Website:

DOPAG - Metering, Mixing and Dispensing Technology

Website:

DOPAG - Metering, Mixing and Dispensing Technology

Group: HILGER & KERN GROUP

Catalog excerpts

lubriLine SOLUTIONS FOR THE METERING AND DISPENSING OF LUBRICANTS

Open the catalog to page 1

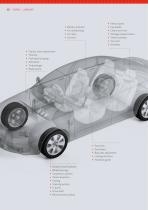

Battery terminal Air conditioning Air vents Sunroof Interior parts Cup holder Centre arm rest Storage compartments Switch systems Sun visor Glovebox Starter, start-stop button Throttle Fuel injection pump Alternator Turbocharger Water pump Double-mass flywheels Wheel bearings Suspension system Shock absorbers Sealing Steering system U-joints Drive shaft Belt tensioner pulleys

Open the catalog to page 2

High precision application of lubricants Every task has a perfect solution Typically, the production of a single vehicle will involve over 150 grease and oil applications. Depending on the specific car model, there can be even more. The purpose of lubrication is the reduction of friction, noise prevention, component durability and the general smooth running of a vehicle. Each application carries a unique set of parameters and so the designing of a metering system always needs to take numerous factors into account. For example, is the material being applied in a dot, bead or spray form? What...

Open the catalog to page 3

Products for every part of the process

Open the catalog to page 4

Material feeding A reliable supply of grease and oil

Open the catalog to page 6

If we want to achieve perfect results with grease and oil metering, it is important that our material be pumped efficiently and without air pockets (air bubbles). An uninterrupted and reliable material supply is absolutely essential to achieve that. With every application, the selection of an optimum feeding system must consider factors such as material properties, process parameters and container size. The DOPAG product portfolio offers an extensive range of solutions for fluid metering, including drum pumps, transfer pumps and pressure tanks. All DOPAG feeding systems rely on the proven...

Open the catalog to page 7

Drum pumps An efficient supply of lubricants DOPAG has developed a special range of drum pumps for the processing of lubricants. The lubriLine pump range features double-acting ball valve and piston pumps that deliver greases and oils of consistency class NLGI 0 - 3. Material is fed directly from original containers. LubriLine grease pumps are an ideal Supply of low to medium viscosity materials Flow rate up to 1.2 litres/minute at 40 double strokes Compatible with lubricants of NLGI class 0 – 3 Differential piston pumps with fast-switching air motors Modular design with configurable...

Open the catalog to page 8

High performance piston pumps This drum pump model is available exclusively as a double-acting chop check pump. Along with greases and oils, it also processes adhesives, sealants, polyurethanes or silicones with viscosities of up to 5.0 million mPas. Material is fed directly from the original Supply of medium to high viscosity material Flow rate up to 6 litres/minute at 20 double strokes Max. viscosity 5 million mPas Differential piston pumps with fast-switching air motors Modular design with configurable components Sealing available in various sizes and material finishes containers. The...

Open the catalog to page 9

Tandem pumps Many applications require an uninterrupted material feed maintained at all times. For such cases, all DOPAG pump models are available as a tandem version. Tandem pumps feature an automatic mechanism that switches between the pumps whenever material level is low, so that container change can proceed without interruption and time pressure. With clean handling and minimal material residue left in the drum, DOPAG pumps have earned their place in the most efficient production lines around the world. All sizes are available as tandem versions. Pump configuration with the ID Generator...

Open the catalog to page 10

Transfer pumps for direct supply from original containers Depending on the application type, it may be useful to be able to supply material directly from the original containers using a transfer pump. DOPAG transfer pumps are doubleacting pumps with a fast-switching air motor. It should be Low viscosity material feeding via bung hole Flow rate up to 1.0/6.0 litres/minute at 20 double strokes Sealing available in various sizes and material finishes noted that the use of transfer pumps is always dependent on the material properties and the container t

Open the catalog to page 11

Pressure tanks Thin fluids delivered effortlessly Low-viscosity media such as oils can be delivered to the point of application directly from pressure tanks by means of compressed air. The tanks can serve either as buffer storage within a metering system or as the main system supply. They are available in various sizes and with options, to accommodate different application requirements. With visual level indicators and electric level sensors, you will always be aware how much material is left in the tank. Alternatively, DOPAG pressure tanks are also available with mounting fixtures. Product...

Open the catalog to page 12

Material pressure regulators Pulsation-free dispensing with the correct pressure DOPAG material pressure regulators reduce the pressure of the pumped material down to the optimum working value. They are designed specifically for the precise dosing of greases, oils and silicones. Along with reducing pressure, the valves also compensate for pulsations that occur when material is delivered via piston pumps, more specifically in the moment of the changeover position of the pump. This problem Product features manifests itself in fluctuations in material pressure and flow, and can lead to reduced...

Open the catalog to page 13

Metering and dispensing As precise as you need

Open the catalog to page 14

Metering and dispensing valves from DOPAG demonstrate all the qualities that are essential for optimum results in metering: high precision, excellent reproducibility and high quality standards. The DOPAG range includes various valve types, all of which are based on one of two dispensing principles. The needle and chamber metering valves work on the volumetric principle (dot application). Here, each cycle means that the contents of the valve chamber are completely emptied upon a trigger signal. This has the advantage of high repetition accuracy and flexibility thanks to the possibility of...

Open the catalog to page 15

Needle metering valves Greater accuracy for small dot size Needle metering valves are suitable for dot application of low to high viscosity media. With this series, very small quantities of up to 3ml per shot can be discharged with high reproducibility and short cycle times. The valve consists of two structurally separate parts, meaning that material cannot leak into the drive cylinder and interfere with the movement of the valve needle. This feature makes the needle metering valve an exceptionally reliable and low-maintenance piece of metering equipment. Shot size is determined by the...

Open the catalog to page 16All DOPAG - Metering catalogs and technical brochures

-

Drum pumps

12 Pages

-

variomix

6 Pages

-

LSR silcomix

12 Pages

-

ladomix G-SF

4 Pages

-

coredis

4 Pages

-

Coatingmix

4 Pages

-

vectomix TC

2 Pages

-

vectodis vectomix

2 Pages

-

glueLine

23 Pages

-

automationLine

8 Pages

-

Volumix

4 Pages

-

Brochure rotordis rotormix

6 Pages

-

eldomix 100 / 600

6 Pages

-

Wind power industry

13 Pages

-

dynamicLine

28 Pages

-

dynamicLine E

4 Pages

-

evomix DF

2 Pages

-

compomix FI

2 Pages