change Reliable pick and pick yarn insertion of fine to coarse yarns and positively controlled yarn transfer from left-hand to right-hand rapier in every phase: Indispensable prerequisites for immediate machine start without readjustment after product change, or even on-the-fly pattern change with the machine in operation. Safety though precision Two synchronously operating high-precision gearboxes are located on both sides of the machine for filling insertion and reed beat-up. They ensure optimum rapier and reed motion with the proven, reliable center...

Open the catalog to page 5

filling insertion UNSURPASSED: DORNIER WOVEN FABRIC QUALITY Minimal filling breakage figures, no tension distortion and spring-back picks – the DORNIER rapier system has decisive qualitative and economic advantages in day to day’s operation. Low tensile strength yarns can be processed without difficulty. In other respects, robust filling insertion component construction provides for the reliable processing also of heavy industrial yarns. Better quality brings more profitable orders - Quality creates value. Wide application range Filling insertion controlled at every stage enables an...

Open the catalog to page 6

Precision-controlled transfer Soft clamps with a hard metal insert and precisioncontrolled transfer – even coarse 2200 dtex filaments with 450 individual capillaries are securely clamped and inserted. Filling yarn tension level: Best by all standards The yarn tension level of the DORNIER P1 rapier weaving machine is lowest. Compared to all existing negative rapier weaving machines, the DORNIER positive rapier system remains superior in terms of basic tension level, making the best possible filling yarn breakage figures attainable. Filling yarn tension level during insertion: other negative...

Open the catalog to page 7

filling insertion SAFETY: IN EVERY FILLING INSERTION PHASE The P1 solves filling insertion component guidance to perfection: The patented DORNIER AirGuide® guides the rapier with precision in the shed, consequently preventing capillary damage in the case of filament warps, and even enabling high warp densities to be woven problem-free. The ECS electronic color selection system and the electronic yarn brake with integral filling stop motion EFC are based on modern stepping motor technology. Due to the modular construction, individual modules can be quickly and easily added. In this way, a...

Open the catalog to page 8

Precision, thanks to ECS With the new ECS color selector motor technology, yarn presentation is effected in micro step resolution with an automatic yarn needle motion monitoring and correcting function. The needle´s smoothly controlled movement allows gentle yarn presentation with reduced yarn tension peaks. Low tensile strength yarns and also heavy yarns with high yarn tension, like 2400 tex glass for example, can be processed without difficulty. Different motion profiles can be conveniently selected on the DORNIER ErgoWeave® . EFC highly dynamic yarn brake The optional electronic EFC yarn...

Open the catalog to page 9

CONTROL SYSTEM FT CONTROL SYSTEM AND DORNIER ERGOWEAVE ®: COMPLEX TECHNOLOGY PROVIDES EASY HANDLING Born out of practice, the new DORNIER ErgoWeave® operating concept enables for intuitive machine handling for the first time. The innovative FT control system newly developed for it forms the foundation stone for significant further improvements in the most diverse variety of sub-assemblies. It guarantees high reliability and efficiency in woven fabric production – with a technology which is open to future developments. Fast-Ethernet-Technology control system: Innovative and fit for the...

Open the catalog to page 10

USB and Ethernet interface The recording of pattern and product data, as also the loading of new configurations and software, is effected simply and conveniently via USB-Stick. The weaving machine can be linked with all customary operating data systems, or connected to a network, via an integrated mass-produced Ethernet interface. The DORNIER ErgoWeave®’s pattern storage volume records up to one million pick repeats – and can be further extended. DORNIER ErgoWeave®: Intuitively operable touch screen The software is operated via a spacious, user-friendly designed 15 inch touch screen....

Open the catalog to page 11

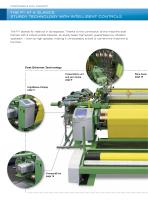

COMPONENTS WITH CONCEPT THE P1 AT A GLANCE: sturdy technology with intelligent controls The P1 stands for reliance in all respects. Thanks to the connection of the machine side frames with a robust profile traverse, its sturdy basic framework guarantees low vibration operation – even at high speeds, making it unnecessary to bolt or cement the machine to the floor. Fast Ethernet Technology Presentation unit and yarn brake page 9 ErgoWeave-Display page 11 Warp beam page 18

Open the catalog to page 12All DORNIER GmbH catalogs and technical brochures

-

ServoTerry

16 Pages

-

P2

17 Pages

-

P1 & A1

2 Pages

-

A1

13 Pages

-

DRYER

16 Pages

-

FILM STRETCHING LINE

10 Pages

-

DORNIER EASYLENO®

6 Pages

-

The rapier weaving machine P1

24 Pages

-

Open Reed Weave (ORW)

4 Pages

-

TIRECORD

6 Pages

-

EasyLeno®

5 Pages

Archived catalogs

-

ServoTerry®

12 Pages

-

A1 Air-Jet

24 Pages