Website:

DOPAG - Metering, Mixing and Dispensing Technology

Website:

DOPAG - Metering, Mixing and Dispensing Technology

Group: HILGER & KERN GROUP

Catalog excerpts

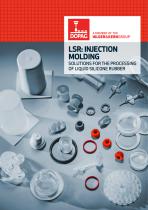

SOLUTIONS FOR THE PROCESSING OF LIQUID SILICONE RUBBER

Open the catalog to page 1

02 · DOPAG · INJECTION MOLDING

Open the catalog to page 2

DOPAG · INJECTION MOLDING · 03 We understand the challenge at hand Stability and reliability in continuous use Secure production processes in the case of high loads are a key requirement for your business success. Thanks to robust technology, we ensure that your production runs reliably – with even shorter setup times. The continuously growing demand for silicone products is due to the special properties of the material. For example, it can be reformed even after it has been processed. As high elasticity is needed for many products, this key distinguishing feature compared to other...

Open the catalog to page 3

04 · DOPAG · INJECTION MOLDING The silcomix is a compactly designed, electrically driven piston pump, metering and mixing system. It is used for continuously processing medium to high-viscosity, silicone-based media with a mixing ratio of 100:100. Metering is carried out directly from the original containers with a size of 20 or 200 l. Technical data Outflow rate up to 1.2 or 3.6 l/min (at max. 20 or 12 double strokes per minute and at MR 100:100, depending on viscosity) Mixing ratio 100:100 (further ratios available on request) Color injection metering up to 4 colors with a ratio of 0.2 -...

Open the catalog to page 4

DOPAG · INJECTION MOLDING · 05 Equipment Standard Pneumatic driven rams Drum roll-in unit Follower plate for 200 l containers Drum roller conveyor Static base support Active, pneumatic base support Removable follower plates for 20 l containers Material screens for follower plates Servo-electrically driven piston pumps with ‘SWIPSYNC’ Material pressure monitoring via pressure sensors Automated drum and pump ventilation DOPAG MR40 metering calculator Mixing ratio monitoring (volume measuring cells) System operation via 7” colour touch panel Analogue level monitoring High-pressure material...

Open the catalog to page 5

06 · DOPAG · INJECTION MOLDING

Open the catalog to page 6

DOPAG · INJECTION MOLDING · 07 Revolutionised LSR mixing unit Previously, setup work on LSR mixing units was a complicated process that took a long time. It was a job that required tools and sometimes even needed the involvement of several workers. Thanks to the new mixing unit for the silcomix LSR metering system, this has changed fundamentally. The new design is unique on the market and simplifies operation while ensuring shorter setup times and greater system availability. Maintenance time and intervals can be reduced by up to 75 per cent. The low-viscosity silicones increasingly being...

Open the catalog to page 7

08 · DOPAG · INJECTION MOLDING Reliable components Reliable components for a stable production process Base support Ventilation Follower plate 200 l Ventilation pump Ventilation Follower plate 20 l Material screen Pigment supply 1 l beneath follower plate (strainer/optimised for residual quantities) Pigment supply with plastic container and piston pump Pigment valve Volume counter Pigment metering Control panel Process data information Flow chart

Open the catalog to page 8

DOPAG · INJECTION MOLDING · 09 Precise SWIPSYNC Synchronous switching of servo-electrically driven piston pumps for precise adherence to mixing ratio ensures uniform drum drainage of the A and B components. The collapse in pressure flow, and thus also volume flow, is considerably reduced through a special control of the servo drives, with the time also significantly shortened. Pressure / volume flow The servo-electrical drive enables synchronous switching of the piston metering pumps, regardless of the current position of the respective pump piston (switching point synchronisation). This...

Open the catalog to page 9

Our silcomix is used in many different industries and applications Automotive industry e.g. seals on car keys, general connector seals, valves, membranes, LED lens optics, cable harness seals Electrical engineering e.g. coatings, various seals for smartphones, watch straps, seals for ‘brown goods’ Household and kitchen e.g. baking moulds, kitchen utensils, various seals for perfume bottles Aviation and aerospace industries e.g. valves, membranes, cable harness seal

Open the catalog to page 10

Baby care e.g. soothers and bottle teats, toys, teething rings, toothbrush handles Medical technology e.g. respirators and syringes, nose pads and temples for glasses, pumps for nose drops, surgical replacement parts (e.g. kidney repair) Sanitary technology e.g. shower heads, shower frame seals (by the yard/metre), valves (fittings)

Open the catalog to page 11

We are one of the world’s most experienced manufacturers of high-quality metering technology. Wherever adhesives, resins, silicones or lubricants are metered and applied in industrial production, we offer reliable, precise solutions. We provide systems and components for highly automated production processes, including for the automotive, wind, household appliances and electrical industries, as well as for aviation. DOPAG is part of the HILGER & KERN GROUP, a reliable supplier and a development and service partner to industrial companies in a variety of market segments for almost 100 years....

Open the catalog to page 12All DOPAG - Metering catalogs and technical brochures

-

Drum pumps

12 Pages

-

variomix

6 Pages

-

ladomix G-SF

4 Pages

-

coredis

4 Pages

-

Coatingmix

4 Pages

-

vectomix TC

2 Pages

-

vectodis vectomix

2 Pages

-

glueLine

23 Pages

-

automationLine

8 Pages

-

Volumix

4 Pages

-

Brochure rotordis rotormix

6 Pages

-

eldomix 100 / 600

6 Pages

-

Wind power industry

13 Pages

-

dynamicLine

28 Pages

-

lubriline

38 Pages

-

dynamicLine E

4 Pages

-

evomix DF

2 Pages

-

compomix FI

2 Pages